Die cutting bottom roller, die cutting assembly and automatic die cutting machine

A technology for die-cutting machines and bottom rollers, which is applied in the field of die-cutting components, bottom rollers, and automatic die-cutting machines. It can solve the problems of inability to remove waste materials and reduce processing efficiency, and achieve the effect of improving yield and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

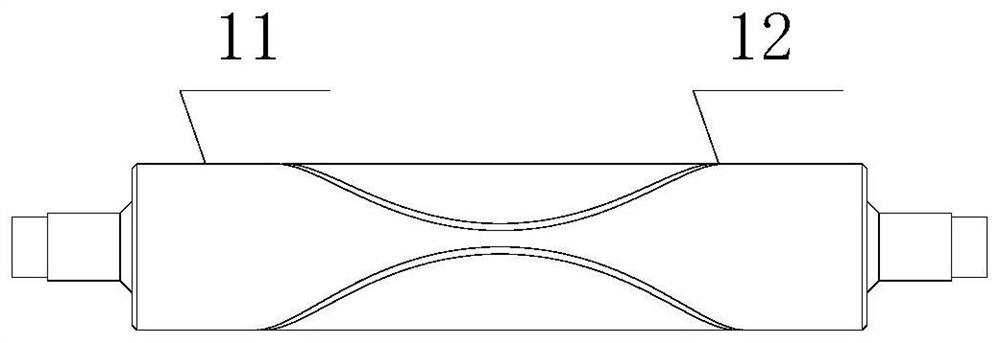

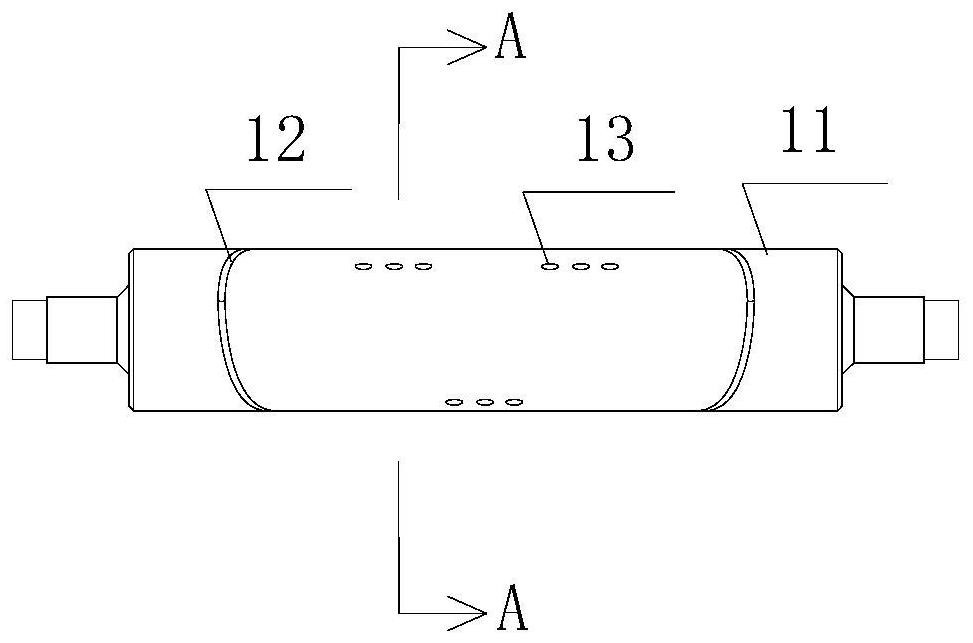

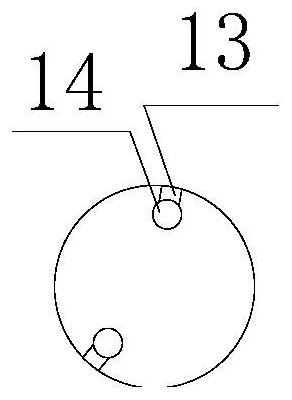

[0064] like figure 1 , figure 2 , image 3 , Figure 4 Shown is one of the embodiment of a kind of die-cutting bottom roller that is used for facial film of the present invention, and this die-cutting bottom roller 1 comprises roller body 11, and described roller body 11 surface has the outer contour cut-off corresponding to the outer contour of facial film Groove 12, described roller body 11 is also provided with suction hole 13, and suction hole 13 is respectively positioned on the position of mask eye, mouth, has air channel 14 in described roller body 11, and described air channel One end of 14 communicates with the outside of the die-cutting bottom roller, and the other end communicates with the suction hole 13.

Embodiment 2

[0066] like Figure 5 , Image 6 , Figure 7 , Figure 8 Shown is the second embodiment of a kind of die-cutting bottom roller for facial film of the present invention, and this die-cutting bottom roller 1 comprises roller body 11, and described roller body 11 surface has the inner contour cut-off corresponding to the inner contour of facial film Grooves 15, the inner contour avoidance grooves 15 include eye contour avoidance grooves, mouth contour avoidance grooves and nose contour avoidance grooves, and the roller body 11 has air suction holes 13, The air suction hole 13 is located on the midline position of the facial mask (it can also be located on other film material positions of the facial mask), and the air suction hole 13 can be communicated with an external suction device during use.

Embodiment 3

[0068] like Figure 9-12 Shown is one of the embodiments of a die-cutting assembly of the present invention, including two die-cutting bottom rollers 1 and a knife roller 2, and the two die-cutting bottom rollers 1 are respectively the first bottom roller A and the second bottom roller A. The bottom roll B, the first bottom roll A and the second bottom roll B surround the periphery of the knife roll 2 and cooperate with the knife roll 2. The knife roll 2 is provided with an outer contour blade 21 and an inner contour blade 22, so The surface of the roller body of the first bottom roller A is provided with an outer contour cutting avoidance groove 12 corresponding to the position of the outer contour blade 21 of the knife roller 2 .

[0069] The surface of the roller body of the second bottom roller B is provided with an inner contour cutting avoidance groove 15 corresponding to the position of the inner contour blade 22 of the knife roller. The depth of the outer contour avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com