Chain plate filtering type solid-liquid separation device

A solid-liquid separation and filtration technology, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., to achieve the effect of taking into account efficiency, simple and reliable structure, and taking into account the removal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

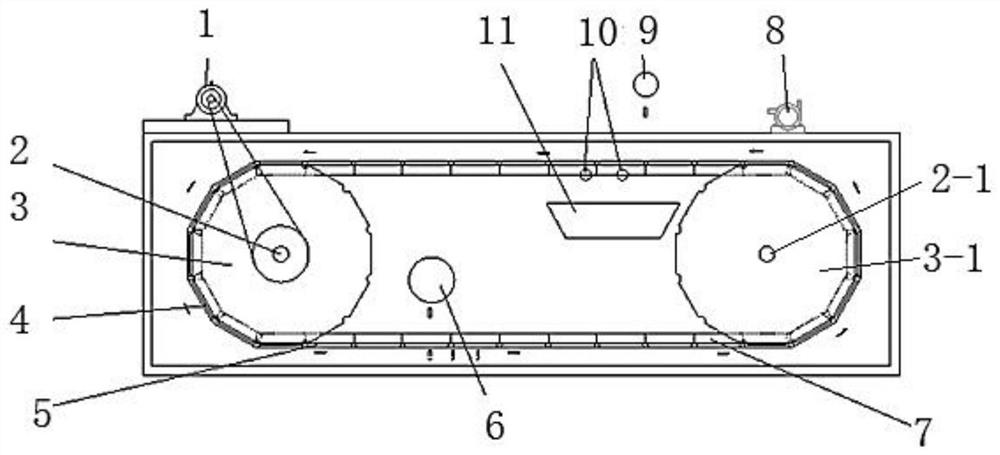

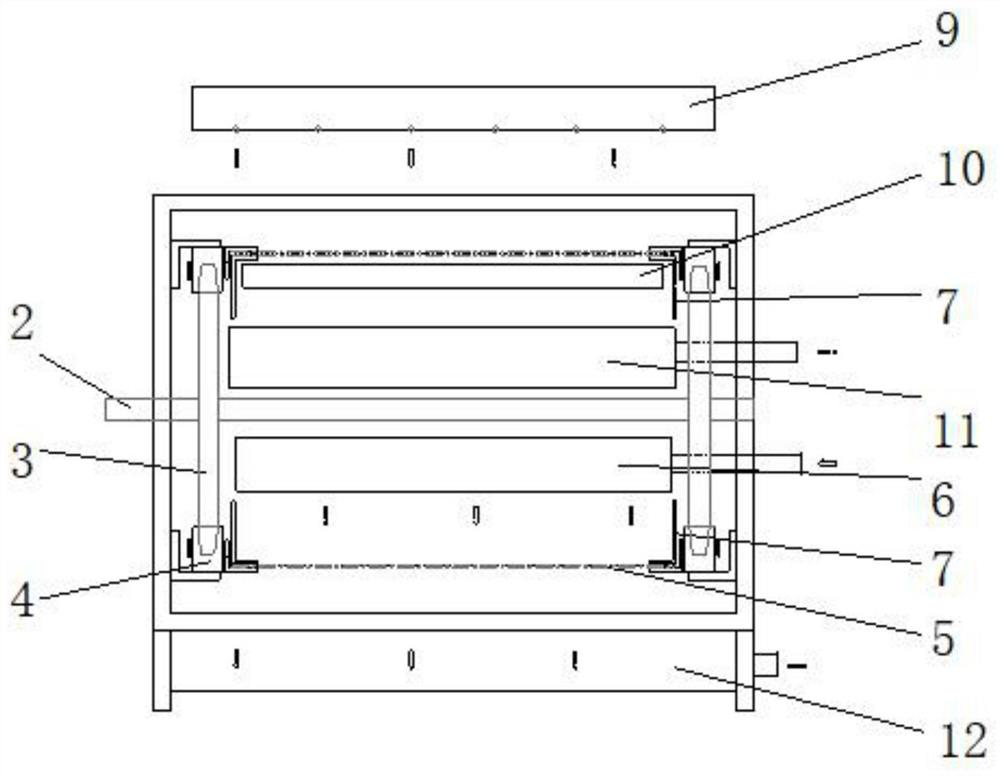

Embodiment 1

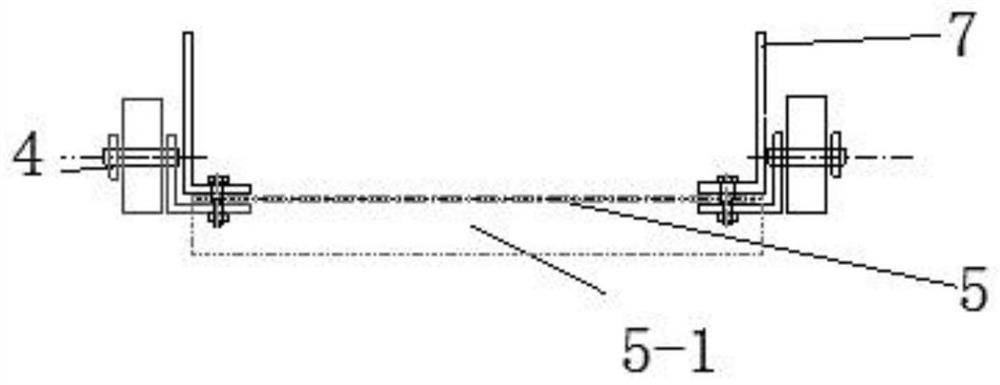

[0056] Embodiment 1: the fixed structure of the chain and the filter screen chain plate is that the length of each joint or N joints of the chain is the same as the two ends of the rectangular frame (width): Simultaneously, sprocket wheel is the structure of regular polygon, and the length of each side is equal to the length of every joint of chain, and sprocket wheel can be more than 6 sides when being regular polygon, and a pair of driving sprocket wheels 3 and a pair of passive sprocket wheels 3-1 should complete The same, including structure and size, wheel base (equal to the length of the rectangular frame 5-1), then the driving sprocket 3 engages and drives two parallel chains 4, and the chains drive the rectangular chain plate filter screen of the main body of the conveyor belt to rotate and successively undertake filtering Task, when running to the contact position of the scraping wheel 10, the bristles, fabric or rubber protrusions of the scraping wheel 10 scrape the f...

Embodiment

[0057]Embodiment: driving sprocket 3 and driven sprocket 3-1 are regular octagons, and each limit is provided with side teeth 3-2 and meshes with every joint chain, and the length of every joint chain is the width of filter screen chain plate frame can be is 20 cm. It can also be any polygon of 9-25, and the number of sides means the increase of the diameter of the sprocket. The use of circular sprockets is also a feasible solution, but the frame of the rectangular chain plate filter is a rigid structure, and the strength of the frame is high. When the two ends of the frame are relatively fixed with the chain, it is necessary to install a chain that deforms when it is coiled on the sprocket. The two ends of the frame and the chain The fixed structure of each chain and the two ends of the filter screen chain plate frame is directly connected to the chain through two fixed pins, but there must be a pin slot when deformed, so that the pin slides in the pin slot, or The chain fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com