Device for simultaneously removing burrs at inner and outer orifices of cross hole

A technology of intersecting holes and orifices, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of changing mechanical properties, high labor intensity, low efficiency, etc., achieve high-speed and efficient removal, improve work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose of the invention of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

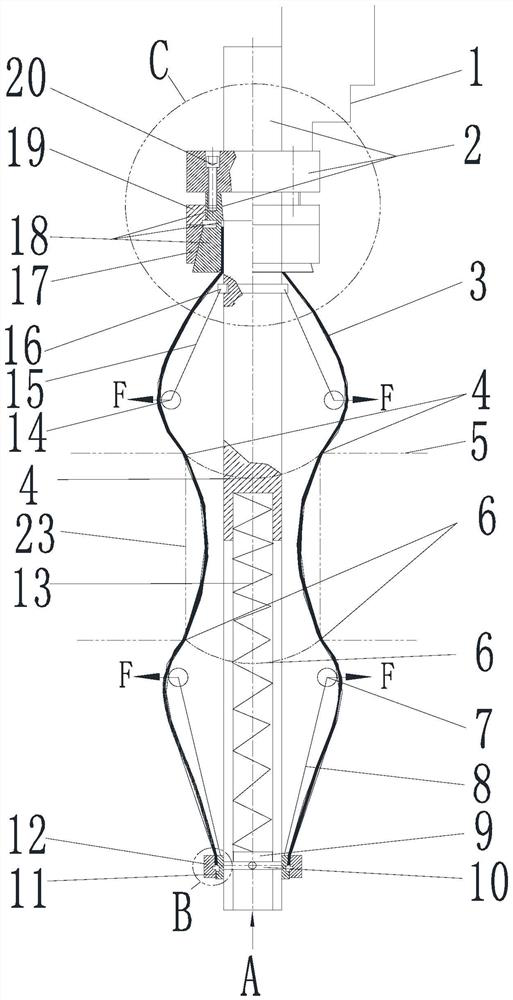

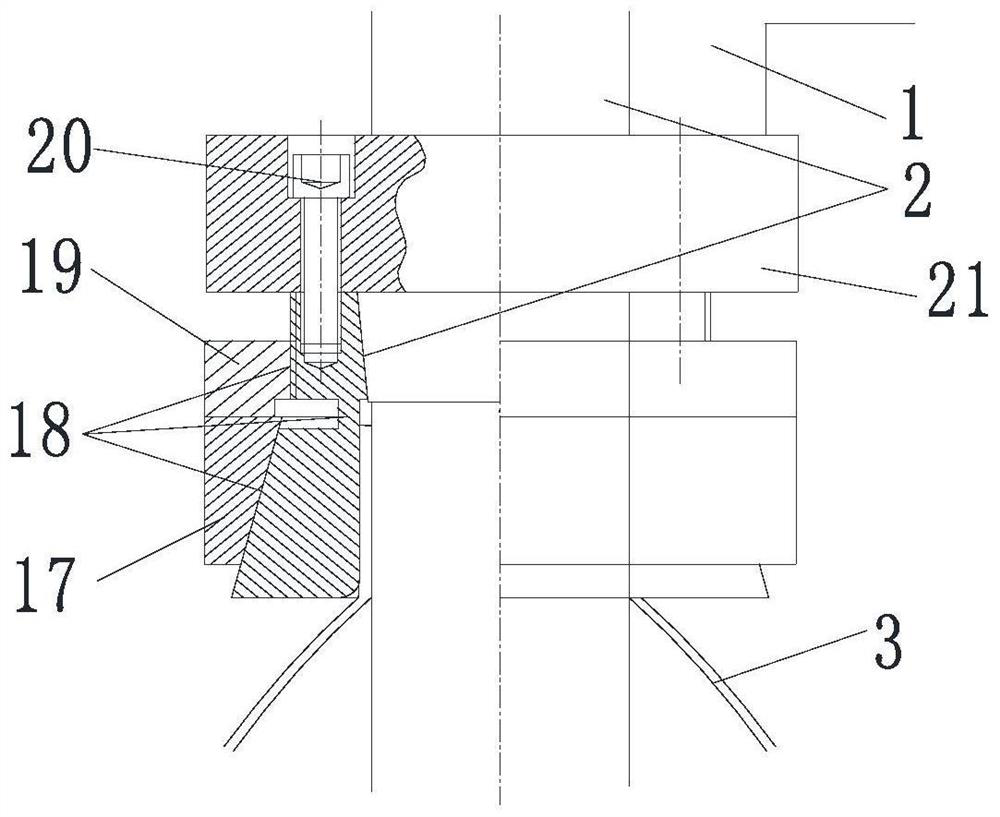

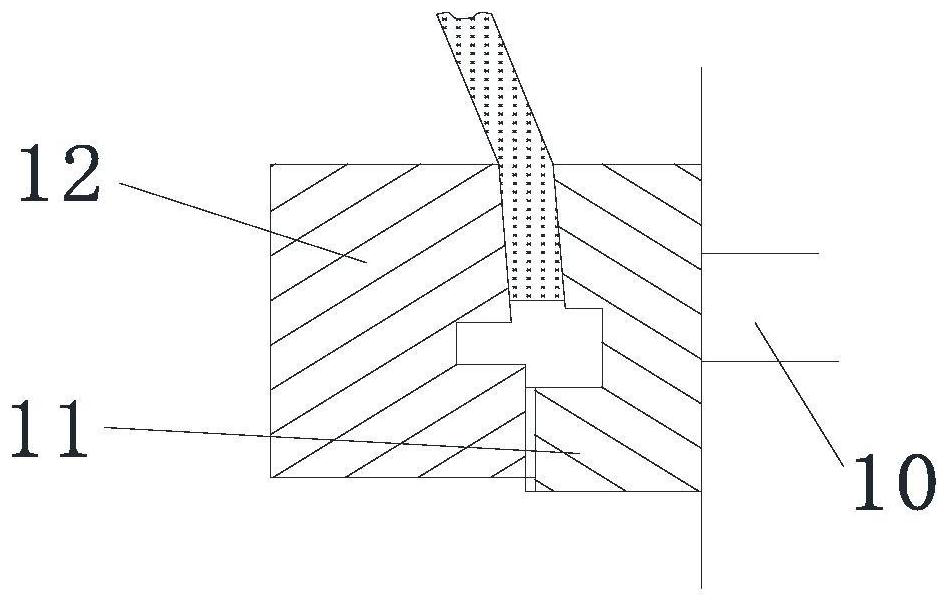

[0022] like figure 1 and 4 As shown, the device 24 for simultaneously removing burrs at the inner and outer openings of the intersecting holes includes a main shaft 2, a fixed abrasive belt clamping structure, a flexible abrasive belt 3, a movable abrasive belt clamping structure, a return spring 13, a first elastic support structure and a second elastic support structure. Two elastic supporting structures, one end of the main shaft 2 is provided with a boss portion 21, the lower part of the boss portion 21 is provided with a card slot, and the other end of the main shaft 2 is provided with a cross groove. The return spring 13 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com