Automatic beveling device for flame cutting

A bevel device and flame cutting technology, which is applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult flame cutting, etc., and achieve the goals of simplifying software compilation, large cutting angle, and improving quality and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

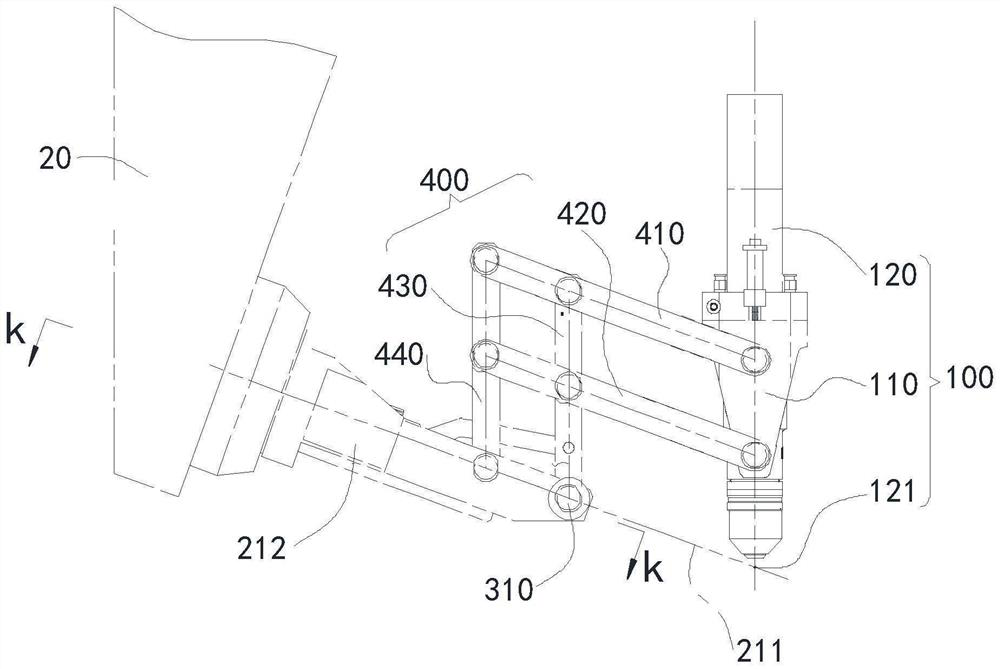

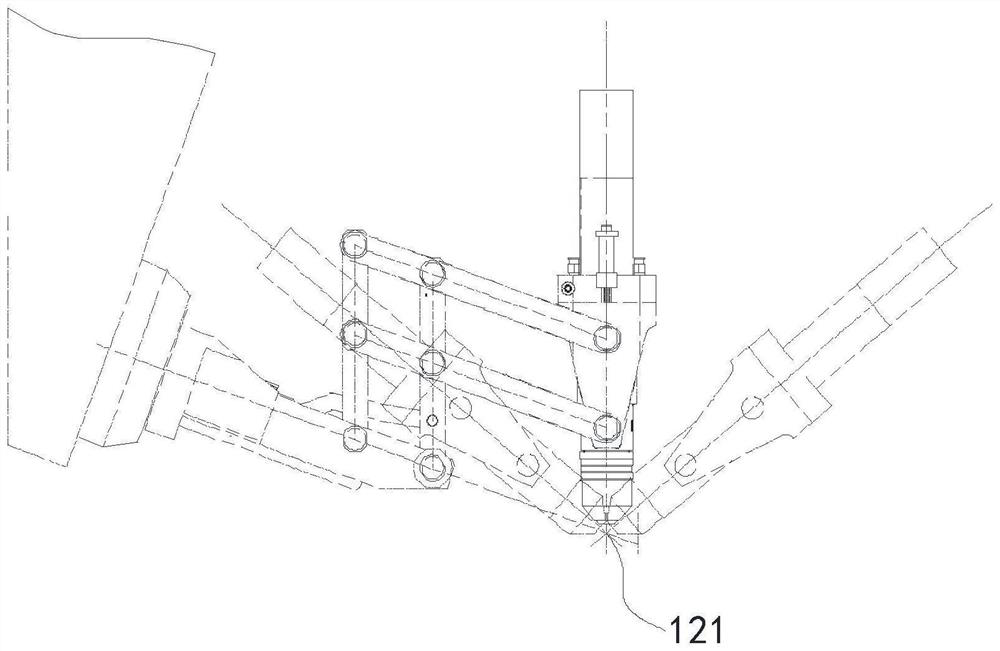

[0023] The embodiment of the present application provides an automatic beveling device for flame cutting, which solves the technical problem in the related art that the flame cutting is difficult due to the uncertain size and cutting position of the plate to be flame cut.

[0024] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

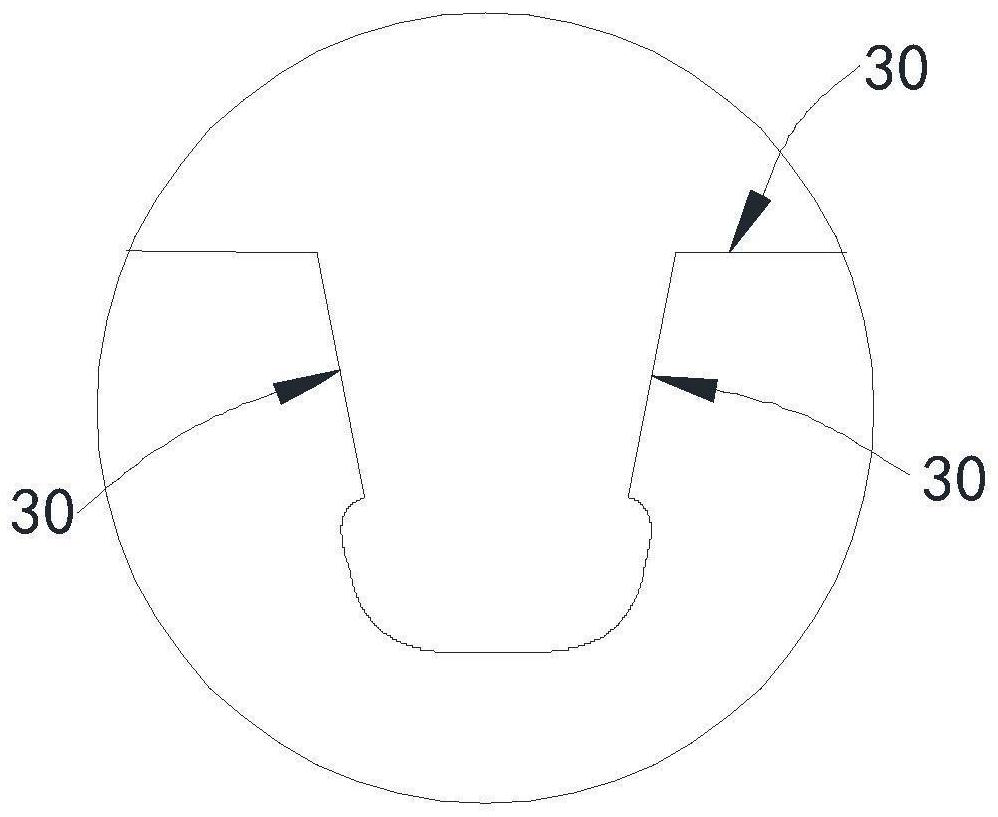

[0025] An automatic beveling device for flame cutting, comprising a gun body clamping assembly, a horizontal rotation mechanism, a longitudinal rotation mechanism and a four-bar linkage, the gun body clamping assembly includes a clamp and a flame cutting torch passing through the clamp The horizontal rotary mechanism includes a rotary shell and a first drive assembly to drive the rotary shell to rotate, the rotary shell is rotatably mounted on the cutting base box, and the longitudinal rotary mechanism includes a drive shaft and a second drive as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com