Lobe ejection system with high infrared stealth characteristic

A wave lobe and infrared technology, applied in the field of ejection systems, can solve the problems of reducing the stealth performance of ships, reducing the wall surface of the exhaust pipe, etc., to achieve the effects of improving infrared stealth performance and survivability, increasing stability, and reducing high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

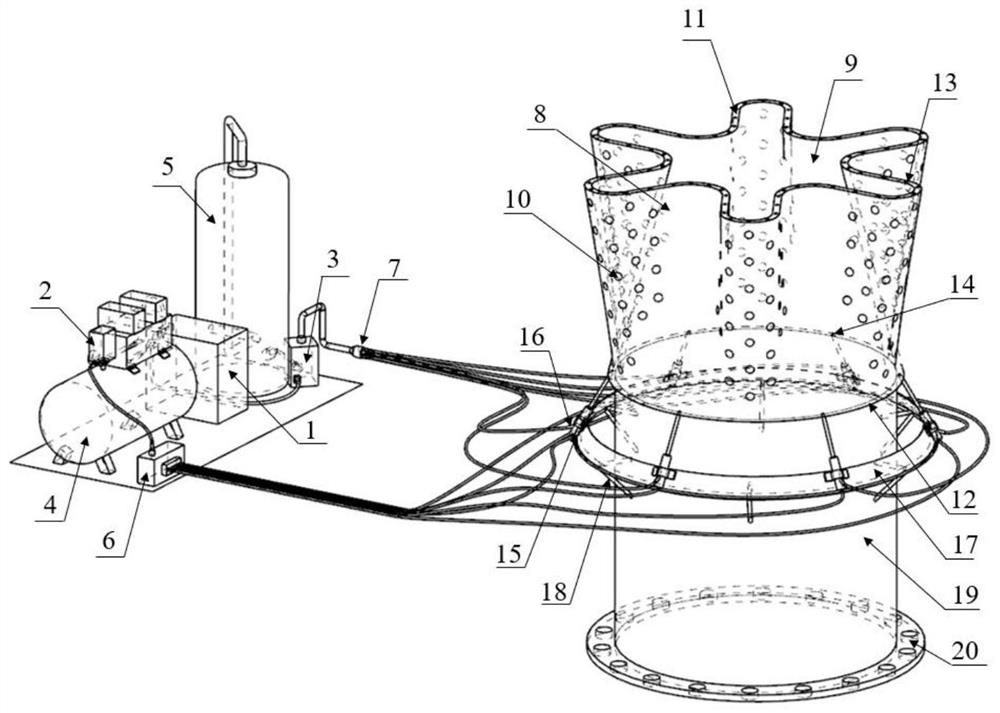

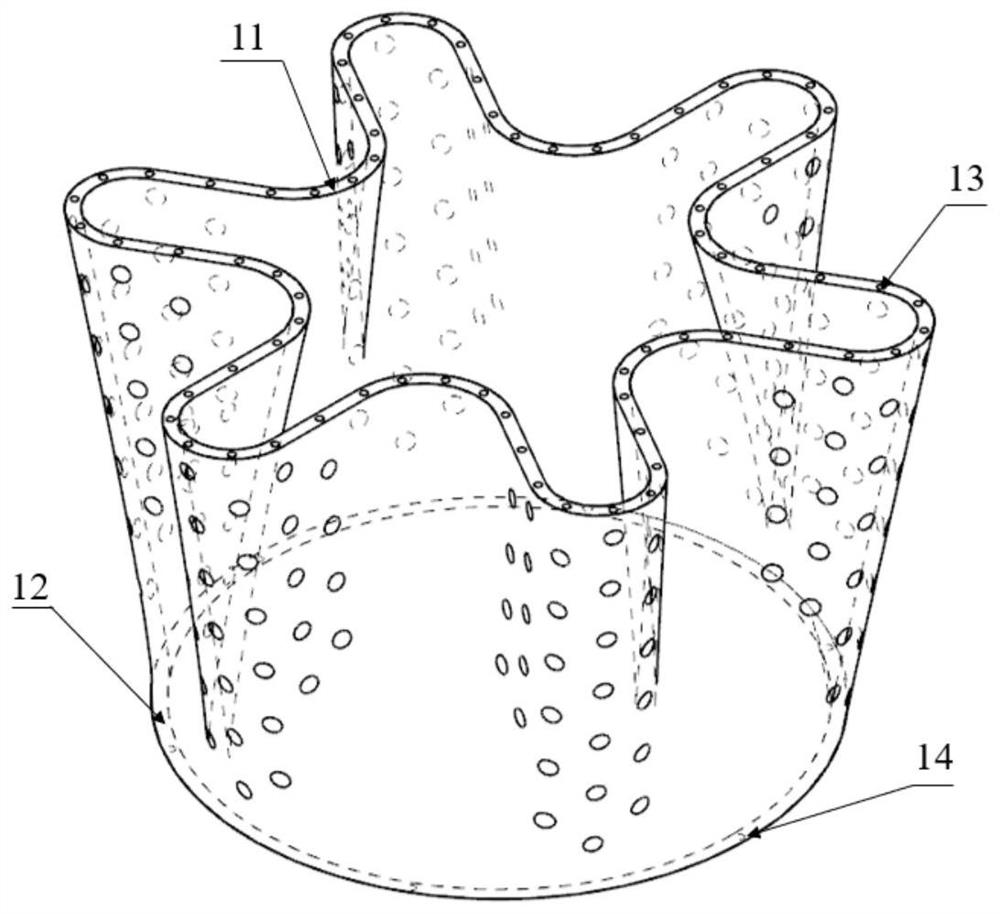

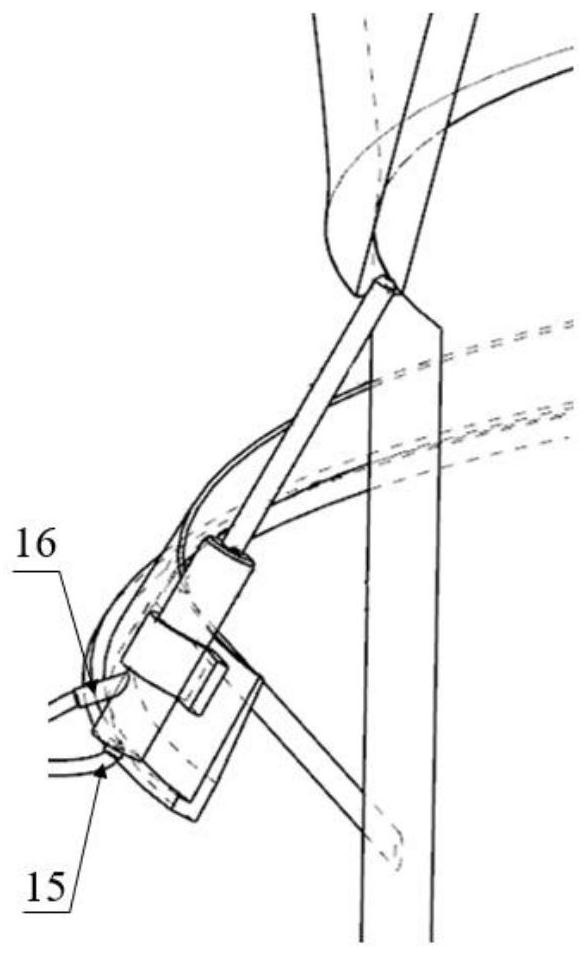

[0020] Such as Figure 1-4 As shown, the lobe ejection system with high infrared stealth characteristics in this embodiment includes a double-layer lobe ejector, a film cooling device, a spray cooling device, and a center console 1 . The film cooling device includes a first controller 2, an air storage tank 4, and a static pressure tank 6; the spray cooling device includes a second controller 3, a water storage tank 5, and a water separator 7; the double-layer lobe ejector includes an outer The wall surface 8, the inner wall surface 9, and the outer wall surface are provided with a through hole 10, a head gasket 11, a tail gasket 12, an exhaust hole 13 is opened on the head gasket, and an installation hole 14 is provided for the tail gasket; ejector An annular metal frame 17 is arranged on the outside, and the annular metal frame 17 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com