A pay-off reel for automatic assembly of detonators

An automatic assembly and pay-off reel technology, applied in the direction of offensive equipment, fuzes, weapon accessories, etc., to achieve the effect of reducing production operators, reducing labor intensity, and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

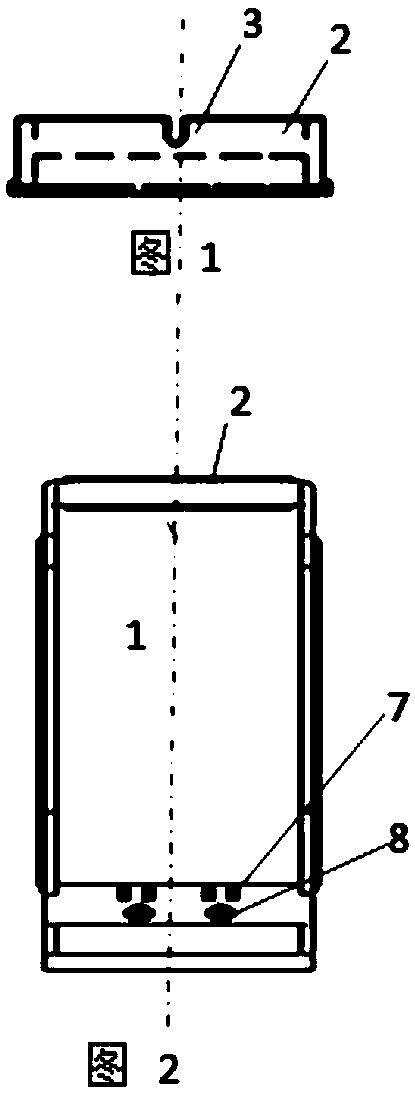

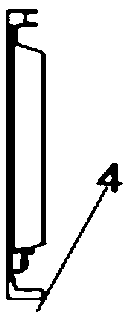

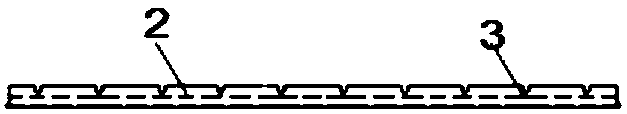

[0060] The shape of the present invention is a regular rectangular tray 1, the outer edge of the rectangular tray is provided with a convex frame 2 on opposite sides or around it, and at least one set of pluggable devices 3 is provided on one side of the convex frame 2, if there is a concave shape with a clamping and positioning function Clips or elastic "U"-shaped clips; the edge of the rectangular tray is symmetrically opposite to the side where the jamming device 3 is provided, and a push-pull boss 4 is provided on the edge of the rectangular tray for each working station mechanical device to push or pull out the pay-off reel; The inner side of the rectangular tray on one side of the jamming device 3 is provided with a clamping groove 5 for fixing the lead wire; a branch line frame 6 is provided in the rectangular tray; a link electric detonator or digital electronic device is provided in the rectangular tray on the opposite side of the jamming device 3 . The clamp (or colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com