Cut tobacco moisture constant control method and system based on environmental humidity influence analysis

A technology of impact analysis and environmental humidity, which is applied in the field of tobacco, can solve problems affecting the quality of cigarettes, the difficulty of rolling shredded cigarettes, and affecting the taste of cigarettes, and achieve the effect of accurately predicting the number of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

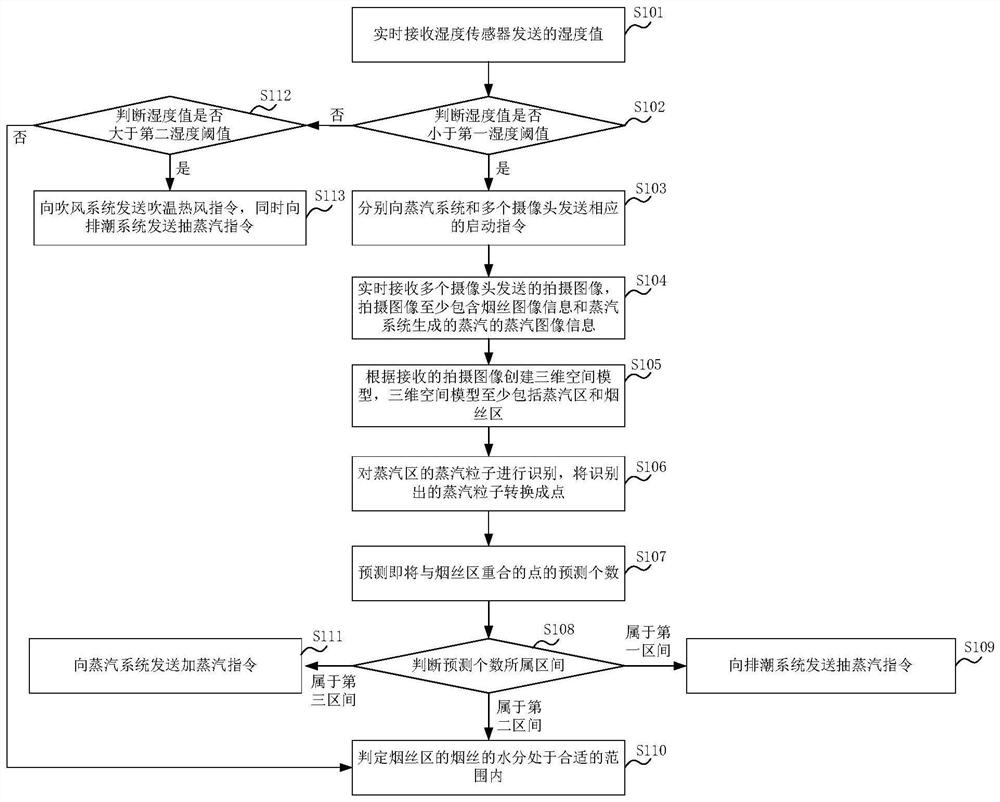

[0060] as attached figure 1 As shown, the present invention is based on the constant control method of shredded tobacco moisture of environmental humidity influence analysis, adopts following steps:

[0061] Step S101: Receive the humidity value sent by the humidity sensor in real time;

[0062] In this embodiment, shredded tobacco is placed in a closed space. For example, a platform is provided in the closed space, and the shredded tobacco is piled up on the platform. The humidity sensor detects and sends the humidity value of the shredded tobacco in real time, and receives the humidity value sent by the humidity sensor in real time. The humidity value detected by the sensor is the existing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com