Nitrogen-filling electroslag process for cavity of nitrogen-containing steel hollow blank

A hollow billet and electroslag technology, which is applied in the field of nitrogen-charged electroslag process for nitrogen-containing steel hollow billets, can solve the problem that non-high value-added products cannot be produced economically, increase gas and inclusion content, increase power consumption and refractory materials Erosion and other problems, to achieve the effect of shortening smelting time, avoiding spillover fluctuations, improving production efficiency and quality assurance capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Taking the nitrogen-containing die steel P15 product that requires electroslag as an example, the process design steps are as follows:

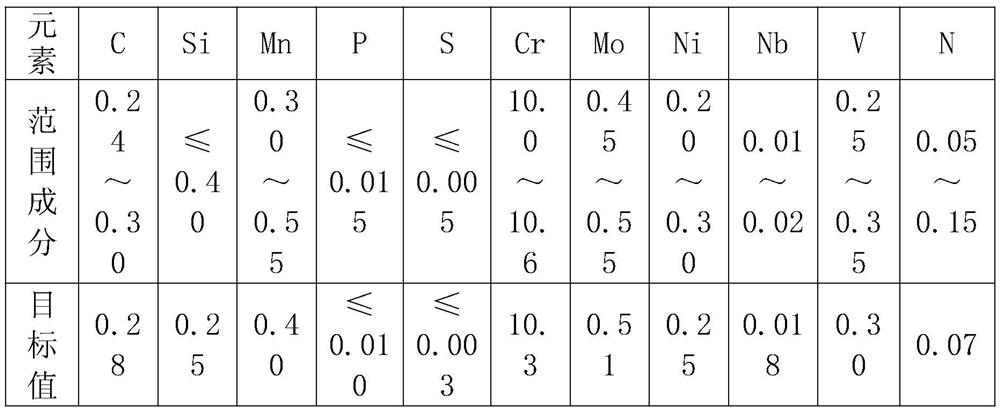

[0025] The chemical composition of die steel P15 is shown in the following table (mass percentage %):

[0026]

[0027] The elements that can fix nitrogen in the composition of this steel type are mainly Cr and V. According to the calculation of metallurgical formula, the optimum nitrogen content of nitrogen element in this steel type is 0.070% (mass percentage %).

[0028] The nitrogen-containing electroslag process of the nitrogen-containing steel hollow billet cavity of the present invention is different from the usual nitrogen-containing steel in which nitrogen element is added to the electrode billet and then electroslag. This process does not add nitrogen when the electrode billet is smelted, and adopts For the hollow electrode blank not containing nitrogen, nitrogen gas is injected from the reserved hole during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com