Convenient-to-assemble oxygen generator core

An oxygen generator and movement technology, applied in the field of oxygen generators, can solve the problems of unreasonable internal structure and weak heat dissipation mode of the oxygen generator, and achieve the effects of saving assembly time, improving production efficiency and reducing working temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be described in conjunction with the embodiment of the present invention. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained in the preparation of creative labor.

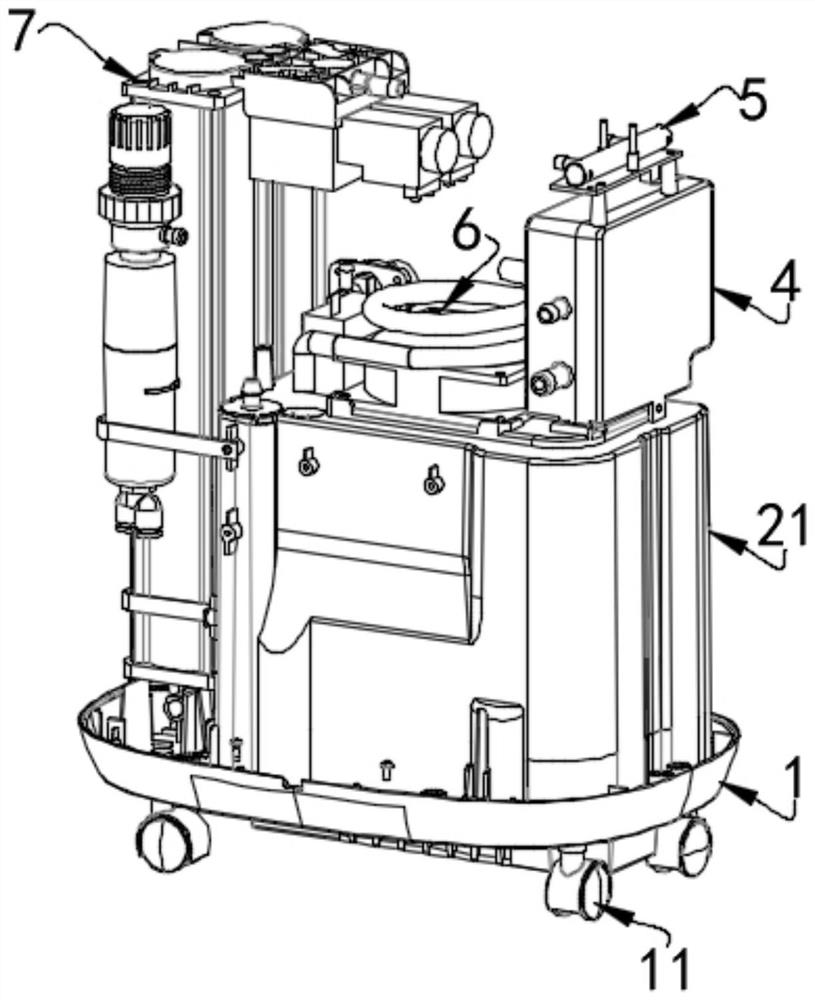

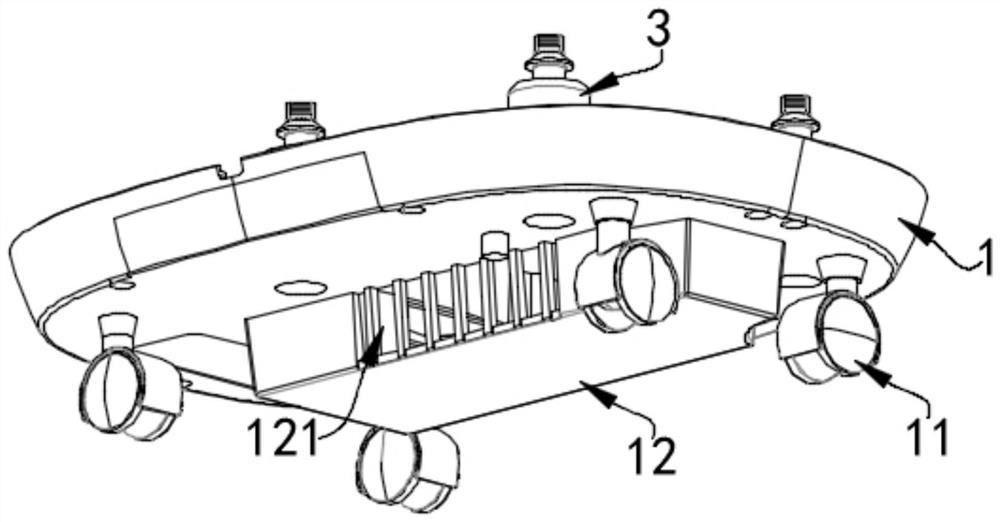

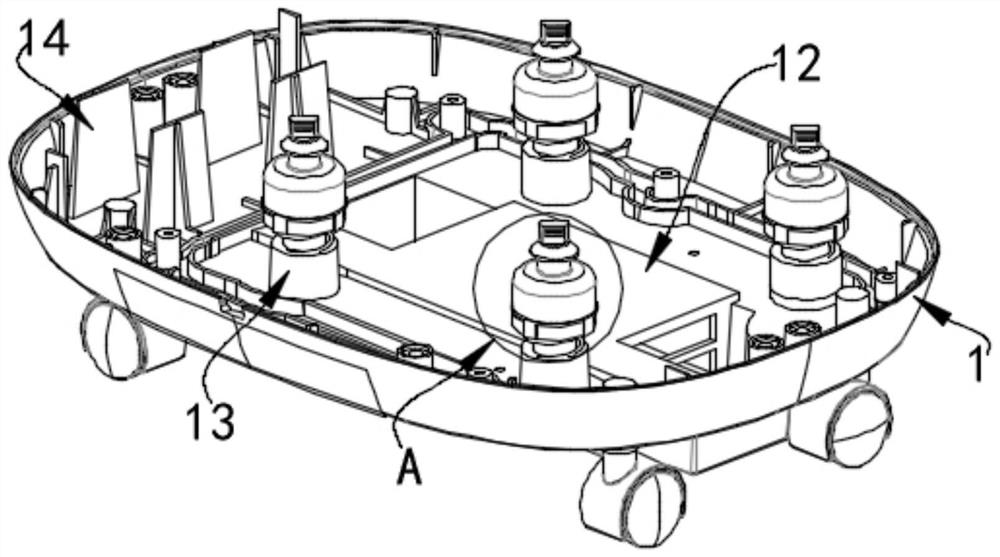

[0031] like figure 1 , The oxygen for facilitating movement of the assembly, includes a base 1, the base 1 has an elliptical configuration, its four corner ends of the bottom surface is provided with casters 11, above the base 1 is provided with a compressor 2, intake and exhaust muffler are integrally 4, 6 and molecular sieve adsorption tower fans 7, the equipment during operation, the compressor 2 compressing the sucked air introduced into the first exhaust muffler integrally 4, by molecular sieve adsorption deadening process then introduced into column 7 oxygen job, after completion of oxygen, nitrogen was aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com