Steel wire inner ring machining machine for high-bearing-capacity mine tire and machining technology of steel wire inner ring machining machine

A technology of processing machinery and processing technology, which is applied in the field of steel wire inner ring processing, can solve the problems of bead traveler out of shape, affecting the pass rate of bead ring, and unable to shape the bead ring, so as to avoid the effect of out of shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

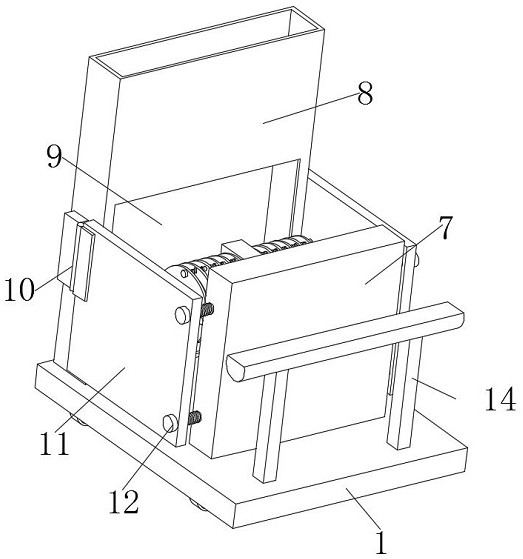

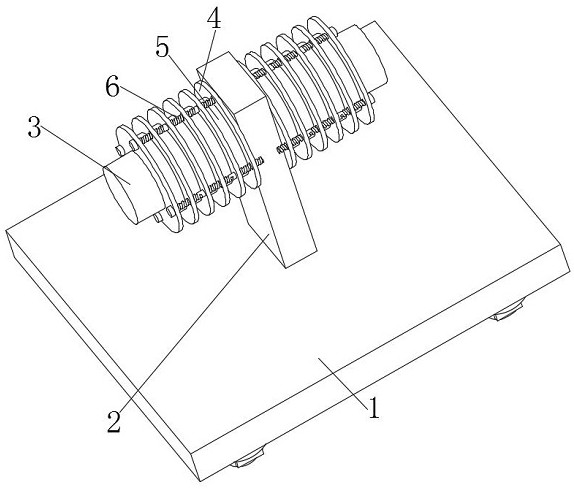

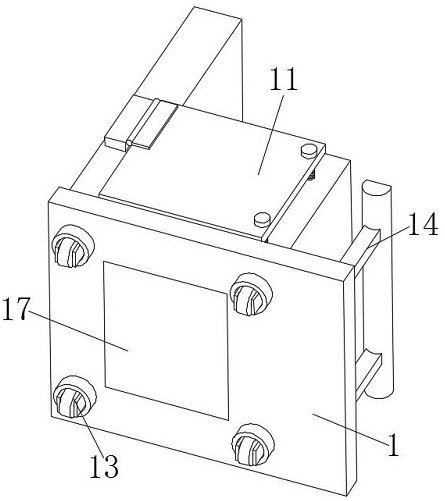

[0027] see Figure 1 to Figure 4 , the processing technology of the steel wire inner ring processing machine for high load-bearing mine tires that the present invention relates to, the process steps are:

[0028] Step 1: Cleaning: First, soak the steel wire in gasoline, dry it with compressed air, use lye to carry out electrolytic alkaline cleaning on the steel wire, then carry out chemical pickling on the steel wire, and then carry out ultrasonic water washing on the steel wire;

[0029] Step 2: Drawing: use the reel to connect the steel wire, and draw it through the wire drawing die, the total compression ratio of drawing is 20%-30%;

[0030] Step 3: heat treatment: heat-treat the steel wire so that the steel wire passes through the open flame furnace, the temperature of the open flame furnace is set at 1000-1100°C, the steel wire comes out of the open flame furnace and enters the lead tank for cooling, the lead quenching temperature is set at 550-600°C, and the steel wire i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com