Processing device and processing method of Chinese zither panel

A processing device and Guzheng technology, applied to instruments, stringed instruments, harps, etc., can solve the problems of Guzheng panel production difficulty, production cost, and processing time reduction, and achieve the effect of solving production difficulty and production cost, and reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

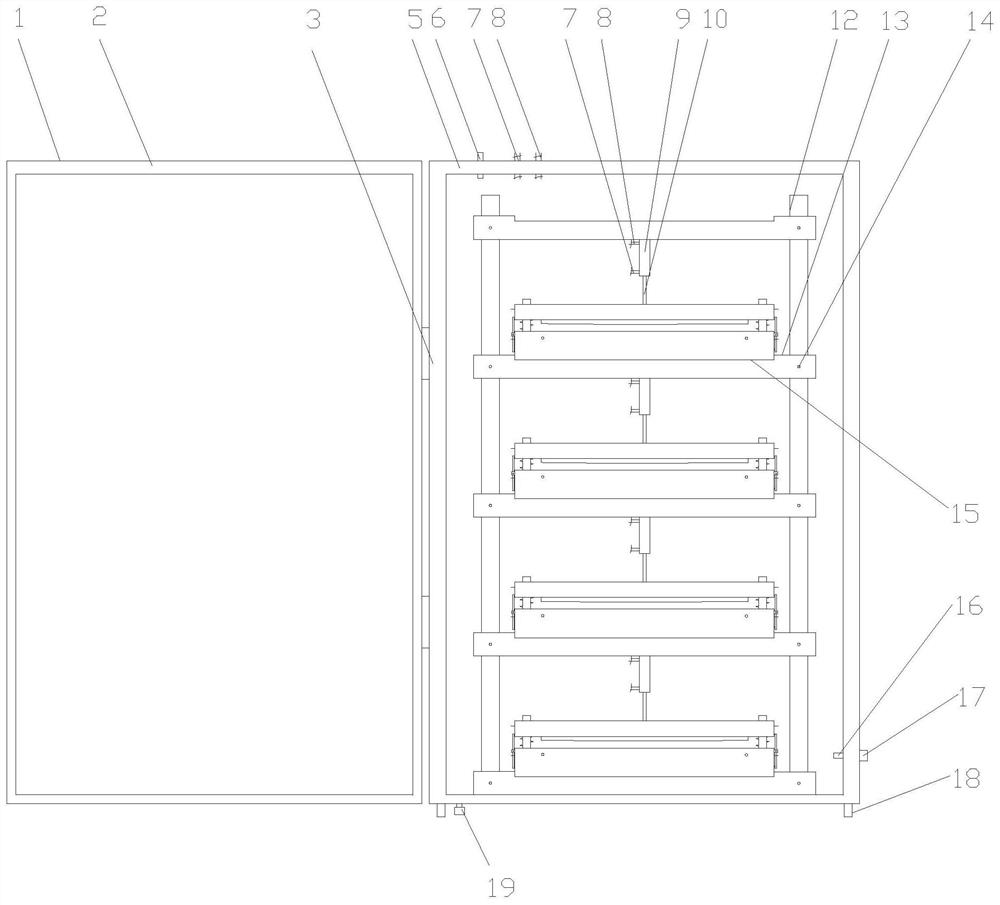

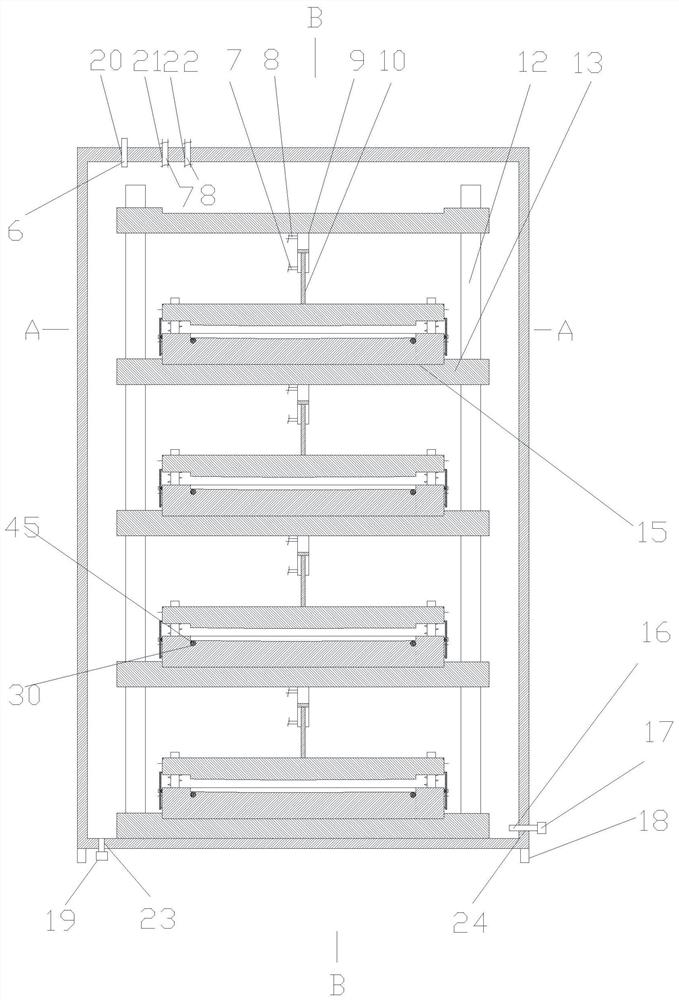

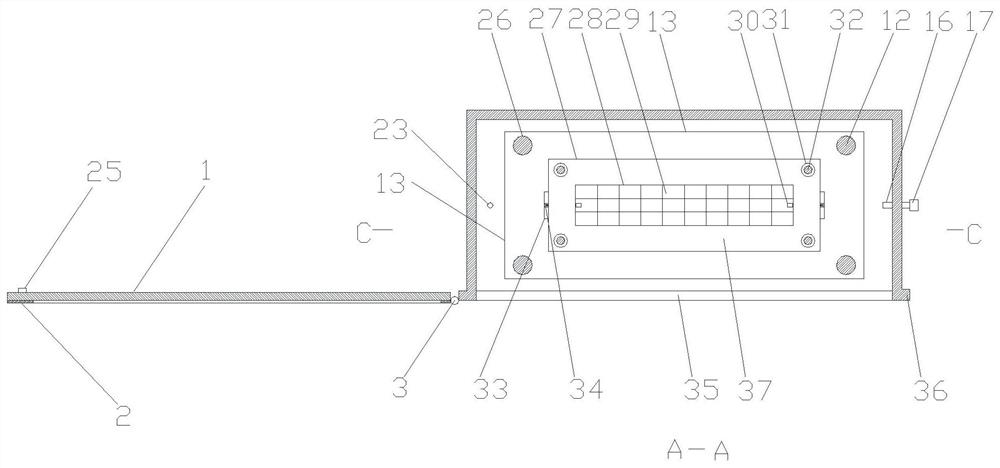

[0029] Such as Figure 1 to Figure 9 As shown, a processing device for a guzheng panel is composed of a sealed door 1, a hinge 3, a main compartment 5, a pressure reducing valve 6, a first oil delivery pipe 7, a second oil delivery pipe 8, a hydraulic cylinder 9, a support rod 12, and a fixed support plate 13 , Steam pipeline 16, valve 17, drain valve 19, molding mechanism 27 are formed.

[0030] Specifically, the main compartment 5 is a cuboid box, the top of the main compartment 5 is provided with a round through hole 20 for placing the pressure reducing valve 6, a round through hole 21 for placing the first oil delivery pipe 7, and a round through hole 22 for placing the second oil delivery pipe 7; The bottom on the right side is provided with a circular through hole 24 for placing a steam pipeline 16, and the steam pipeline 16 is also connected with a valve 17 out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com