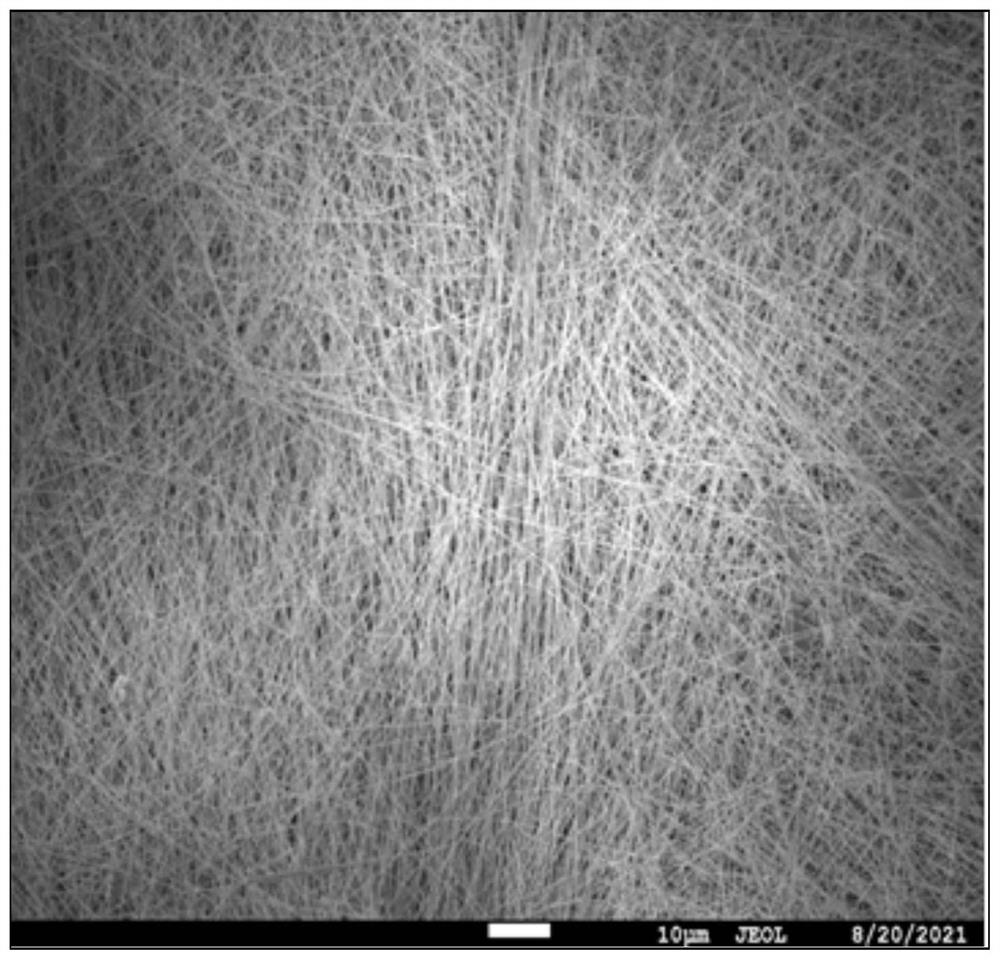

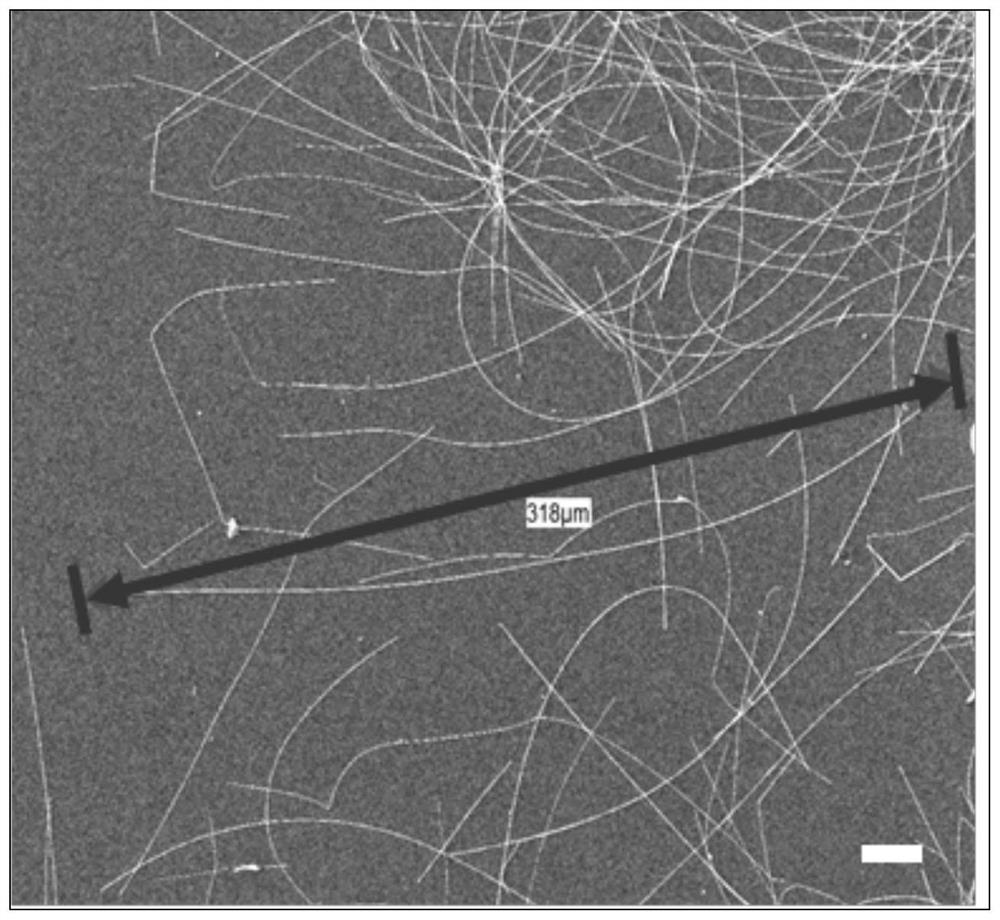

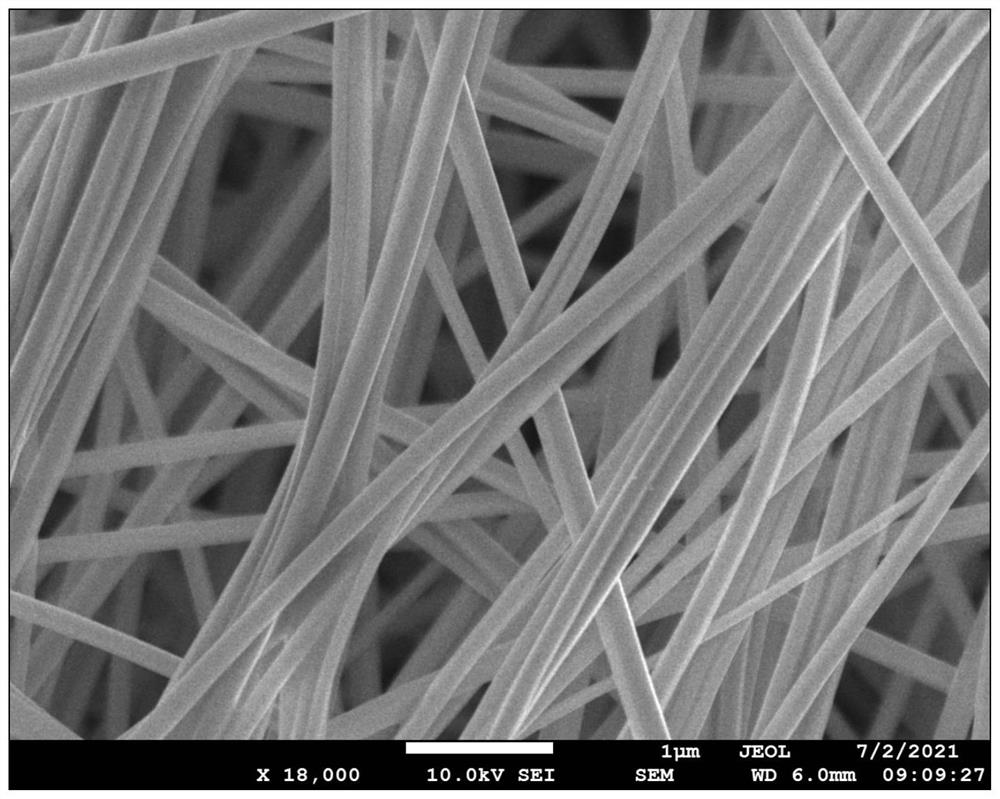

Preparation method of ultra-long nano silver wire material

A nano-silver wire, ultra-long technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high viscosity of product solution, harsh reaction conditions, difficult washing, etc., and achieve simple equipment. , low cost, controllable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] Step 1. Add glucose and polyvinylpyrrolidone to deionized water and stir evenly to obtain a clear solution; the molar ratio of glucose, polyvinylpyrrolidone and water is 1:0.1:280, and the molar mass of glucose is 0.01mmol ;

[0031] Step 2, adding copper sulfate solution to the clarified solution obtained in step 1 and stirring evenly to obtain mixed solution A; the molar mass of copper sulfate in the copper sulfate solution is 4.8mmol;

[0032] Step 3, adding sodium chloride solution to the mixed solution A obtained in step 2 and stirring uniformly to obtain mixed solution B; the molar mass of sodium chloride in the sodium chloride solution is 1 mmol;

[0033] Step 4, add silver nitrate solution dropwise to the mixed solution B in step 3 and stir to obtain a reaction solution, then transfer the reaction solution to a hydrothermal reaction kettle, and react at 110° C. for 16 hours to obtain a flocculent product; ...

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] Step 1. Add glucose and polyvinylpyrrolidone to deionized water and stir evenly to obtain a clear solution; the molar ratio of glucose, polyvinylpyrrolidone and water is 1:0.05:400, and the molar mass of glucose is 0.01mmol ;

[0039] Step 2, adding copper sulfate solution to the clarified solution obtained in step 1 and stirring uniformly to obtain mixed solution A; the molar mass of copper sulfate in the copper sulfate solution is 6 mmol;

[0040] Step 3, adding sodium chloride solution to the mixed solution A obtained in step 2 and stirring uniformly to obtain mixed solution B; the molar mass of sodium chloride in the sodium chloride solution is 2mmol;

[0041] Step 4, add silver nitrate solution dropwise to the mixed solution B in step 3 and stir to obtain a reaction solution, then transfer the reaction solution to a hydrothermal reaction kettle, and react at 130° C. for 20 hours to obtain a flocculent product;...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] Step 1. Add glucose and polyvinylpyrrolidone into deionized water and stir evenly to obtain a clear solution; the molar ratio of glucose, polyvinylpyrrolidone and water is 1:0.08:560, and the molar mass of glucose is 0.01mmol ;

[0047] Step 2, adding copper sulfate solution to the clarified solution obtained in step 1 and stirring uniformly to obtain mixed solution A; the molar mass of copper sulfate in the copper sulfate solution is 5.4 mmol;

[0048] Step 3, adding sodium chloride solution to the mixed solution A obtained in step 2 and stirring uniformly to obtain mixed solution B; the molar mass of sodium chloride in the sodium chloride solution is 1.3mmol;

[0049] Step 4, add silver nitrate solution dropwise to the mixed solution B in step 3 and stir to obtain a reaction solution, then transfer the reaction solution to a hydrothermal reaction kettle, react at 120° C. for 14 hours, and obtain a flocculent prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com