Steam exhaust structure for cooking device and cooking device with same

A technology of cooking device and exhaust port, which is applied in household utensils, kitchen utensils, steam cooking utensils, etc. It can solve the problems of high price, large volume of high temperature pump, and affecting food forming inner tank structure, so as to improve efficiency and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

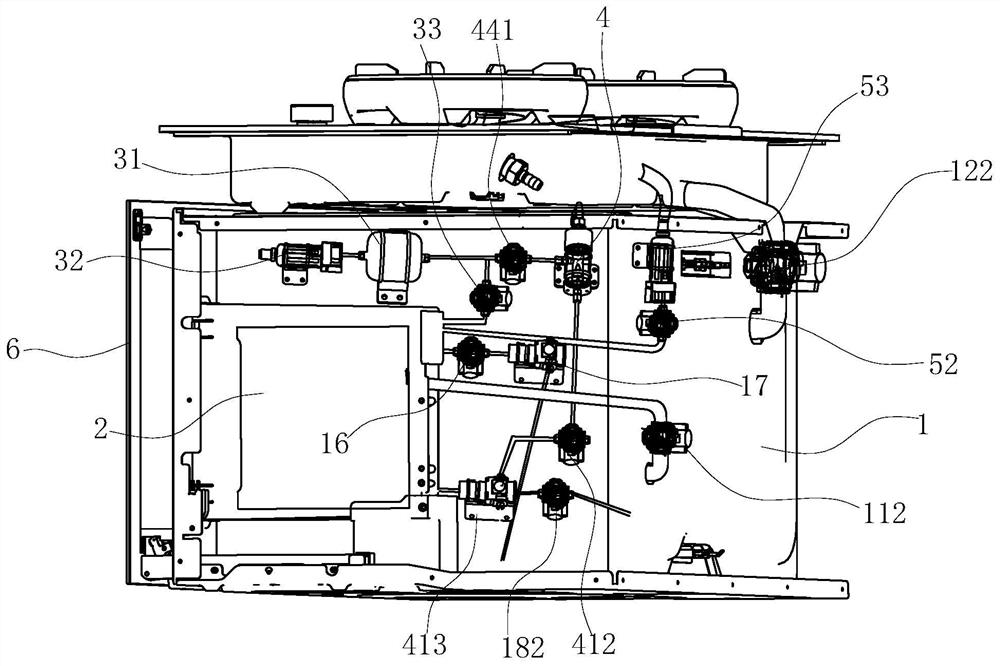

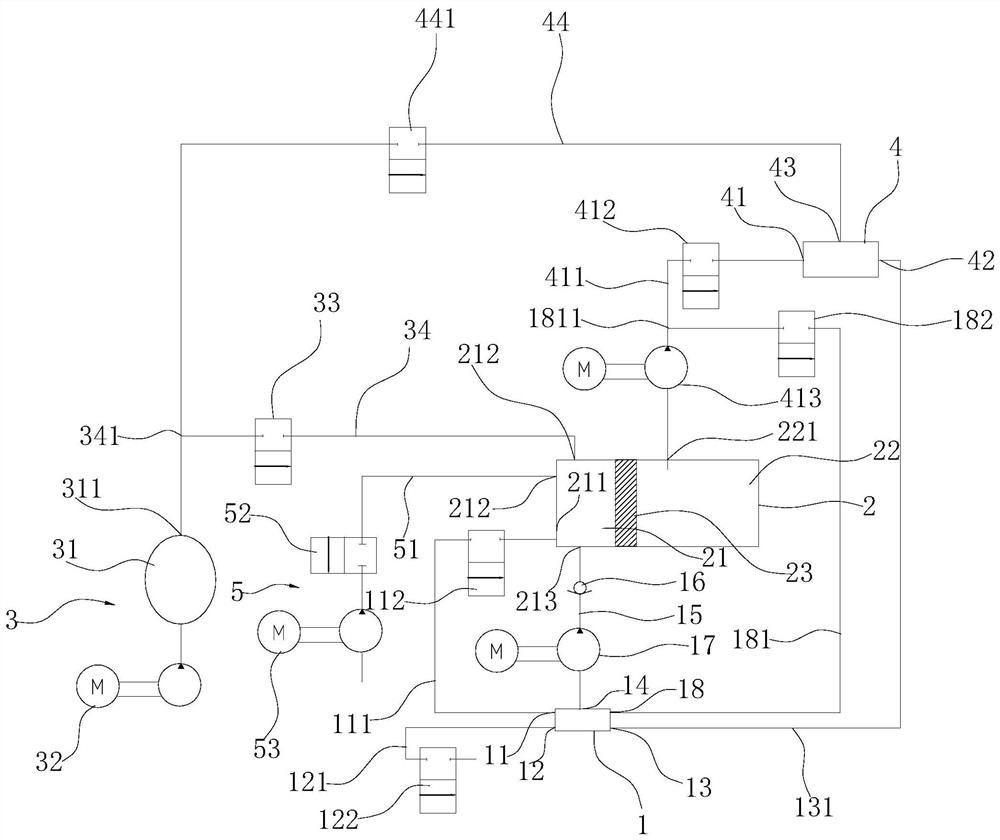

[0027] Such as Figure 1~2 As shown, a cooking device, such as an integrated steamer and oven, an integrated stove steamer and oven, etc., the cooking device in the present invention is an integrated stove steamer and oven. The above-mentioned cooking device has a steam exhaust structure, and the exhaust structure includes an inner tank 1 and a water tank 2 , and a door body 6 is closed on the front opening of the inner tank 1 .

[0028] The shape of the above-mentioned water tank 2 is square, and its inner chamber is divided into a waste water chamber 21 and a water purification chamber 22 by a vertical heat conduction filter layer 23, wherein the water purification chamber 22 is provided with a water injection port (not shown). Add clean cold water to the clean water chamber 22 through the water injection port. Further, when a certain pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com