Calibration method for flow calibration coefficient of multi-component mixed gas

A technology of mixed gas and calibration coefficient, applied in the direction of testing/calibrating volume flow, etc., can solve problems such as difficulty in effectively guaranteeing accuracy, calibration coefficient error, weakening objective error, etc., and achieves the effect of eliminating objective error, easy to implement, and widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

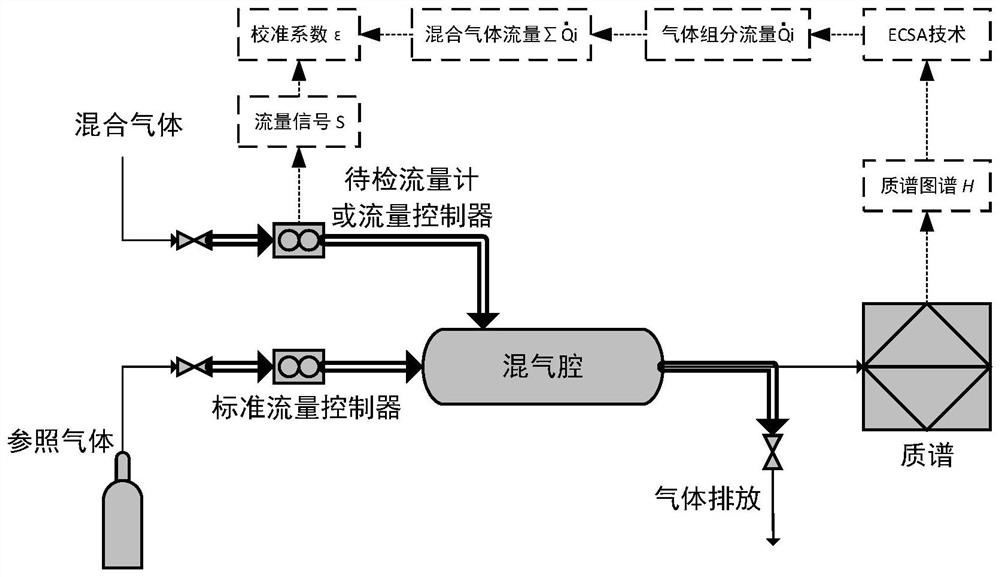

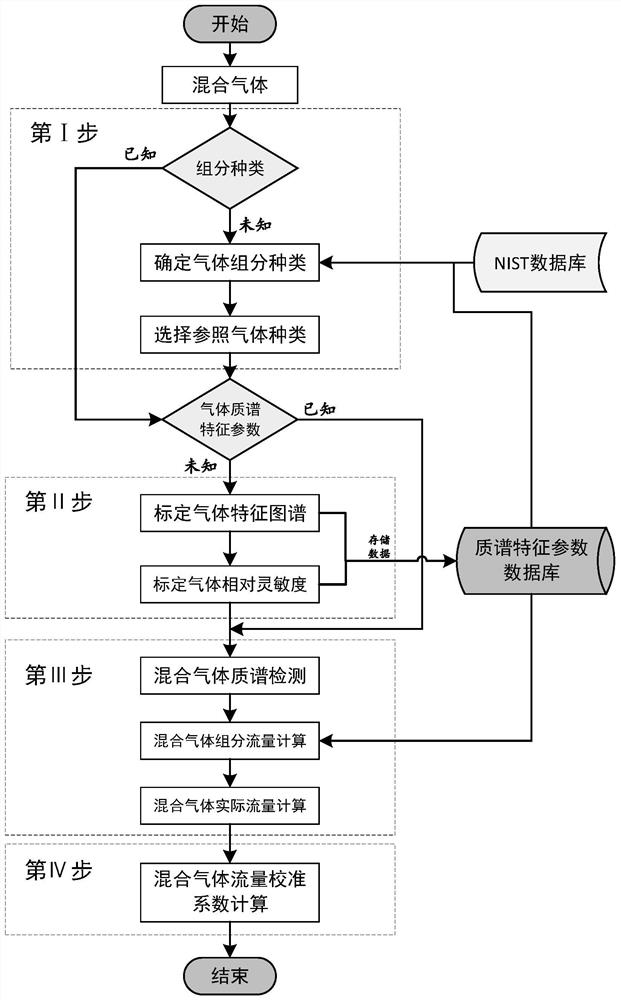

[0109] Taking the calibration coefficient calibration of the conventional gas mass flow controller as an example, through the calibration of the flow calibration coefficients of the two mixed gases, the two mixed gases are the mixed gas 1(N 2 with O 2 Mixed, concentrations are 20% and 80%), mixed gas 2 (N 2 , O 2 , CO 2 Mixed, the concentrations were 20%, 30% and 50%). In order to effectively introduce the calibration process, the two mixed gases are still regarded as unknown multi-component gases, and the calibration procedure is strictly described according to the process.

[0110] Step 1: Determine the composition of the gas mixture

[0111] Inject the two mixed gases into the figure 1 In the device shown, mass spectrograms were obtained as image 3 , 4 shown. Combined with the NIST database, it can be judged that the mixed gas 1 consists of N 2 with O 2 Composed of two components, there are significant characteristic peaks at the mass-to-nucleus ratio m / z=28,32; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com