Design method for progressive collapse resistance of structure and ultimate bearing capacity calculation method

A technology of ultimate bearing capacity and calculation method, applied in truss-type structures, special data processing applications, instruments, etc., can solve the problems that the structure cannot meet the multi-hazard design and fortification requirements, increase the cost, and be difficult to construct, and improve the continuous resistance of the structure. Collapse performance, conflict mitigation, adaptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

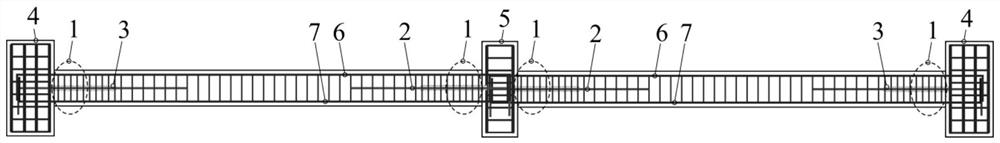

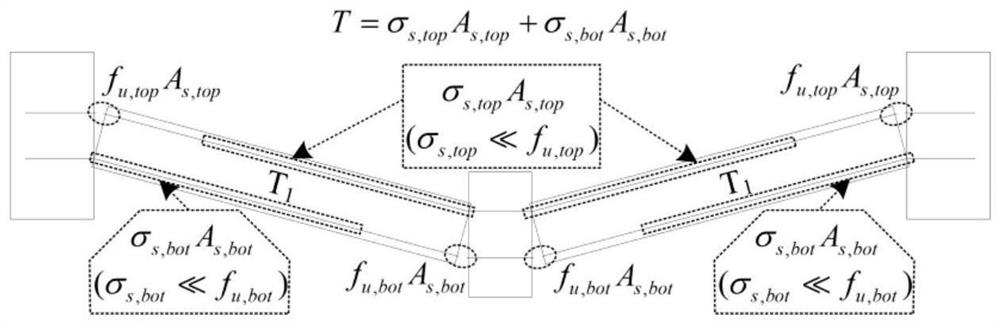

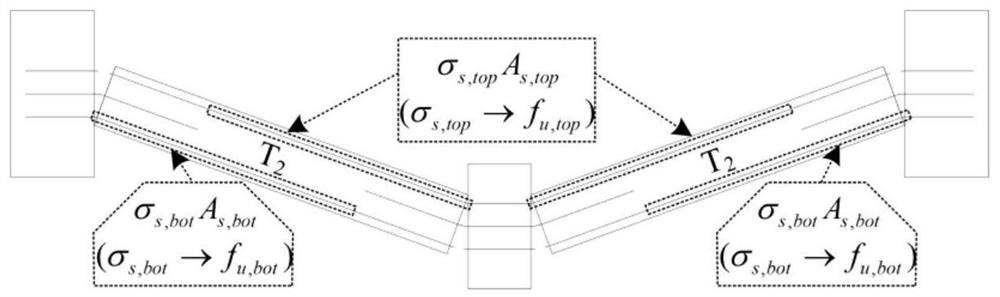

[0063] Figure 4 In order to design a sub-structure designed in conventional methods and a continuous collapse resistance to a sub-structure designed by the invention. The design technique proposed in the present invention is a longitudinal short steel bib 2 in which a half-high positional addition and concrete partially delayed longitudinal short steel bib 2 is partially delayed in the near-side reinforcement, and the concrete is bonded to the concrete. accomplish. As shown in FIG. 2 (a), a sub-structure designed according to conventional methods, at the top longitudinal rib 5 and the near-middle column 6 bottom longitudinal ribs 7 due to the change concentration, the near-edge column 4 is broken due to the change of the concentrated phenomenon. The presence of beam end 1 bottom longitudinal ribs 7 and the near-middle column 6 longitudinal rib 5 can continue to provide resistance, but the power can be provided, which is mainly due to two reasons: 1 Beam 5,7 tensile properties hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com