Bulk material loading uniform material distribution self-adaptive adjusting method

A technology of self-adaptive adjustment and uniform distribution, applied in loading/unloading, transportation and packaging, data processing applications, etc., can solve the problems of increased operation defects and high workload of operators, so as to improve loading efficiency and simplify labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

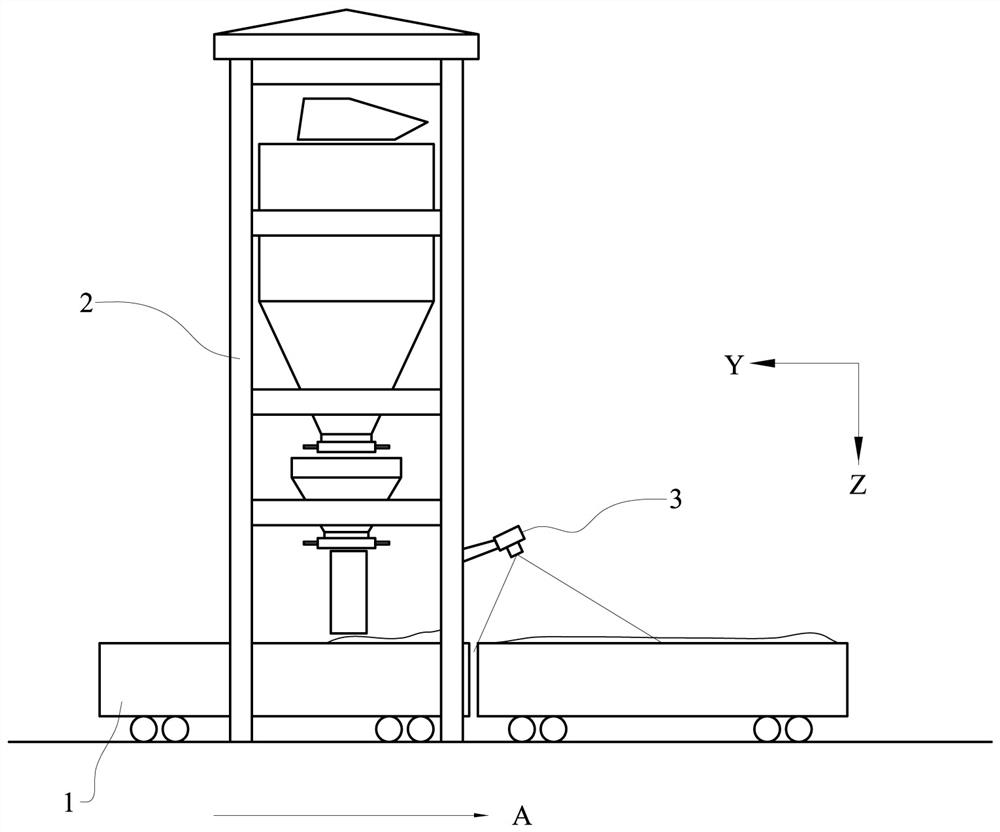

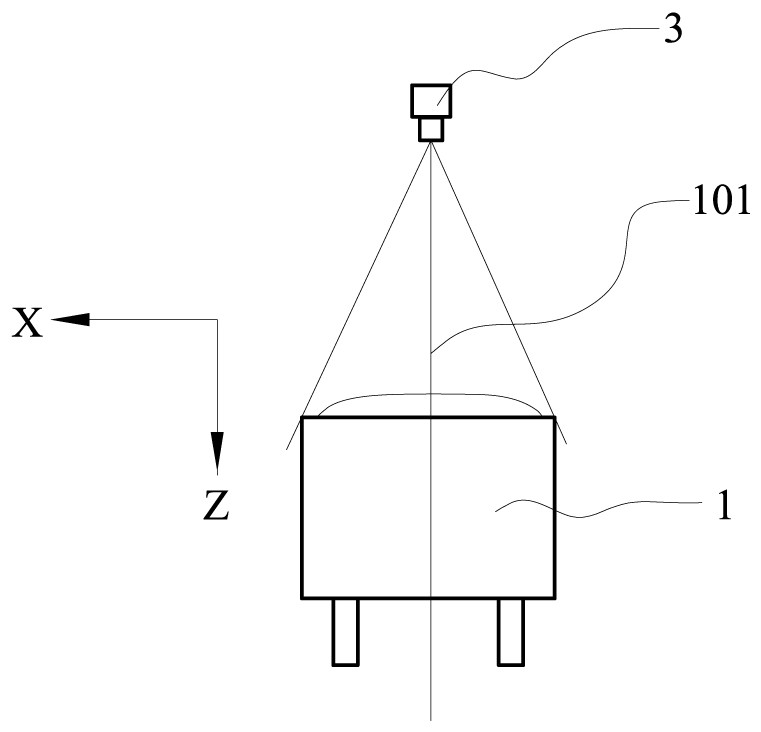

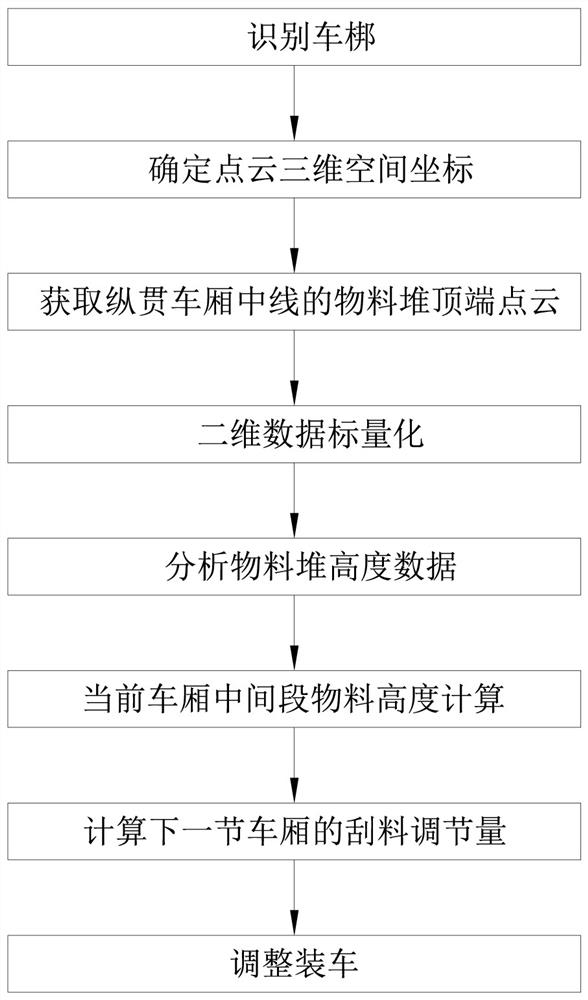

[0029] This embodiment is an adaptive adjustment method for uniform distribution of bulk material loading. The system used in the method includes: along the running direction of the train 1 ( figure 1 The direction of the middle arrow A), in the exit direction of the loading port 2 of the loading station, facing the longitudinal center line 101 of the carriage (see figure 2 ) at least one multi-line lidar 3 is set up above, and the number and height of the lidar are determined based on the ability to scan the entire carriage range, such as figure 1 , 2 shown.

[0030] The loading station described in this embodiment is a special quantitative loading station for railway bulk goods. This loading station usually spans the railway line, and the train passes through the bottom of the loading station. The loading station is usually provided with a buffer bin and a gate with discharging materials. Quantitative bins and chutes, this embodiment only focuses on the gates and chutes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com