Auxiliary support for motor on rice mill

A technology for auxiliary brackets and rice milling machines, which is applied in the directions of electromechanical devices, casings/covers/supports, electrical components, etc., which can solve the problem that the tightening force of the screws cannot be completely consistent, the deformation of the elastic rubber pad is uneven, and the assembly position of the motor is deviated. and other problems, to achieve the effect of convenient assembly, increased contact area, and reduced pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

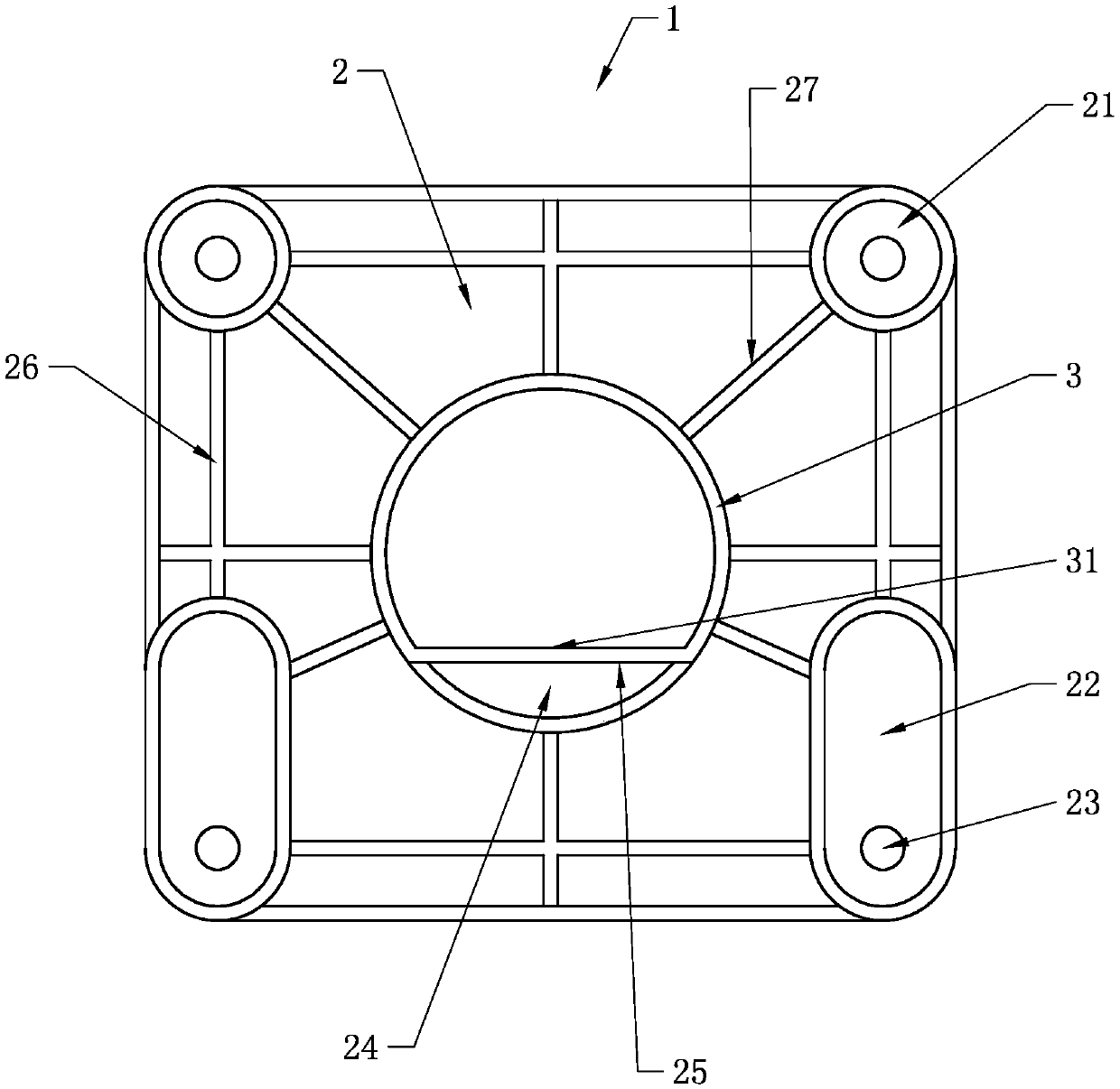

[0016] Such as figure 1 As shown, an auxiliary bracket for a motor on a rice milling machine includes a first body 1 of plastic material, the first body 1 is provided with a first flat plate 2 abutting against a fixed frame, and the first flat plate 2 is provided with a On the first end face of the joint, the side of the first flat plate 2 facing away from the first end face is provided with several first circular grooves 21 and first elongated grooves 22 that snap into the shell of the rice mill, the first circular grooves 21 and the first The groove bottoms of the elongated grooves 22 are provided with first through holes 23 through which the screw parts of the bolts pass.

[0017] In this embodiment, the first body 1 of plastic material is provided instead of the rubber pad, which has a certain supporting strength, ensures that the assembly of the motor does not deviate, and facilitates the assembly of the motor; also by providing the first flat plate 2 that is in contact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com