Electric heating device and method for producing same

A technology of electric heating devices and heating chambers, applied in the direction of electric heating devices, immersion heating devices, ohmic resistance heating, etc., can solve safety problems and other problems, and achieve the effects of compact structure, good dimensional stability, and firm fluid-tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

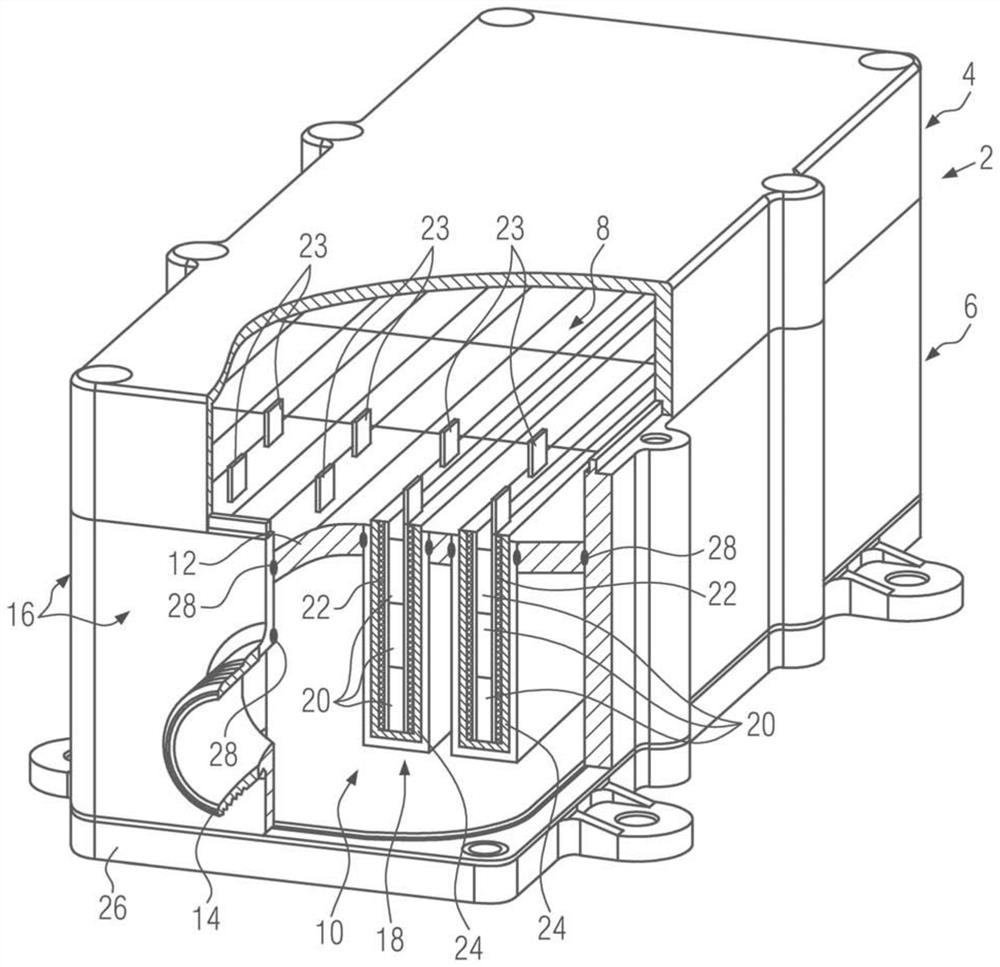

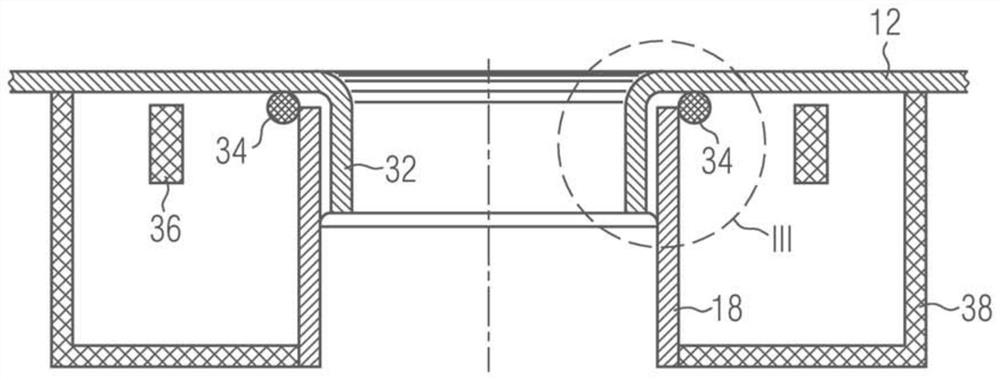

[0029] In the figures, reference numeral 2 designates a housing with a housing upper part 4 and a housing lower part 6 . The housing upper part 4 surrounds the connection chamber 8 . The housing lower part 6 surrounds the heating chamber 10 . A partition wall 12 is located between the heating chamber 10 and the connection chamber 8 . The partition wall 12 is fluid-tight so that the liquid fluid to be heated contained in the heating chamber 10 cannot reach the connection chamber 8 . At the level of the heating chamber 10 , the housing 2 stands above via a connection port 14 for connecting fluid-conducting lines within the motor vehicle. These connection ports 14 protrude from an opposite housing wall 16 which in the present example surrounds the heating chamber 6 in the circumferential direction. In this figure, only one of these connection ports 14 is visible, ie partially cut away.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com