A kind of multifunctional suspended concentrated fracturing fluid and its preparation method

A technology of suspension concentration and fracturing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of improving fracturing construction efficiency, reducing chemical storage tanks and dosing pipelines, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

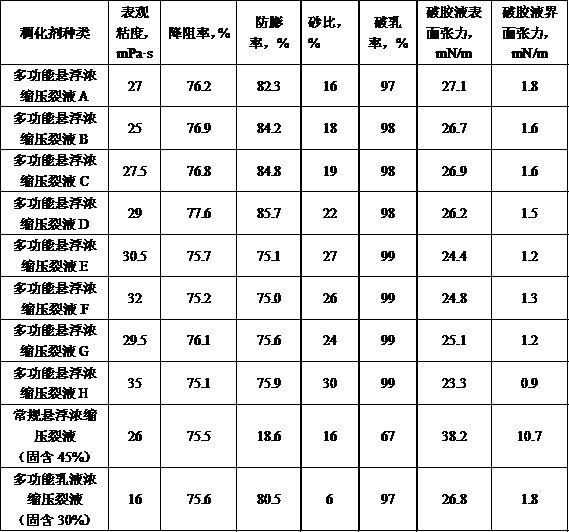

Examples

Embodiment 1

[0021] Under the conditions of rotating speed of 300r / min and temperature of 40℃, white oil, organic bentonite and Span 80 were added to the reaction kettle in turn, and after stirring for 1 hour, modified polyacrylamide and sodium dodecyl sulfonate were added to the reaction In the kettle, the multifunctional suspension concentrated fracturing fluid A was prepared after stirring for 1 hour.

[0022] In the above suspension concentrated fracturing fluid

[0023] White oil accounts for 50% of the total mass;

[0024] Organic bentonite accounts for 2% of the total mass;

[0025] Span 80 accounts for 2% of the total mass;

[0026] Modified polyacrylamide accounts for 45% of the total mass;

[0027] Sodium dodecyl sulfonate accounts for 1% of the total mass;

[0028] The modified polyacrylamide is prepared by copolymerization of 67% acrylamide, 20% 2-acrylamide-2-methylpropanesulfonic acid and 13% dimethyldiallyl ammonium chloride. obtained, the molecular weight is 25 million...

Embodiment 2

[0031] Under the conditions of rotating speed of 300r / min and temperature of 40℃, diesel oil, organic bentonite and Op-10 were added to the reaction kettle in turn, and after stirring for 1 hour, modified polyacrylamide and sodium tetradecyl sulfonate were added to the reaction kettle in turn. , the multifunctional suspension concentrated fracturing fluid B was prepared after continuous stirring for 1 h.

[0032] In the above suspension concentrated fracturing fluid

[0033] Diesel accounted for 49% of the total mass;

[0034] Organic bentonite accounts for 4% of the total mass;

[0035] Op-10 accounts for 1.5% of the total mass;

[0036] Modified polyacrylamide accounts for 44% of the total mass;

[0037] Sodium tetradecyl sulfonate accounts for 1.5% of the total mass;

[0038] The modified polyacrylamide is obtained by the copolymerization of 73% acrylamide, 11% acryloyl morpholine and 16% trimethylallyl ammonium chloride, with a molecular weight of 22 million and a part...

Embodiment 3

[0041] Under the condition of rotating speed of 300r / min and temperature of 40℃, kerosene, organic bentonite and Tween 60 were added to the reaction kettle in turn, and after stirring for 1 hour, modified polyacrylamide and sodium hexadecyl sulfonate were added to the reaction kettle in turn. , the multifunctional suspension concentrated fracturing fluid C was prepared after continuing to stir for 1 h.

[0042] In the above suspension concentrated fracturing fluid

[0043] Kerosene accounts for 48% of the total mass;

[0044]Organic bentonite accounts for 3% of the total mass;

[0045] Tween 60 accounts for 2% of the total mass;

[0046] Modified polyacrylamide accounts for 46% of the total mass;

[0047] Sodium cetyl sulfonate accounts for 1% of the total mass;

[0048] The modified polyacrylamide is obtained by the copolymerization of 65% acrylamide and acrylic acid, 12% 2-vinylpyridine and 23% acryloyloxyethyltrimethyl ammonium chloride, and has a molecular weight of 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com