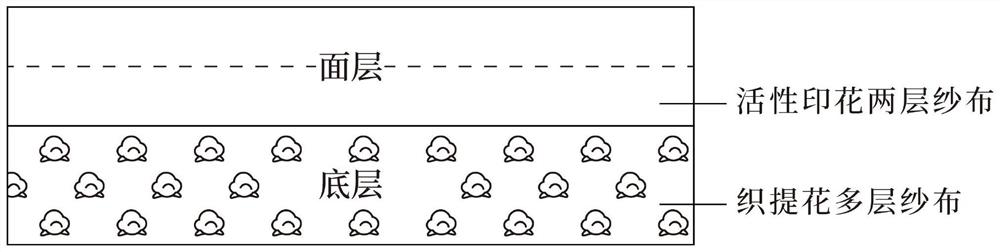

Lifting and printing multi-layer cloth composite quilt

A surface layer and bottom layer technology, applied in the field of textiles, can solve the problems of insufficiently delicate patterns and insufficient colors, and achieve the effect of beautiful colors, rich color layering, increasing interest and diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of printing-lifting multi-layer cloth composite quilt, its preparation method is as follows:

[0043] (1) The surface fabric is two layers of gauze with active printing layer, using 1 upper and 1 lower plain weave as the basic structure, and 32s / 1 single yarn as the raw material to weave the two layers of gauze and then carry out active printing according to the design pattern.

[0044] Described reactive printing process is as follows:

[0045] Reactive yarn dyeing: Oxygen bleaching at 110°C for 50 minutes on the bobbin dyeing machine, then neutralization and deoxidation at 50°C for 20 minutes, then active dyeing at 60°C for 30 minutes, washing after dyeing, soaping at 95°C for 30 minutes after washing, and then 70°C Wash with water for 15 minutes, fix the color at 50°C for 30 minutes after washing, soften and wax at 40°C for 20 minutes, steam dry at 120°C to obtain colored yarn;

[0046] The dyed yarn is oxygen bleached at 110°C for 20 minutes, then neutralize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com