A thin-walled rubber tube fracturing device

A rubber tube and thin-walled technology, which is applied in the direction of earthwork drilling, discharge machinery, etc., can solve the problems of short operation time, small rupture radius, long time, etc., and achieve safe and reliable operation process, suppress combustion, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

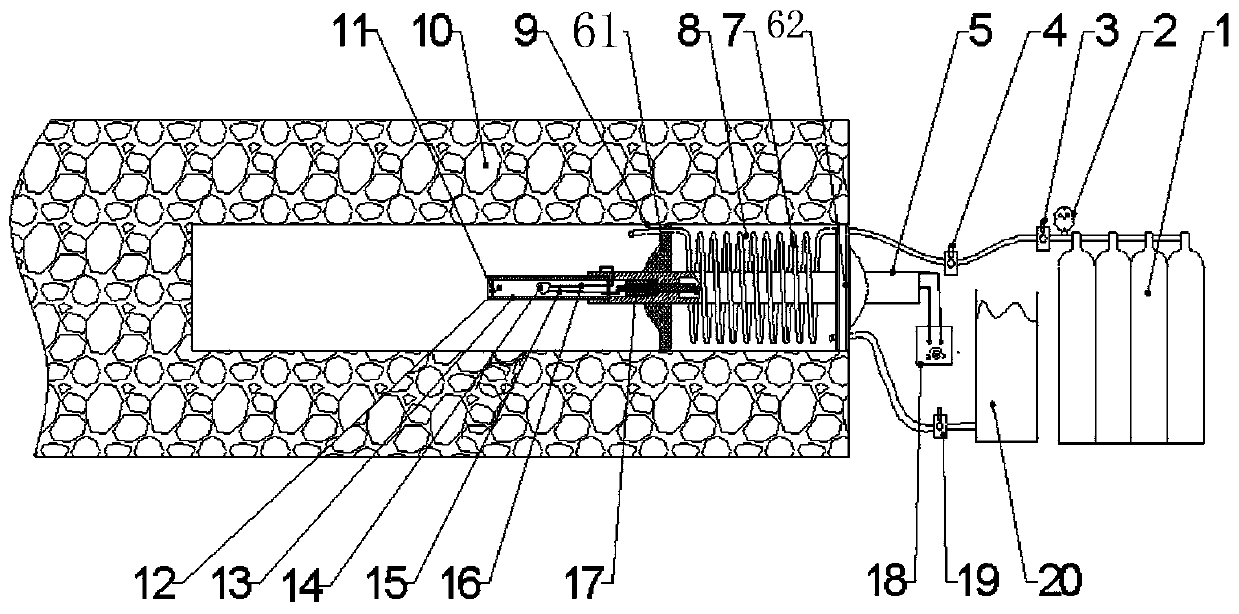

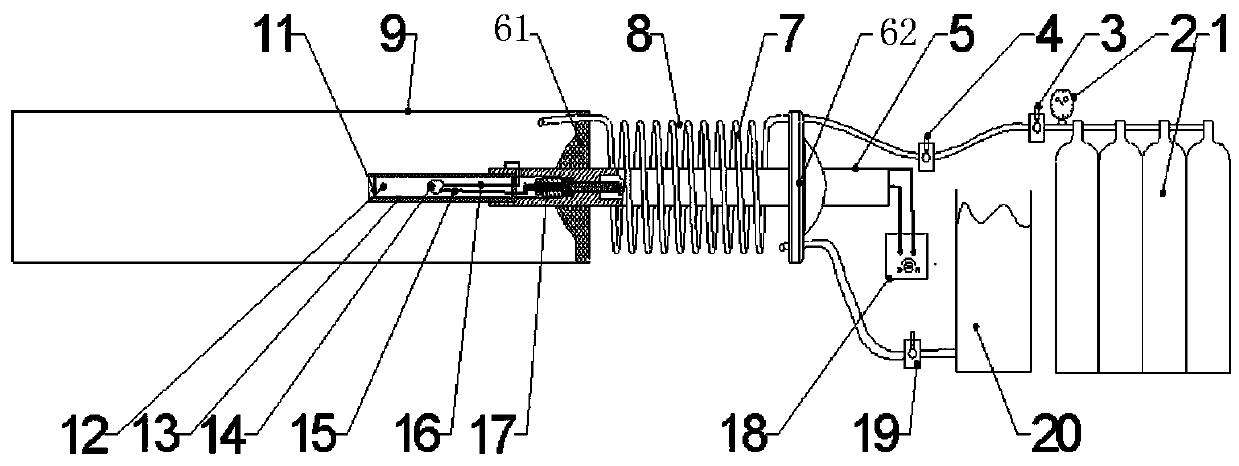

[0013] The present invention will be further described in conjunction with the accompanying drawings.

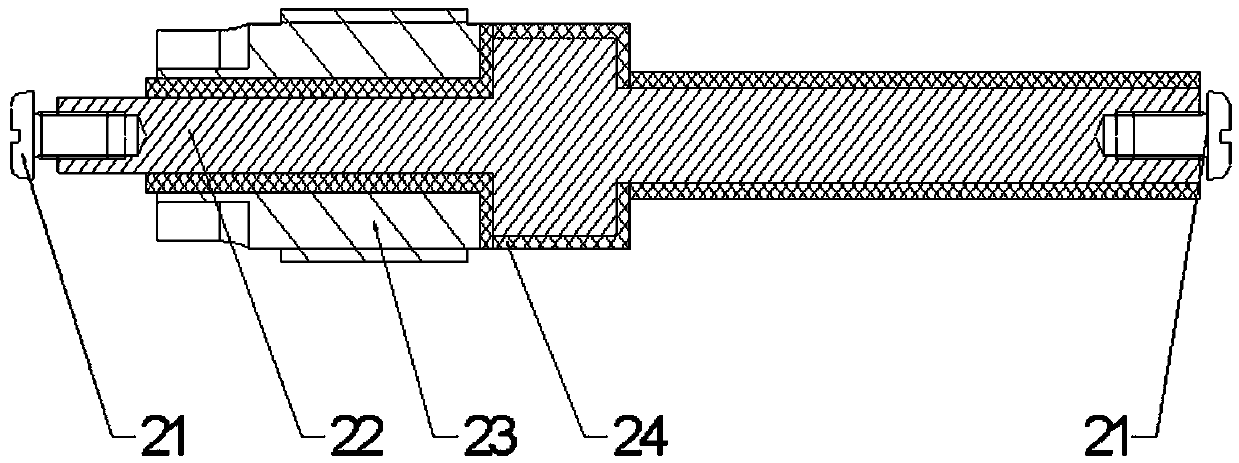

[0014] A thin-walled rubber tube fracturing device including liquid CO 2 Gas cylinder 1, support cylinder 5, first rubber sealing plug 61, second rubber sealing plug 62, gas pipe 7, thin-walled rubber tube 9, heating agent sealing sheet 11, heating agent 12, heating agent cylinder 13, ignition head 14. Electrode assembly 17, detonator 18 and water tank 20.

[0015] Liquid CO 2 Gas cylinder 1 is connected with gas cylinder pressure gauge 2 and high-pressure gas cylinder control valve 3 through a high-pressure hose. 7 on.

[0016] The trachea 7 is a metal helical tube. The air pipe 7 is installed between the first rubber sealing plug 61 and the second rubber sealing plug 62. One end of the air pipe 7 is connected to the air pipe control valve 4, and the other end enters the thin-walled rubber pipe 9 through the first rubber sealing plug 61. middle.

[0017] The first rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com