A self-supporting material with one-dimensional and two-dimensional hybrid structure for positive electrode of lithium-air battery and preparation method thereof

A self-supporting, hybrid technology, applied in fuel cell half-cells and secondary battery half-cells, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problem that the catalytic activity is difficult to be fully utilized , It is difficult to obtain high capacity performance and other problems, to achieve excellent electrocatalytic activity, solve the effect of catalyst agglomeration, and increase the surface area of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

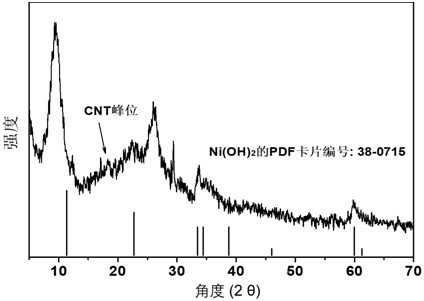

Image

Examples

Embodiment 1

[0033] In this embodiment, a self-supporting material with a one-dimensional and two-dimensional hybrid structure for the positive electrode of a lithium-air battery and a preparation method thereof include the following steps:

[0034] (1) Soak the bulk carbon nanotube sponge in absolute ethanol solution for 2 min for hydrophilic treatment.

[0035] (2) Prepare the dispersion. Add 3.2 mmol of nickel nitrate, 14 mmol of urea, 0.77 mmol of ammonium fluoride, and 1 mmol of sodium chromate into a 40 mL Teflon reactor in sequence, and stir for 2 h to obtain a uniformly dispersed dispersion.

[0036] (3) Take the carbon nanotube sponge after hydrophilic treatment (1 cm×1 cm×3 mm), immerse it in the dispersion prepared in step (2), place it on a shaker and vibrate for 4 h, so that the dispersion completely infiltrates the sponge.

[0037] (4) Transfer the sponge-impregnated dispersion in step (3) to a 100 mL reactor for solvothermal reaction. The reaction condition is to keep warm ...

Embodiment 2

[0042] In this embodiment, a self-supporting material with a one-dimensional and two-dimensional hybrid structure for the positive electrode of a lithium-air battery and a preparation method thereof include the following steps:

[0043] (1) Soak the bulk carbon nanotube sponge in absolute ethanol solution for 2 min for hydrophilic treatment.

[0044] (2) Prepare the dispersion. Add 3.2 mmol of nickel nitrate, 14 mmol of urea, 0.77 mmol of ammonium fluoride, and 1 mmol of sodium tungstate into a 40 mL Teflon reactor in sequence, and stir for 2 h to obtain a uniformly dispersed dispersion.

[0045] (3) Take the carbon nanotube sponge after hydrophilic treatment (1 cm × 1 cm × 3 mm), immerse it in the dispersion prepared in step (2), place it on a shaker and vibrate for 4 h to make the dispersion completely infiltrate the sponge.

[0046] (4) Transfer the sponge-impregnated dispersion in step (3) to a 100 mL reactor for solvothermal reaction. The reaction condition is to keep wa...

Embodiment 3

[0051] In this embodiment, a self-supporting material with a one-dimensional and two-dimensional hybrid structure for the positive electrode of a lithium-air battery and a preparation method thereof include the following steps:

[0052] (1) Soak the carbon nanotube sponge in absolute ethanol solution for 2 min for hydrophilic treatment.

[0053] (2) Prepare the dispersion. Add 2.4 mmol of nickel nitrate, 0.8 mmol of ferric nitrate, 14 mmol of urea, 0.77 mmol of ammonium fluoride, and 1 mmol of sodium chromate into a 40 mL Teflon reactor in sequence, and stir for 2 h to obtain a uniform Dispersed dispersion.

[0054] (3) Take the carbon nanotube sponge after hydrophilic treatment (1 cm × 1 cm × 3 mm), immerse it in the dispersion prepared in step (2), place it on a shaker and vibrate for 4 h to make the dispersion completely infiltrate the sponge.

[0055] (4) Transfer the first dispersion soaked in sponge in step (3) to a 100 mL reactor for solvothermal reaction. The reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com