Under-screen fingerprint tester

A tester and fingerprint technology, applied in telephone communication, electrical components, branch office equipment, etc., can solve problems such as difficult to estimate the weight of the required weight, occupy warehouse space, and increase the weight of the module, so as to reduce the debugging time, The effect of improving product precision and simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

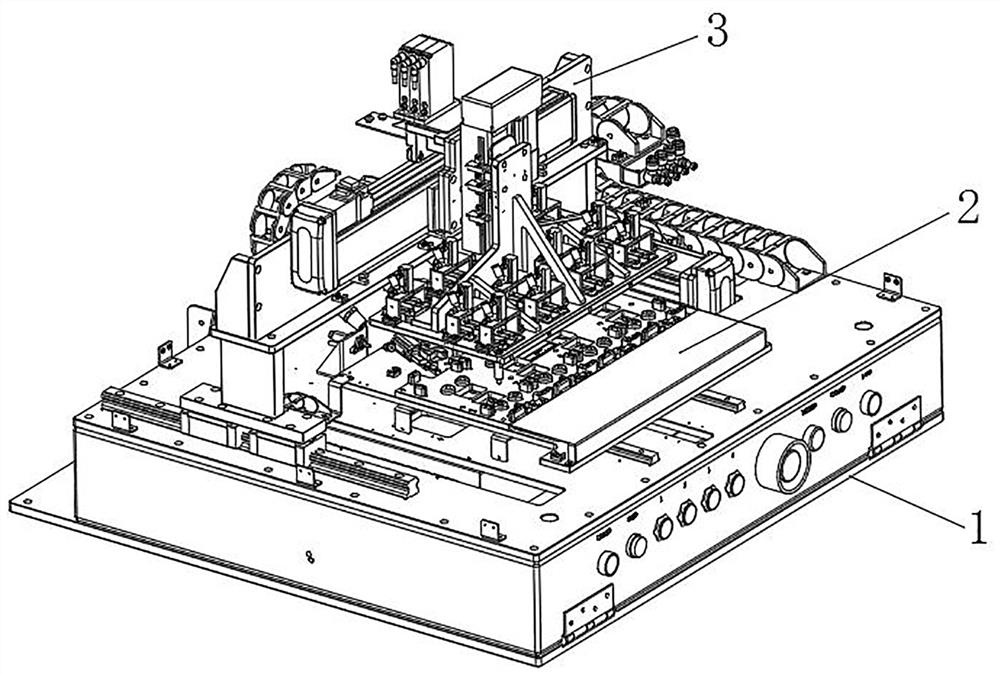

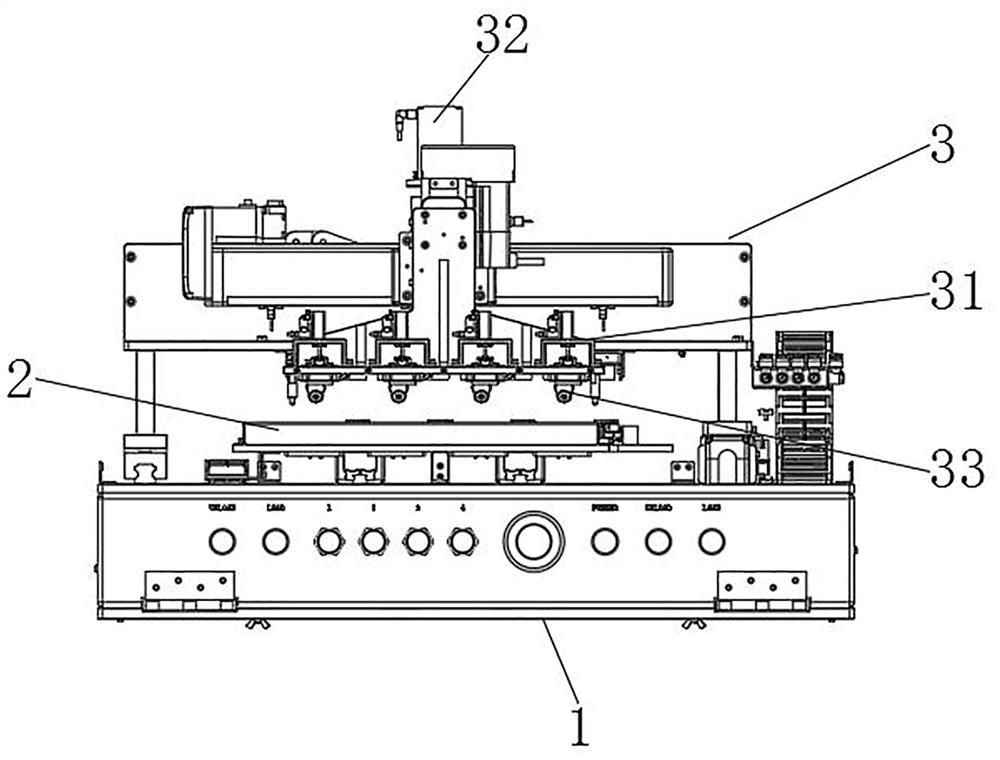

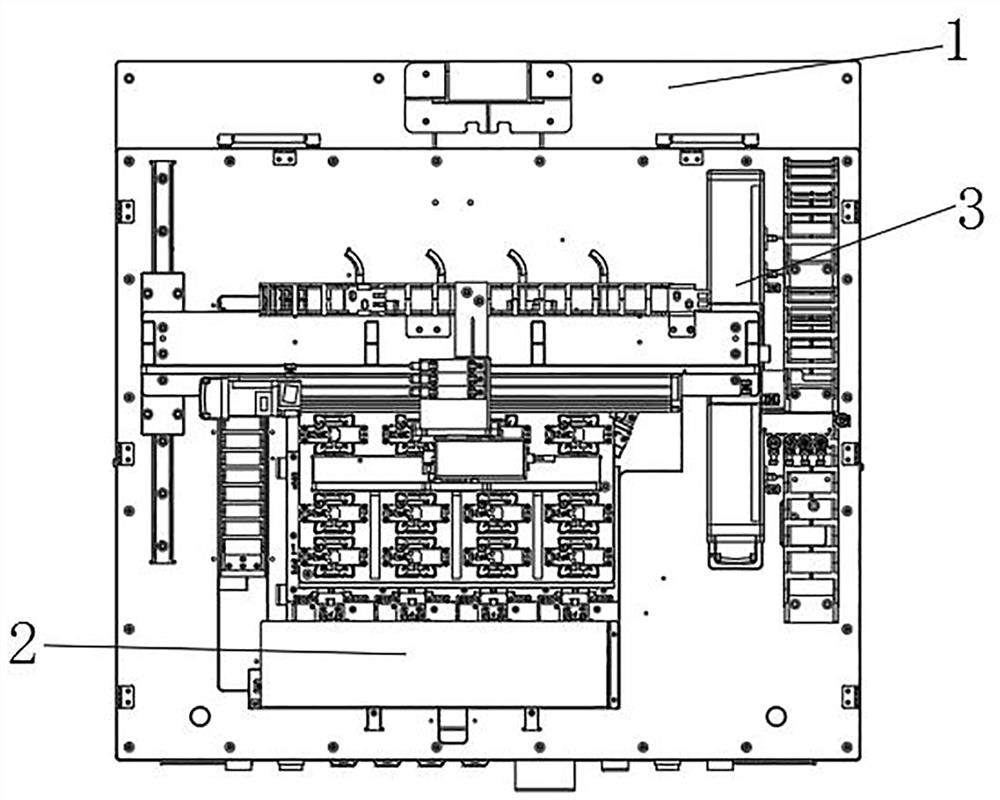

[0028] The embodiment of the present invention discloses an under-screen fingerprint tester, such as Figure 1-9 shown, including:

[0029] Test bench 1, the top of the test bench 1 is provided with a mobile phone tray 2 and a pressure control mechanism 3;

[0030] The fingerprint tester is composed of a test bench 1, a mobile phone tray 2 and a pressure control mechanism 3.

[0031] The mobile phone tray 2, the mobile phone tray 2 includes a tray bottom plate 21, one side of the top of the tray bottom plate 21 is provided with a USB plug-in module 23, and the other side of the top of the tray bottom plate 21 is provided with a mobile phone clamping and positioning mechanism 25, and a mobile phone clamping and positioning mechanism 25 One side thereof and one side of the USB plug-in module 23 are provided with a mobile phone carrier board 24;

[0032] Wherein the mobile phone carrier board 24 can load four mobile phones at the same time, the mobile phone clamping and positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com