Fly ash sorting system and method

A sorting system and technology for fly ash, which are applied in chemical instruments and methods, solid separation, and separation of solids from solids by air flow, can solve the problems of poor fly ash sorting effect, etc. Separation efficiency, the effect of solving unstable system operation and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

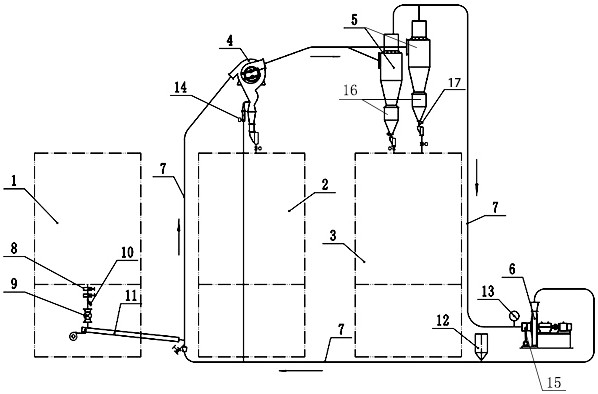

[0026] refer to figure 1 , a sorting system for fly ash, comprising a raw ash storehouse 1, a coarse ash storehouse 2 and a fine ash storehouse 3, the former ash storehouse 1 is connected to the main pipeline 7 of the system through a discharge mechanism, and the main pipeline 7 of the system is sequentially Connect the sorting mechanism and the centrifugal fan 6, and form a cycle, the sorting mechanism is connected with the coarse ash storehouse 2 and the fine ash storehouse 3 respectively, and the coarse ash collected by the sorting mechanism is sent into the coarse ash storehouse 2, and the sorting mechanism will The collected fine ash is sent into the fine ash storehouse 3.

[0027] Further, in this embodiment, the discharge mechanism includes a feed pipe and an air chute 11, the feed pipe is connected to the air chute 11, and the air chute 11 is connected to the system main pipe 7 , Fly ash (raw ash) can be transported into the main pipeline 7 of the system through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com