Raw butadiene rubber rubber and preparation method thereof

A technology of cis-butadiene rubber and raw rubber, applied in the field of raw rubber, can solve the problems of limited effect of cis-butadiene rubber on tensile strength and tear strength, and save technology development and production costs, great value, and technical transformation. low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

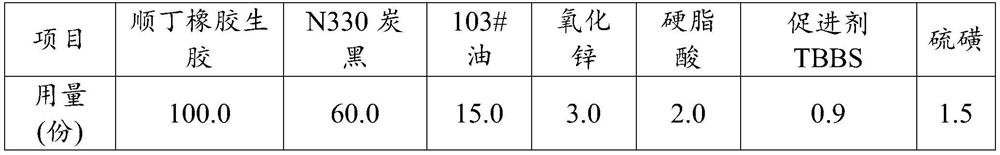

Method used

Image

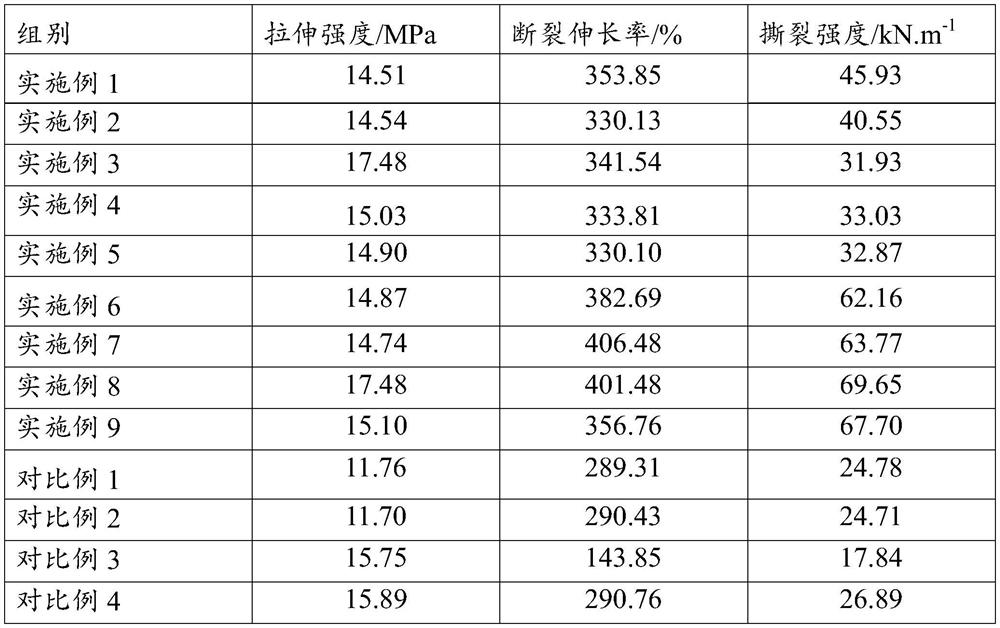

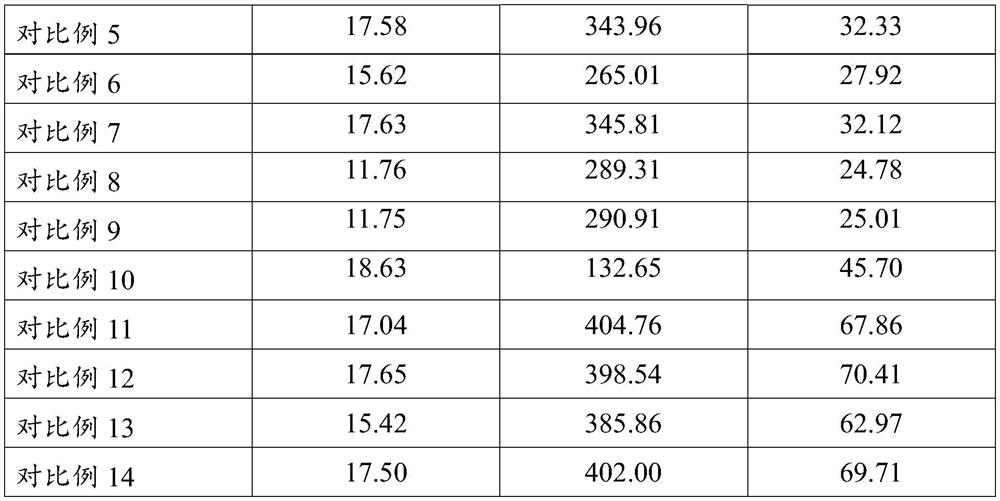

Examples

Embodiment 1

[0038] A method of preparing a tannut rubber gum comprising the following steps:

[0039]S1, a refined butadiene monomer, a cycloalkylene solvent, and a catalyst together with the polymerization reactor, mixed, the polymerization reaction, the reaction temperature is 75 ° C, the reaction time is 1.5 h, the conversion rate is 75 ~ 85%, the reaction After getting the collapse;

[0040] S2, the gel prepared by step S1 is mixed with the terminator, the antioxidant, and the retardation is fed into the stopping tank, and the mixture is uniformly obtained, and the mixture is transferred to the gum tank;

[0041] S3, under conditions of temperature of 95 ° C, the mixing liquid in step S2 is sent to the condenser, and mixed with a hydrocarboxylate aqueous solution of a polycarboxylate is mixed for agglomerate reaction, stir for 1 h, condensed rubber particles, remove solvent and unreacted Butadiene monomer; dried solvent and unreacted butadiene monomer to the recovery refining system cycle...

Embodiment 2

[0047] A method of preparing a tannut rubber gum comprising the following steps:

[0048] S1, a refined butadiene monomer, a cycloalkylene solvent, and a catalyst together with the polymerization reactor, mixed, the polymerization reaction, the reaction temperature is 75 ° C, the reaction time is 1.5 h, the conversion rate is 75 ~ 85%, the reaction After getting the collapse;

[0049] S2, the gel prepared by step S1 is mixed with the terminator, the antioxidant, and the retardation is fed into the stopping tank, and the mixture is uniformly obtained, and the mixture is transferred to the gum tank;

[0050] S3, under conditions of temperature of 95 ° C, the mixing liquid in step S2 is sent to the condenser, and mixed with a hydrocarboxylate aqueous solution of a polycarboxylate is mixed for agglomerate reaction, stir for 1 h, condensed rubber particles, remove solvent and unreacted Butadiene monomer; dried solvent and unreacted butadiene monomer to the recovery refining system cycl...

Embodiment 3

[0056] A method of preparing a tannut rubber gum comprising the following steps:

[0057] S1, a refined butadiene monomer, a cycloalkylene solvent, and a catalyst together with the polymerization reactor, mixed, the polymerization reaction, the reaction temperature is 75 ° C, the reaction time is 1.5 h, the conversion rate is 75 ~ 85%, the reaction After getting the collapse;

[0058] S2, the gel prepared by step S1 is mixed with the terminator, the antioxidant, and the retardation is fed into the stopping tank, and the mixture is uniformly obtained, and the mixture is transferred to the gum tank;

[0059] S3, under conditions of temperature of 95 ° C, the mixing liquid in step S2 is sent to the condenser, and mixed with a hydrocarboxylate aqueous solution of a polycarboxylate is mixed for agglomerate reaction, stir for 1 h, condensed rubber particles, remove solvent and unreacted Butadiene monomer; dried solvent and unreacted butadiene monomer to the recovery refining system cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com