Vertical support stress uniform distribution device for building reinforcement engineering

A vertical support and stress technology, applied in construction, building maintenance, building construction, etc., can solve problems such as excessive support deflection, poor support capacity, poor protection of spherical mating surfaces, difficult observation and monitoring, etc., to achieve convenient observation and monitoring, strong working stability and practicability, and evenly arranged effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

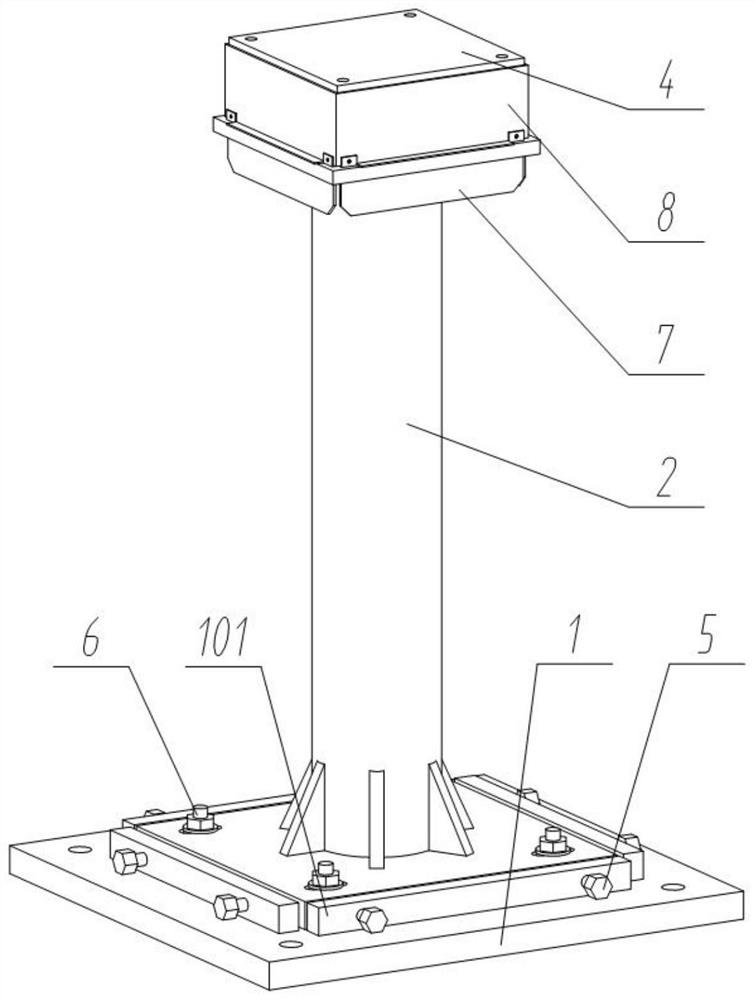

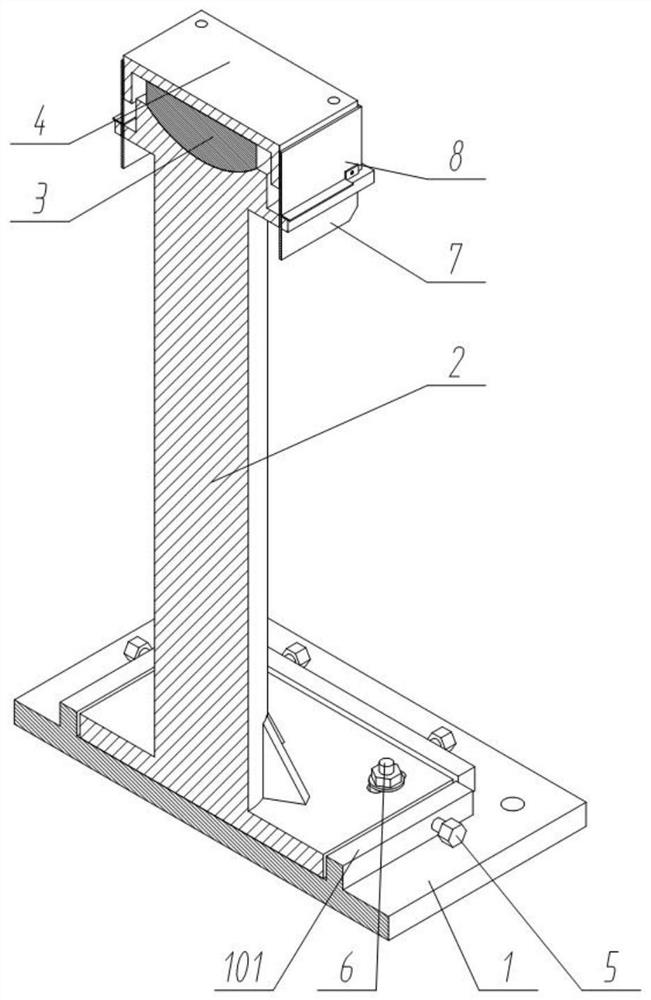

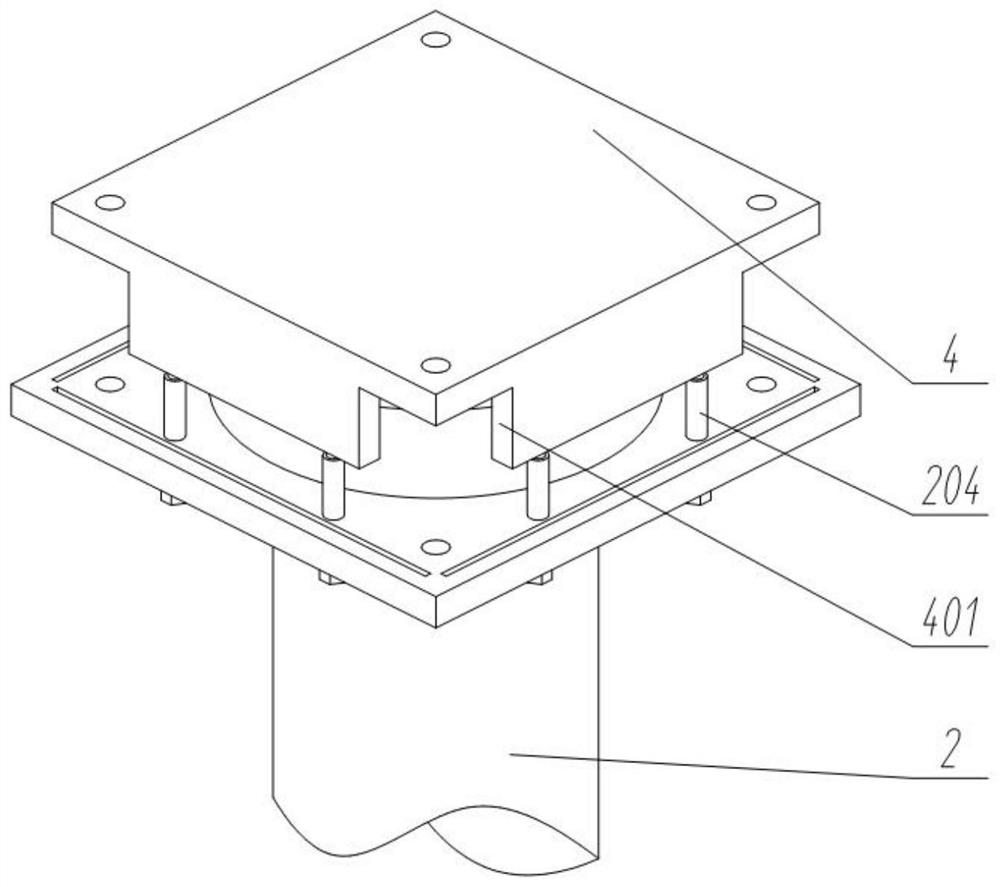

[0057] Example: Please refer to Figure 1 to Figure 9 :

[0058] The invention proposes a device for uniform distribution of vertical support stress in building reinforcement engineering, comprising: a lower mounting base 1; the lower mounting base 1 is installed on the base surface through expansion bolts; The solid component is fastened to the upper end surface of the lower mounting seat 1; in addition, according to the embodiment of the present invention, as Figure 6As shown, the adjustable fastening assembly also includes: adjusting block chute 102, four sets of adjusting block chute 102 are arranged in total, and the four sets of adjusting block chute 102 are evenly arranged on the lower mounting base 1, and the adjusting block chute 102 It is opened front and rear; the lower seat slider bolt 6 is slidably connected in the adjustment block chute 102, and in use, the lower seat slider bolt 6 is guided in the front and rear directions through the adjustment block chute 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com