Manufacturing method of special essence with good fragrance-retaining effect for spinning

A manufacturing method and a technology for essence, which are applied in the field of essence and fragrance, can solve the problems of insignificant fragrance retention effect and poor feeling effect, and achieve the effects of good fragrance retention effect and strong fragrance expression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

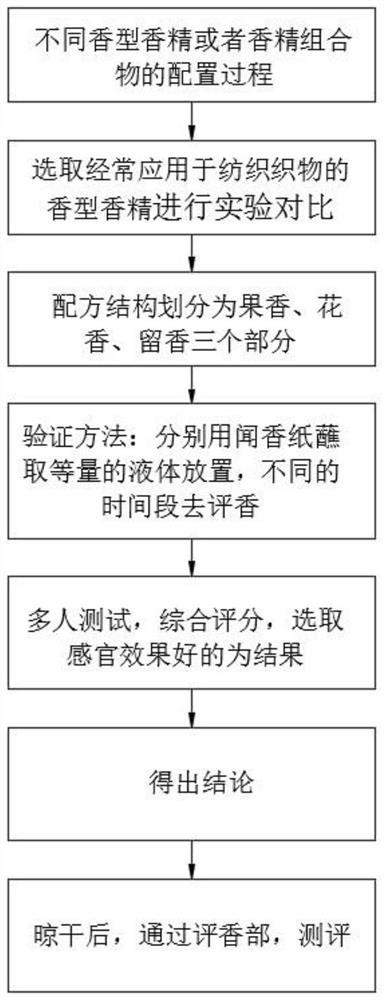

[0037] Prepare different fragrance flavors or flavor bases, and then compare them with different flavor flavors or compounds; weigh all raw materials liquid or solid into a container according to the formula in the experimental area, add the rotor, cover the lid, and put Set the number of revolutions on the digital display constant temperature magnetic stirrer; after the sample is configured, put it into the corresponding experimental bottle, paste the corresponding sample number, name, date and other sample information, then seal it, and store it in a cool and dry place; select the sample that is often used in textiles According to the above configuration process, the fragrance products of fabrics are configured; verification method: dip the same amount of liquid with scented paper and place them in different time periods (0h 2h 5h 8h 1t 2t 3t 5t 10t 12t 15t 21t 28t) To evaluate the fragrance, multiple people tested, comprehensively scored, and selected the best sensory effect...

Embodiment 2

[0039]Prepare different fragrance flavors or flavor bases, and then compare them with different flavor flavors or compounds; weigh all raw materials liquid or solid into a container according to the formula in the experimental area, add the rotor, cover the lid, and put Set the number of revolutions on the digital display constant temperature magnetic stirrer; the number of revolutions set increases with the increase of weight for different experimental weights. It is better to rotate the liquid evenly, and there is a vortex in the middle of the horizontal plane. Mix and stir evenly, and the stirring time depends on the liquid. After stirring until clear and transparent without solids, stir for another 10 minutes as a guideline. (In case of solids that have not been dissolved for a long time, heat in a constant temperature water bath at 55°C until dissolved.) The sample is prepared and put into the corresponding experimental bottle. Paste the sample information such as the corr...

Embodiment 3

[0041] Prepare different fragrance flavors or flavor bases, and then compare them with different flavor flavors or compounds; weigh all raw materials liquid or solid into a container according to the formula in the experimental area, add the rotor, cover the lid, and put Set the number of revolutions on the digital display constant temperature magnetic stirrer; the number of revolutions set increases with the increase of weight for different experimental weights. It is better to rotate the liquid evenly, and there is a vortex in the middle of the horizontal plane. Mix and stir evenly, and the stirring time depends on the liquid. After stirring until clear and transparent without solids, stir for another 10 minutes as a guideline. (In case of solids that have not been dissolved for a long time, heat in a constant temperature water bath at 55°C until dissolved.) The sample is prepared and put into the corresponding experimental bottle. Paste the sample information such as the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com