Protective cover for heat insulation and heat preservation of extrusion die head

A technology of thermal insulation and extrusion die, which is used in spinneret assemblies, textiles and papermaking, etc., and can solve the problems of easily broken filaments, uneven discharge, and large contact temperature difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

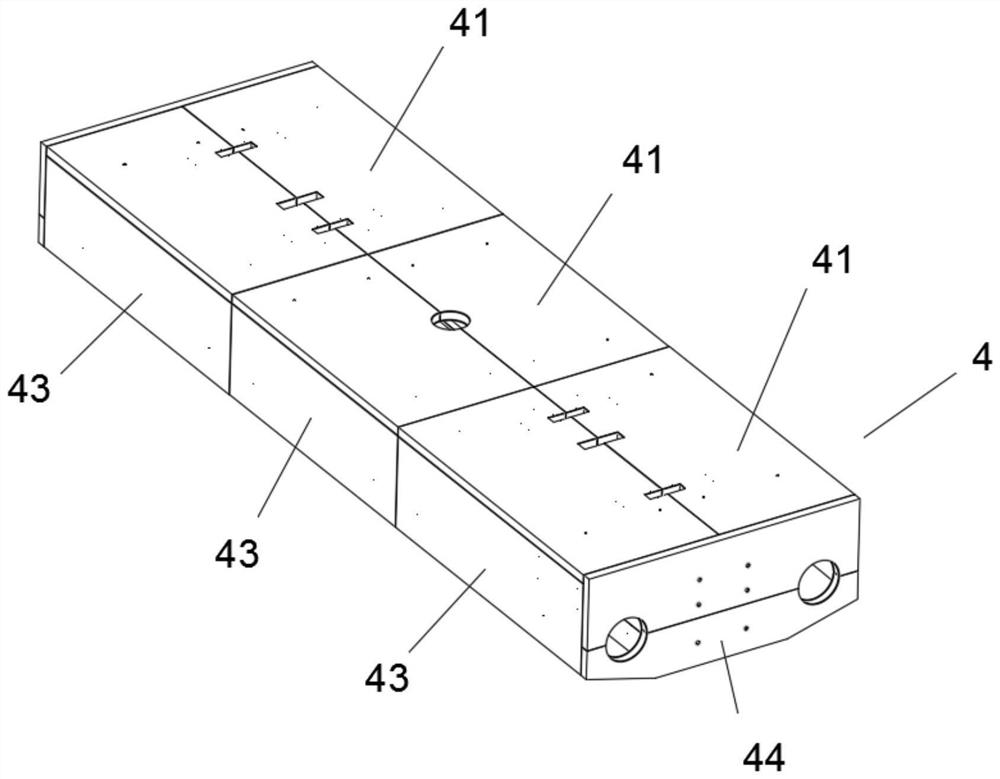

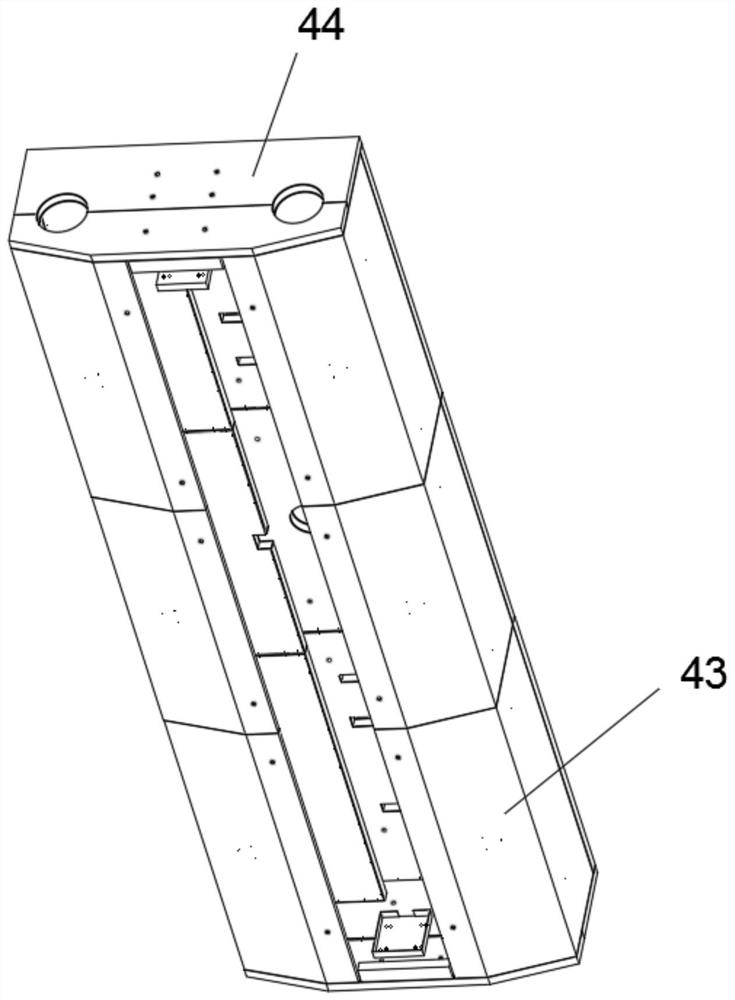

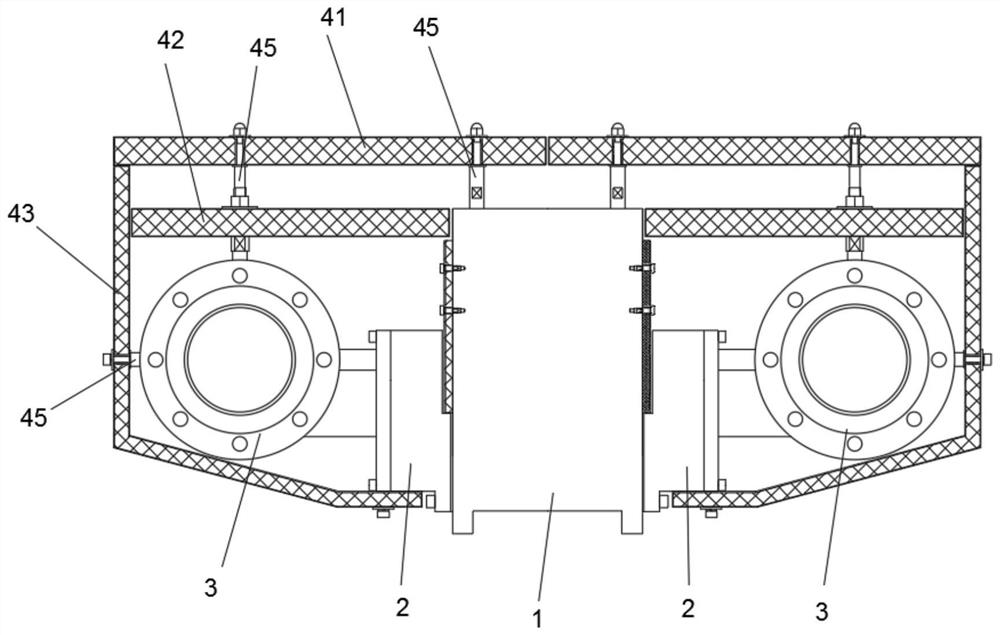

[0017] like Figure 1 to Figure 4 As shown, the present invention provides a shield for heat insulation of an extrusion die head, including a die head 1, a hot air box 2 is connected to both sides of the die head 1, and hot air boxes 2 are connected to the outside of the hot air box 2 Pipe 3, the outside of the hot air box 2, hot air pipe 3 and die head 1 is provided with a heat preservation cover 4, the heat preservation cover 4 includes a top plate 41, a middle plate 42, left and right side plates 43 and front and rear side plates 44, the left and right sides The bottom of the side plate 43 extends inwardly to the bottom surface of the hot air box 2, the left and right side plates 43 cover the sides and bottom surfaces of the hot air pipe 3 and the hot air box 2, and the middle plate 42 covers the hot air pipe 3 and the top surface of the hot air box 2, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com