Efficient driving method and device of mini LED

An LED driving and high-efficiency driving technology, applied in the use of semiconductor lamps, electrical components, energy-saving control technology, etc., can solve the problems of poor applicability and low efficiency of MiniLED, and achieve the effect of improving accuracy, high driving efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

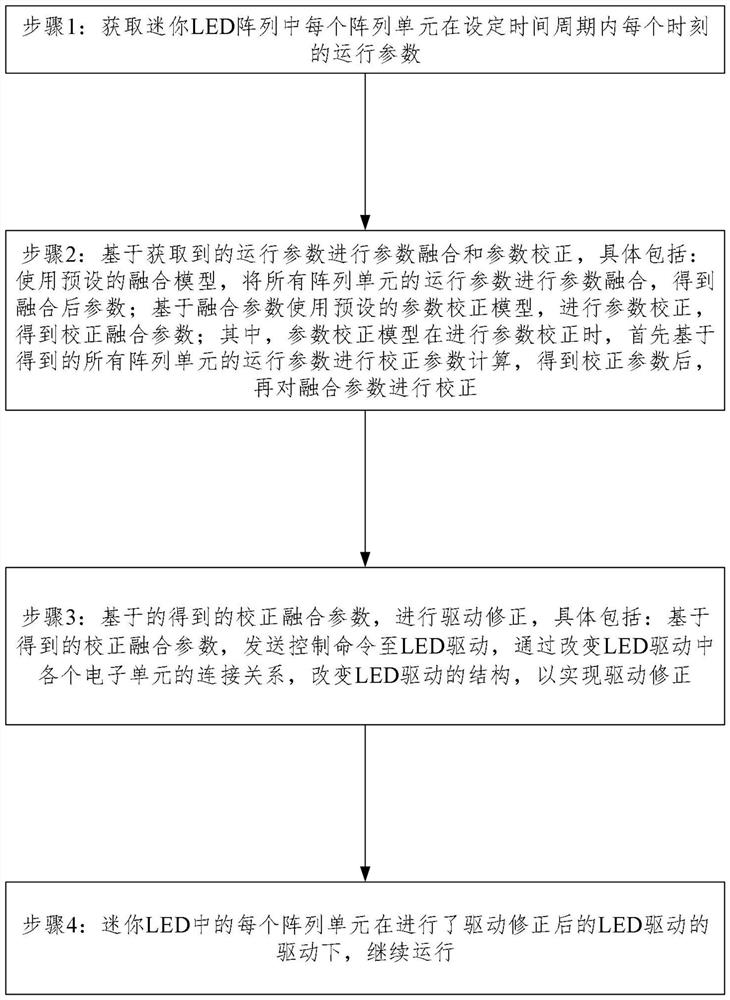

[0036] like figure 1 As shown, a highly efficient driving method for mini LEDs, the method performs the following steps:

[0037] Step 1: Obtain the operating parameters of each array unit in the mini LED array at each moment within the set time period;

[0038] Step 2: Perform parameter fusion and parameter correction based on the obtained operating parameters, specifically including: using the preset fusion model, performing parameter fusion on the operating parameters of all array units to obtain the fused parameters; using the preset parameters based on the fused parameters Correcting the model to perform parameter correction to obtain corrected fusion parameters; wherein, when performing parameter correction, the parameter correction model first calculates the corrected parameters based on the obtained operating parameters of all array units, and then corrects the fusion parameters after obtaining the corrected parameters;

[0039] Step 3: Carry out driver correction bas...

Embodiment 2

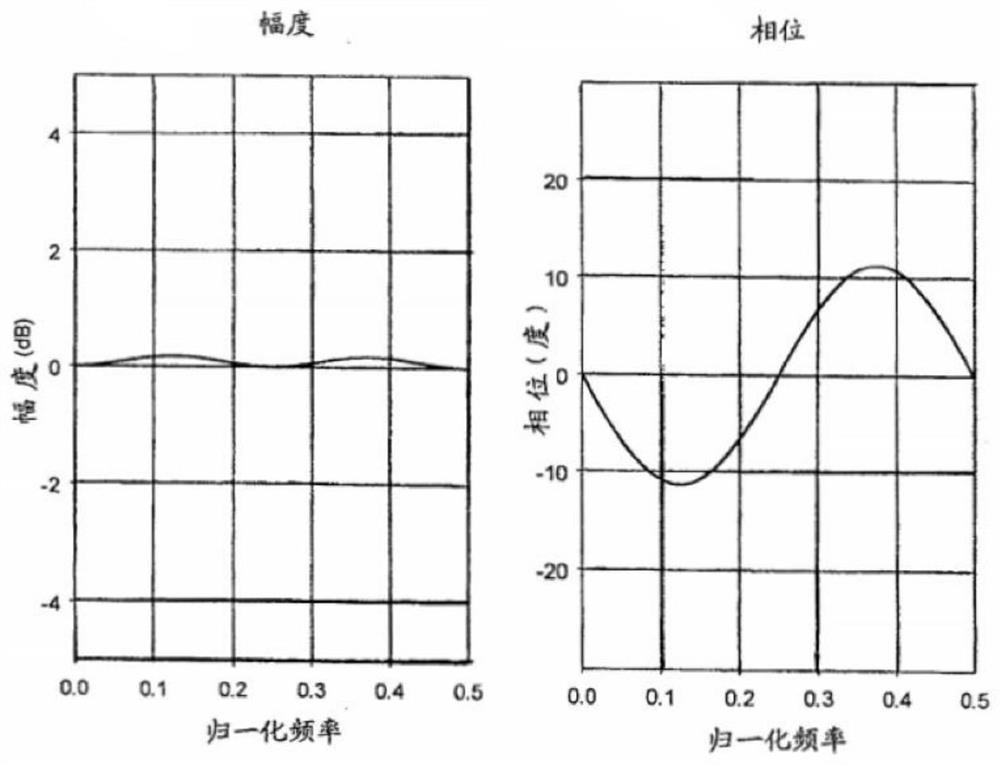

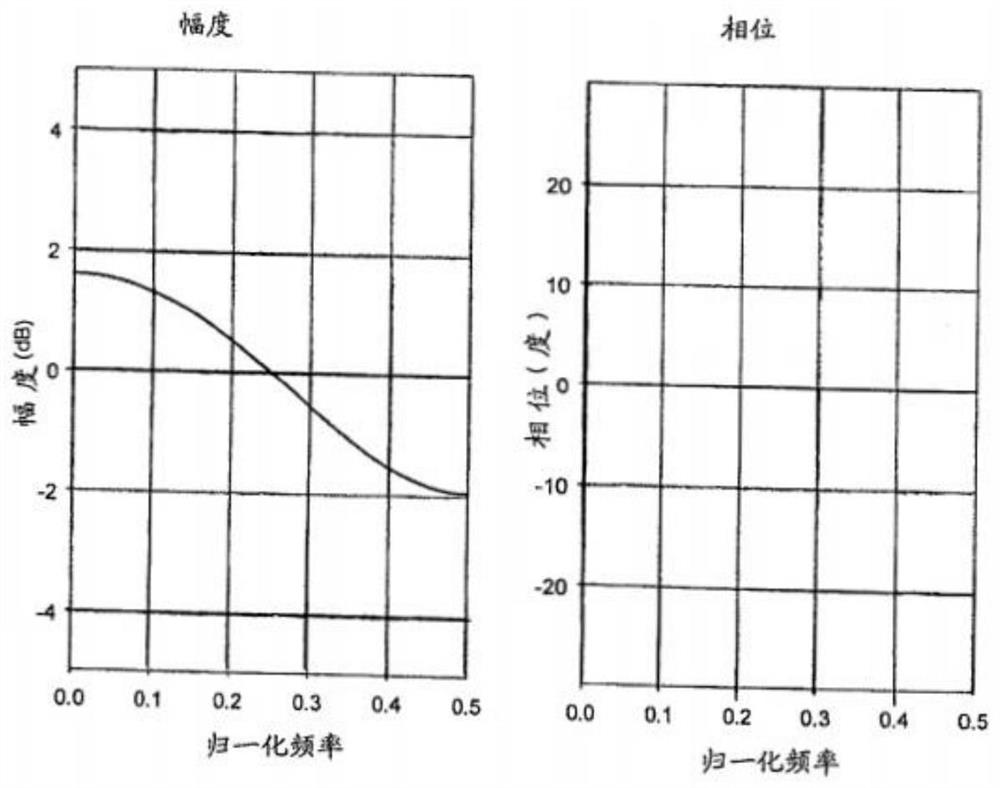

[0044] On the basis of the previous embodiment, the operating parameters include: the amplitude, phase and frequency of infrared waves radiated by the array unit during operation.

Embodiment 3

[0046] On the basis of the previous embodiment, in the step 2, the fusion model is represented by the following formula: Among them, N is the number of array units in the mini LED array, A i The amplitude of the infrared wave radiated by each array element, W i is the phase of the infrared wave radiated by each array element, f i is the frequency of the infrared wave radiated by each array unit, η is the fusion correction function, which is a set arbitrary quadratic function; S is the obtained fusion parameter.

[0047] Specifically, with the increasing complexity of the system, it is obvious that relying on a single sensor to monitor physical quantities has many limitations. Therefore, in the fault diagnosis system, multi-sensor technology is used to monitor various characteristic quantities (such as vibration, temperature, pressure, flow, etc.), and the information of these sensors is fused to improve the accuracy and reliability of fault location. In addition, manual ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com