Fixing tool for cold machining based on optical prism and using method of fixing tool

A technology for fixing tooling and prisms, which is applied to optical surface grinders, metal processing equipment, and machine tools suitable for grinding the edge of workpieces, etc. Problems can be fixed and reliable, easy to reset quickly, and the processing efficiency can be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

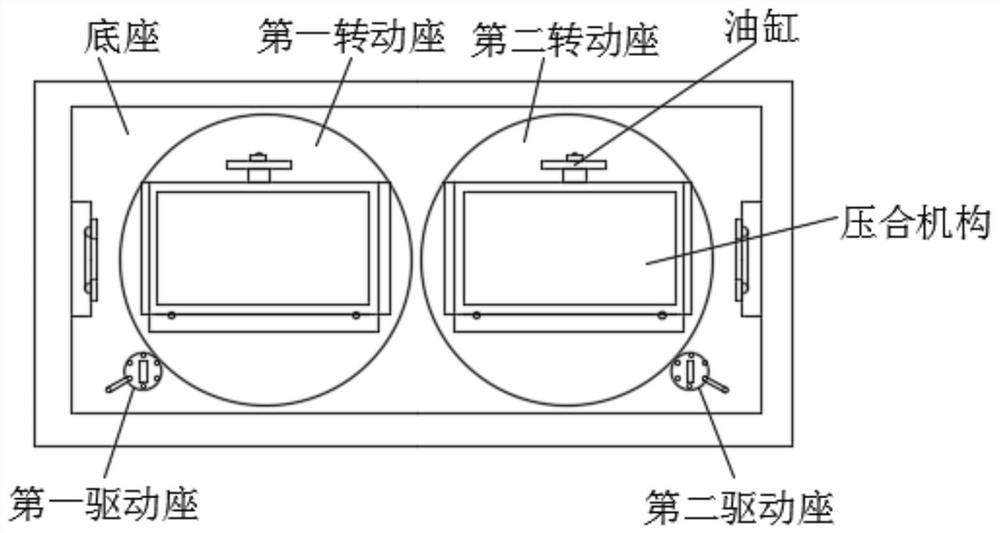

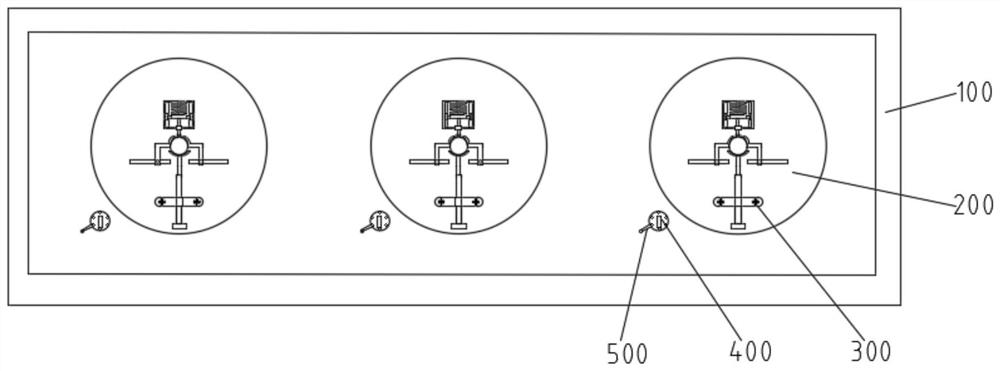

[0027] see figure 2 As shown, the present invention is based on the fixed tooling for optical prism cold processing, including a base 100, the cross section of the base 100 is a square structure, and several rotating seats 200 arranged equidistantly along the horizontal direction are mounted on the base 100, and on the base 100 There are also several adjusting seats 400 that are arranged equidistantly and matched with the rotating seat 200 for rotation, the adjusting seat 400 is located on one side of the rotating seat 200, and the upper surface of the rotating seat 200 is provided with a fixing mechanism 300; the inside of the base 100 A chamber is provided, and both the adjusting seat 400 and the rotating seat 200 extend to the inside of the chamber, and the outer surface of the adjusting seat 400 is provided with a gear near the lower end, and the outer surface of the rotating seat 200 is provided with a gear ring near the lower end. , the gear is meshed with the tooth end...

Embodiment 2

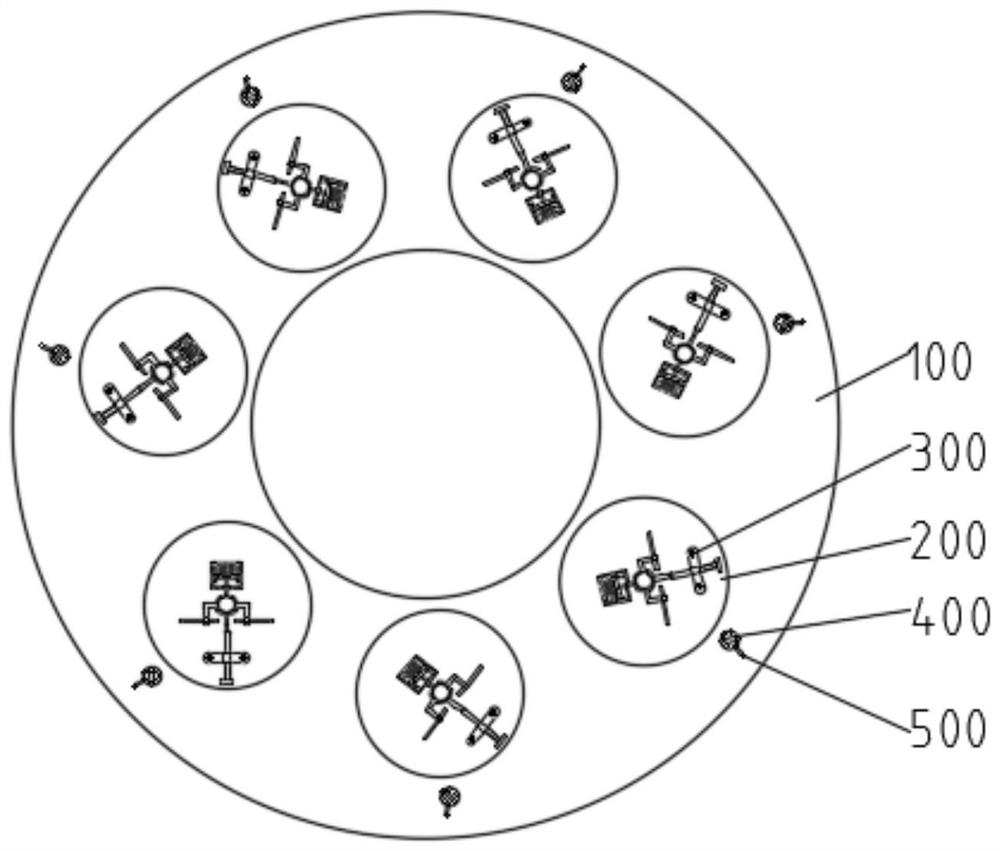

[0031] see image 3As shown, the base 100 is rotatably mounted with several rotating seats 200 arranged equidistantly, and the base 100 is also rotatably mounted with several adjusting seats 400 arranged in a circular array and matched with the rotating seats 200. The adjusting seats 400 Located on one side of the rotating seat 200, the upper surface of the rotating seat 200 is provided with a fixing mechanism 300; the inside of the base 100 is provided with a chamber, the adjusting seat 400 and the rotating seat 200 both extend to the inside of the chamber, and the outer surface of the adjusting seat 400 The position near the lower end is provided with a gear, and the outer surface of the rotating seat 200 is provided with a gear ring near the lower end. The gear is meshed with the tooth end surface of the gear ring, and the outer surface of the adjustment seat 400 is also threaded. The cross-section of the base 100 has a circular structure, so that the inner circular area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com