Multifunctional down filling workbench in garment production and down filling steps thereof

A workbench and multi-functional technology, applied in the field of clothing production, can solve problems such as failure to meet normal production needs, simple structure and function, etc., to achieve the effects of ensuring fluency, improving production quality, and realizing semi-automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

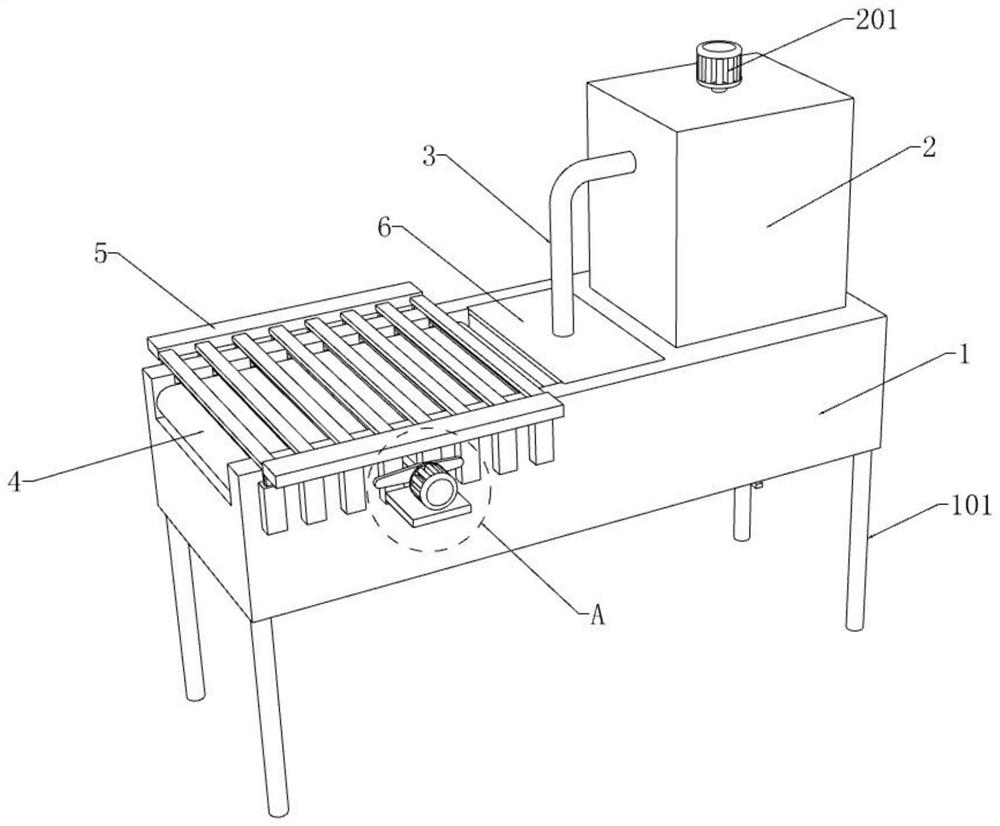

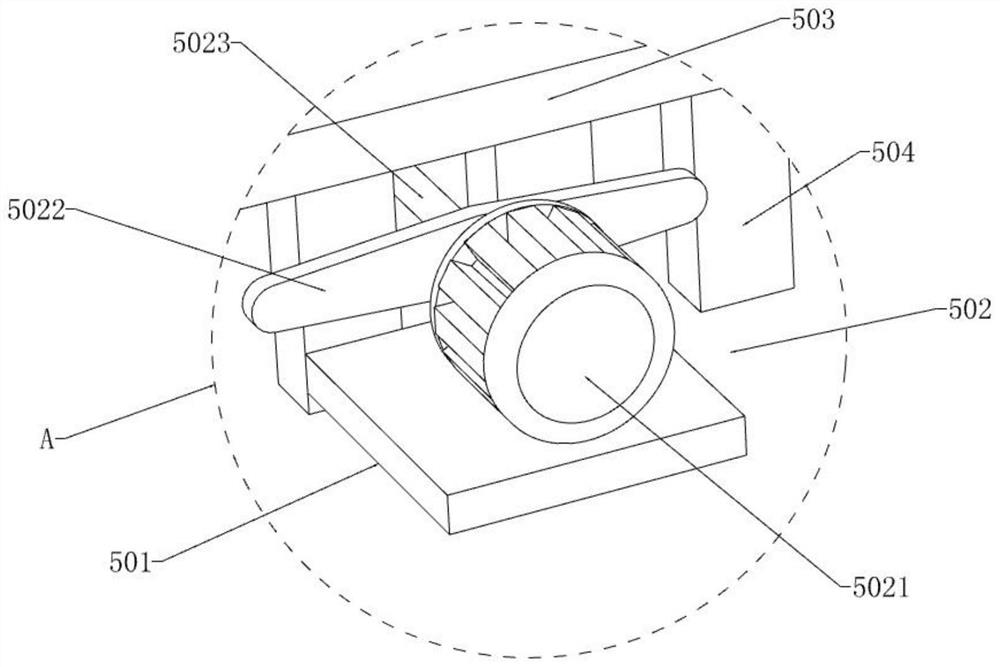

[0036] refer to Figure 1-3 , Figure 5 and Image 6 , a multi-functional cashmere-filling workbench in garment production, comprising a workbench 1 with support legs 101 installed at the four corners of the bottom end, a mounting groove and a weighing groove 8 are provided on the top of the workbench 1, and a mounting groove is installed in the mounting groove Conveyor belt 4, workbench 1 is positioned at conveyer belt 4 place and is equipped with velvet mechanism 5;

[0037] The bottom inner wall of the weighing tank 8 is equipped with a load cell, and the top of the weighing tank 8 is equipped with a matching transparent observation cover plate 6, and the side wall of the workbench 1 is equipped with a controller, and the input terminal of the controller is connected to the The weighing sensor is electrically connected, and the output end of the controller is electrically connected with the driving motor on the conveyor belt 4. The model of the controller is DATA-7311.

...

Embodiment 2

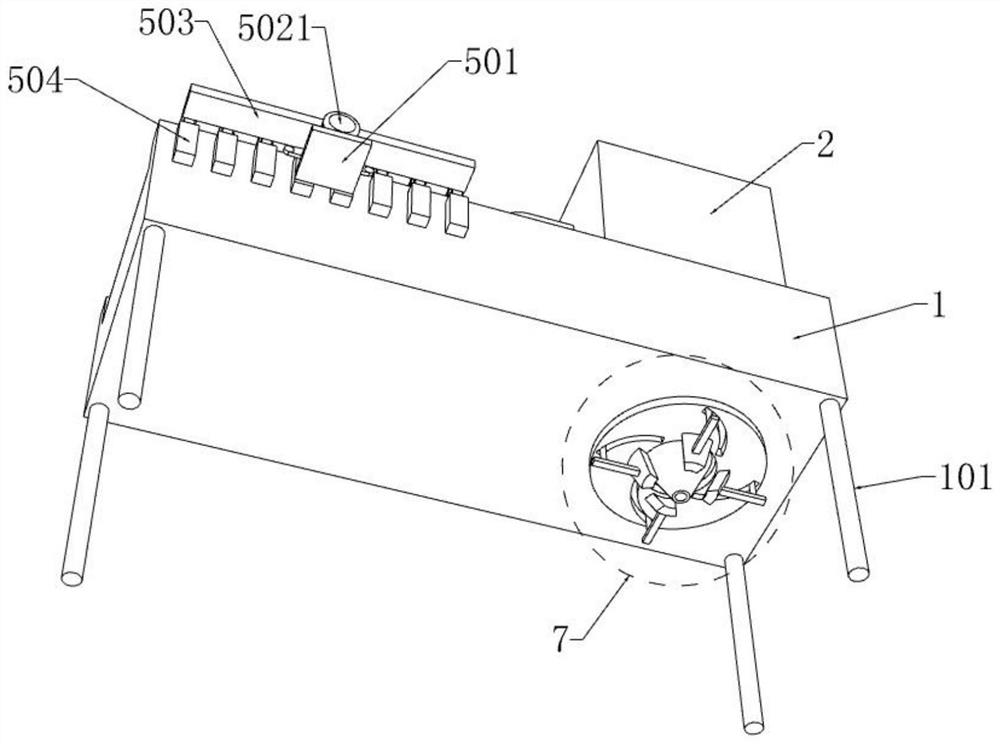

[0045] refer to image 3 and Figure 4 , a multifunctional down filling workbench in garment production, the bottom end of the workbench 1 is provided with a down filling mechanism 7, and the down filling mechanism 7 is located directly below the down filling box 2, and the down filling mechanism 7 includes a down filling head 701 , rotating disc 702, movable plate 703, splint 704, movable rod 705 and limit groove 706, the bottom end of workbench 1 is fixedly installed with the pile filling head 701 that is communicated with the chute, and the bottom end of workbench 1 is rotated and installed There is a rotating disk 702, and the pile filling head 701 is located inside the rotating disk 702. The bottom end of the workbench 1 is slidably installed with movable rods 705 distributed in a circular array, and the bottom end of the movable rods 705 runs through the rotating disk 702 and is fixedly connected with a movable plate. 703, the end of the movable plate 703 close to the p...

Embodiment 3

[0048] A down filling step of a multifunctional down filling workbench in garment production, comprising the following steps: firstly setting the down filling amount to be filled through a controller, and then putting the down jacket interlayer to be filled on the down filling head 701 , and through the adjustment of the down filling mechanism 7, the splint 704 cooperates with the down filling head 701 to clamp the down jacket interlayer to be filled (see embodiment two for specific implementation), and starts the motor on the conveyor belt 4 and the drive motor 5021 , high-pressure blower and stirring motor 201, and then spread the eiderdown to be filled as evenly as possible on the surface of the conveying belt 4. Feather is beat (concrete down velvet mode sees embodiment one), and the feather after beating softness is imported into weighing tank 8 inside and is weighed by load cell, when the numerical value that load cell weighs reaches controller setting When the filling v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com