Manufacturing method of pyroelectric ultra-thin ceramic chip and application of pyroelectric ultra-thin ceramic chip to sensor

A technology of pyroelectric ceramics and a production method, which is applied in the direction of electric radiation detectors, instruments, scientific instruments, etc., can solve the problems of low production efficiency and high production cost, and achieve the effect of reduced production cost and good performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the manufacturing method of the pyroelectric ultra-thin ceramic sheet involved in this embodiment is as follows:

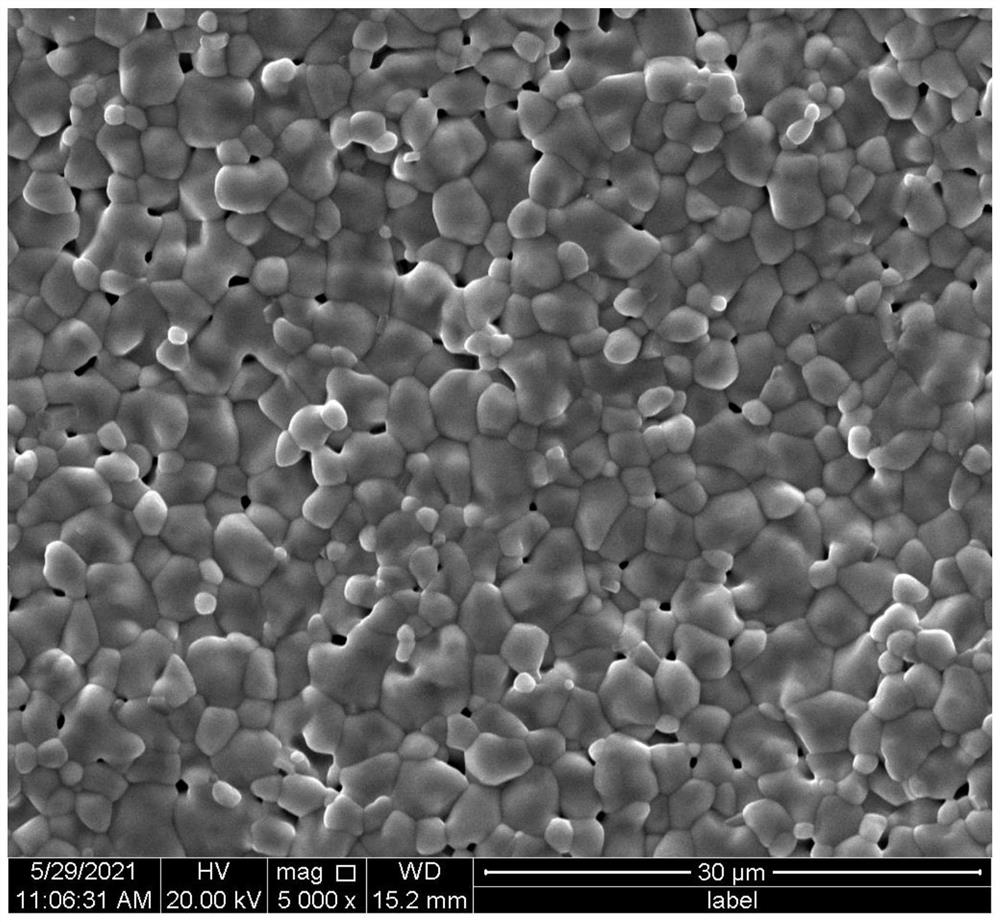

[0035] 1) Add 5000g of pre-fired pyroelectric ceramic powder, 0.5-5wt% sintering aid, 40% ethanol and toluene mixed solution, 0.5wt% KD-1 or other dispersant, and add it to the inside of a 2L nylon ball mill tank And carry out ball milling and mixing for 4-5 hours, add 4-8% PVB binder, continue ball milling for 12-18 hours, measure the particle size with a laser particle size analyzer, and make the particle size within the range of D50=1.2um±0.1um, and pass through 400 mesh Stainless steel screen discharge;

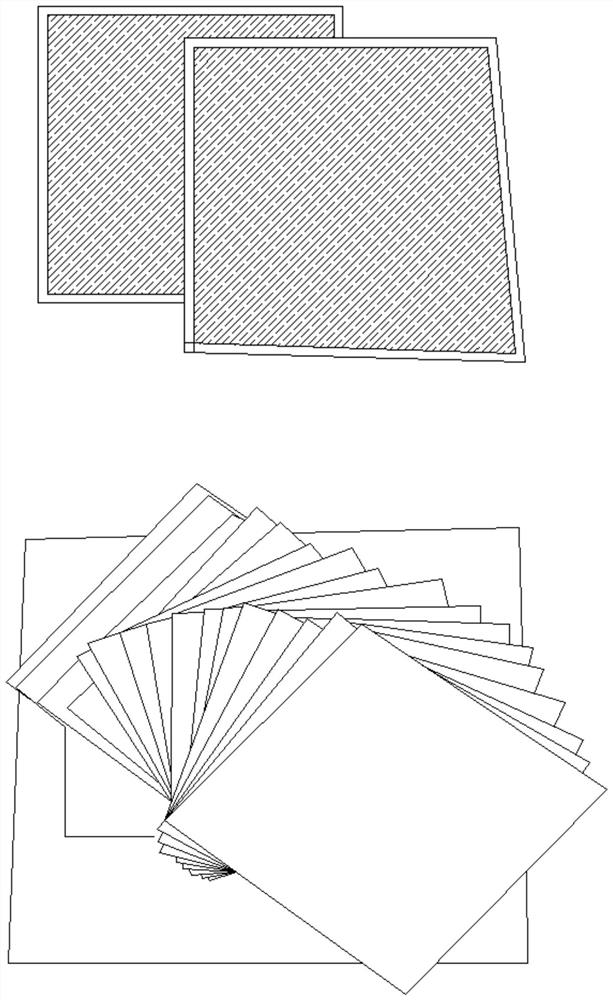

[0036] 2) Vacuumize the slurry for defoaming, and control the viscosity of the slurry at 400cps±100cps, use steel belt casting to form a ceramic green film tape with a thickness of 20-50um, and then cut the film tape into a 200*200mm green sheet. The film strips are cross-laminated in different directions consistent with or perpendicular t...

Embodiment 2

[0044] Embodiment two, the preparation method of the pyroelectric ultra-thin ceramic sheet involved in this embodiment is as follows:

[0045] 1) Add 5000g of pre-fired pyroelectric ceramic powder, 0.5-5wt% of sintering aid, 50% of ethanol and toluene mixed solution, 1.0wt% of KD-1 or other dispersants, into a 10L nylon tank and Use a horizontal planetary mill, mix for 5-6 hours, add 4-8% PVB binder, continue ball milling for 12-18 hours, measure the particle size with a laser particle size analyzer, and make the particle size within the range of D50=1.2um±0.1um, and Discharge through 400 mesh stainless steel screen;

[0046] 2) Vacuumize the slurry for defoaming, and control the viscosity of the slurry at 400cps±100cps, use steel belt casting to form a ceramic green film tape with a thickness of 20-50um, and then cut the film tape into a 200*200mm green sheet. The film strips are cross-laminated in different directions consistent with or perpendicular to the casting directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com