Tracer agent putting device for oil and gas field and operation method

A technology for injecting devices and tracers, applied in the field of oil and gas fields, can solve the problems of uneven penetration of tracers, inaccurate data analysis, stratification or uneven concentration, etc., and achieve consistent concentration, accurate data analysis, and uniform penetration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

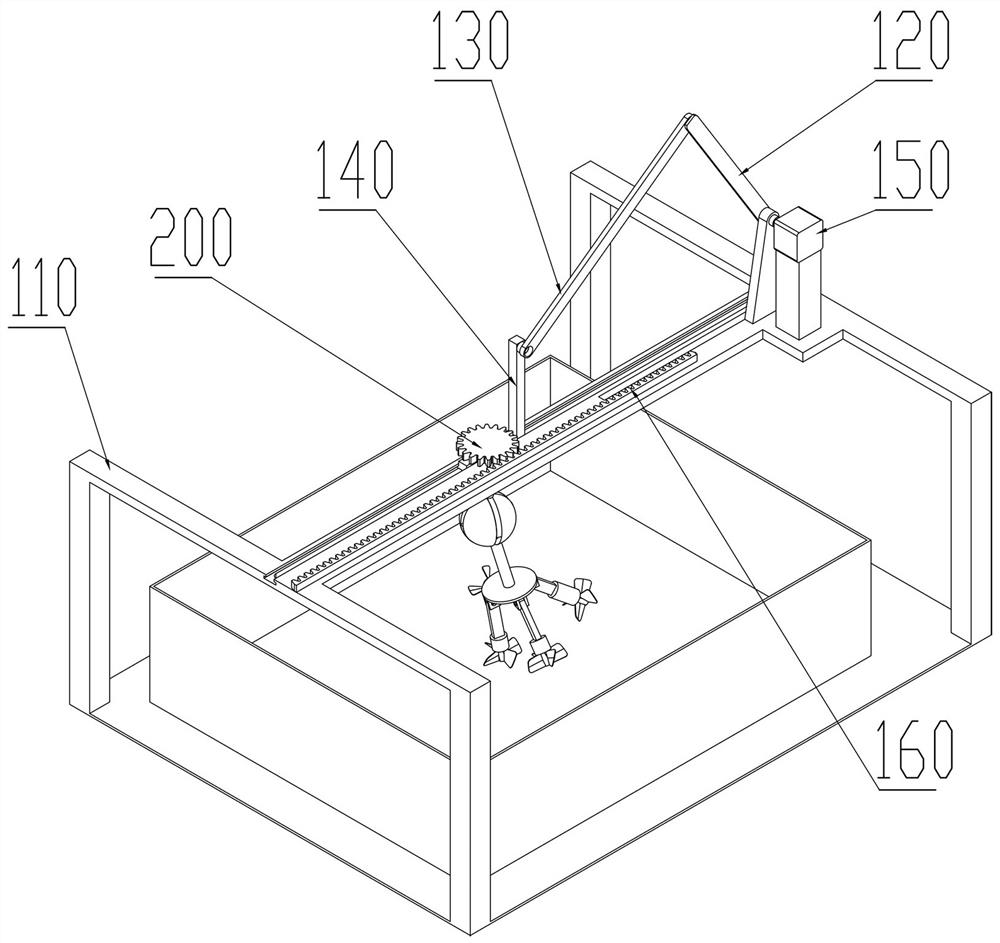

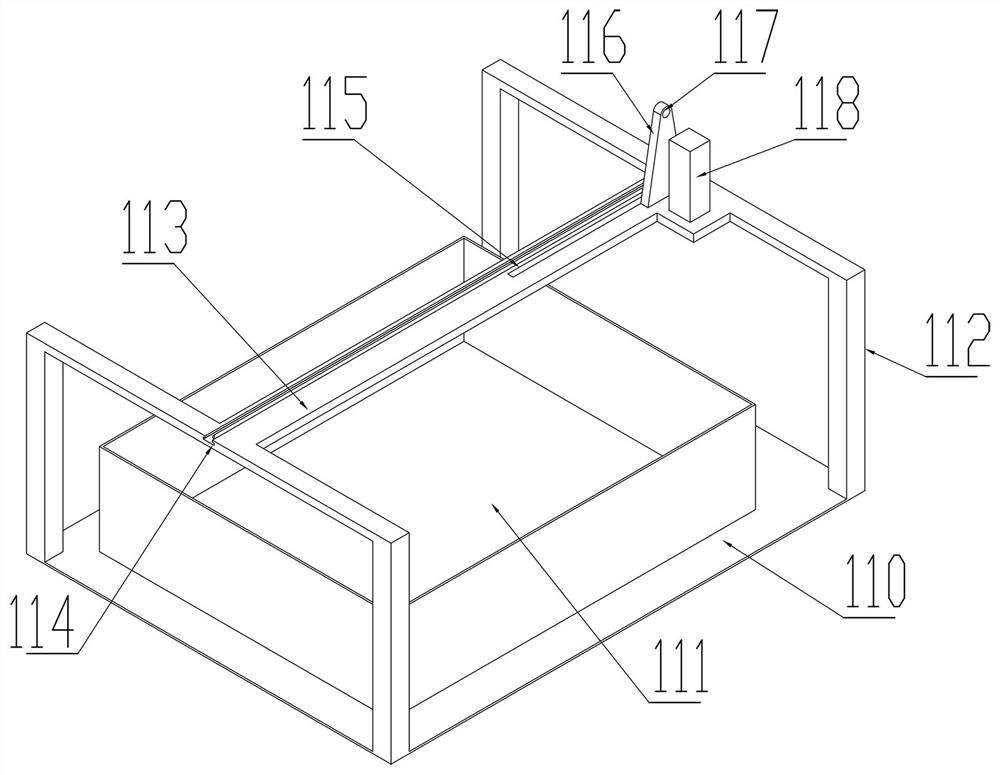

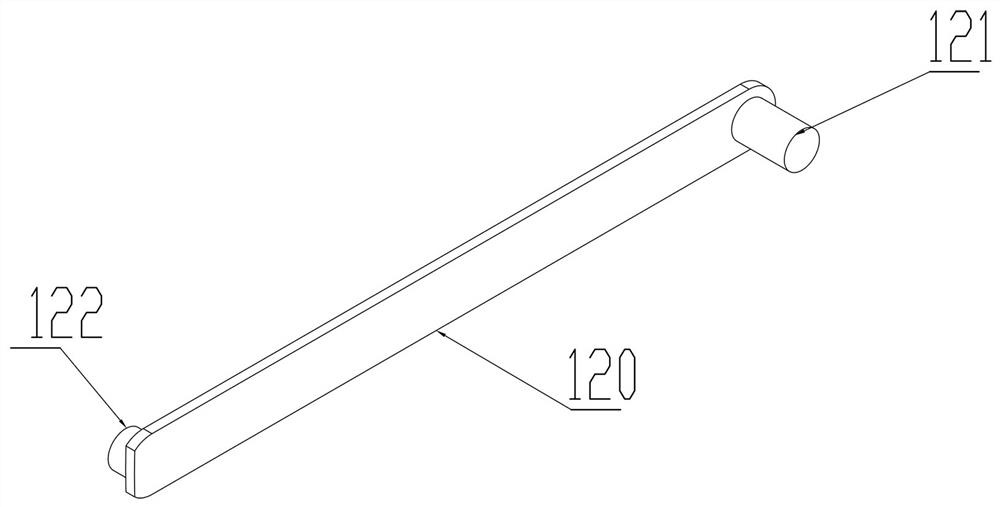

[0024] A tracer injection device for oil and gas fields, including a frame 110, a driving rod 120, an intermediate rod 130, a slider 140, and a stirring device 200, and the stirring device 200 includes a gear 210, a ball head 220, a joint 230, and a No. 1 swing rod 240 , No. 2 pendulum 250, stirring wheel 260, the upper part of the frame 110 has a dosing pool 111, the left and right sides of the frame 110 have two support frames 112 symmetrically arranged, and an intermediate plate 113 is arranged between the two support frames 112 There is a chute 114 in the middle of the middle plate 113, an avoidance groove 115 is provided on the right side of the middle plate 113, a support plate 116 is provided on the front part of the right side of the middle plate 113, a support plate hole 117 is provided on the upper part of the support plate 116, and a motor plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com