Three-dimensional measurement system and method for surface of reflective object and storage medium

A technology for surface and three-dimensional measurement of objects, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of small measurement range of deflection systems, and achieve the effects of increased complexity, strong universality and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

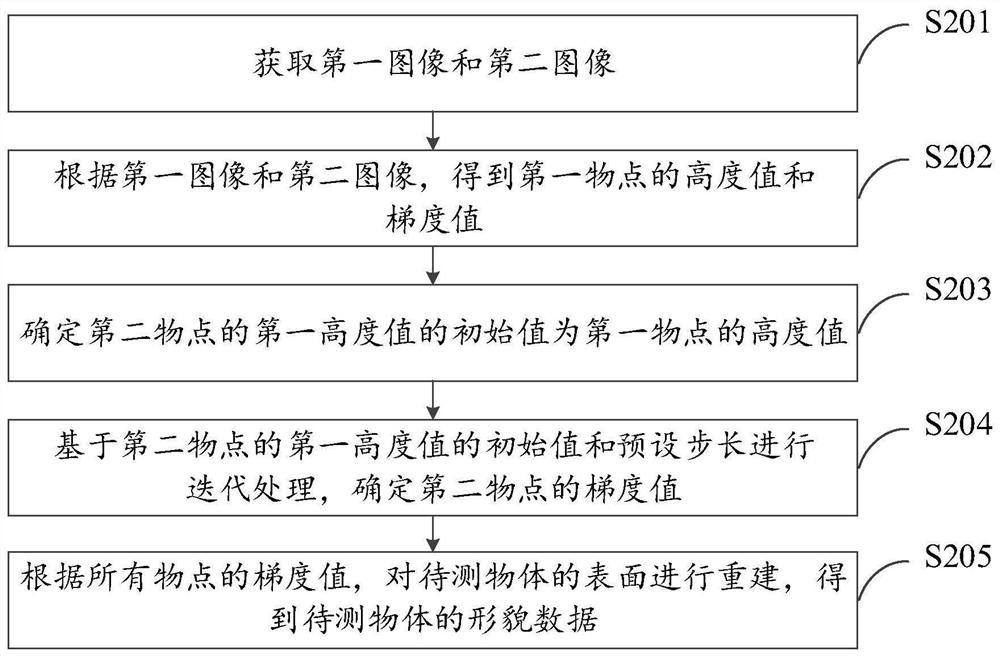

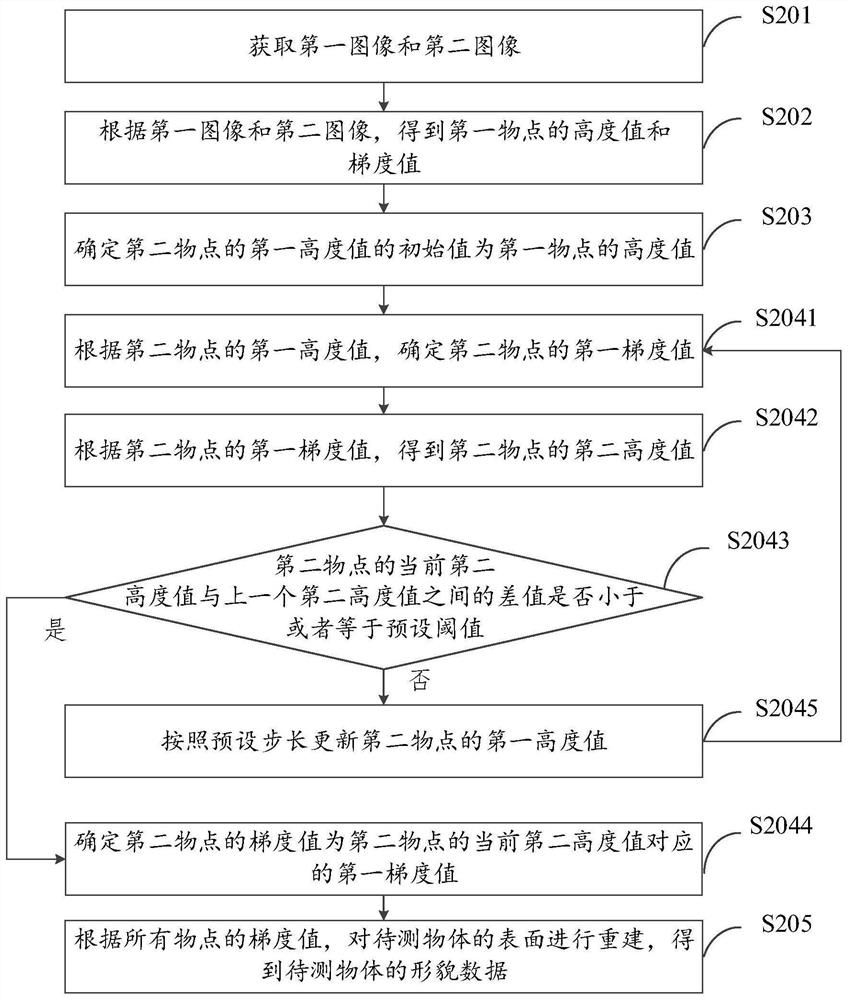

[0072] See figure 2 , figure 2 It is a schematic flowchart of a three-dimensional measurement method for the surface of a reflective object provided in the embodiment of the present application. The method in this embodiment is executed by an electronic device, and the electronic device may be the above-mentioned figure 1 Processing device 4 in the system shown. The first camera in this embodiment can be the above-mentioned figure 1 The first camera 2 shown, the second camera can be the above figure 1 As shown by the second camera 3, the fringe image can be as above figure 1 The fringe image produced by the display device 1 is shown. The method provided in this embodiment includes the following steps:

[0073] S201: Acquire a first image and a second image.

[0074] Wherein, the first image is the image of the object to be measured taken by the first camera, the second image is the image of the object to be measured taken by the second camera, and both the first image ...

Embodiment 2

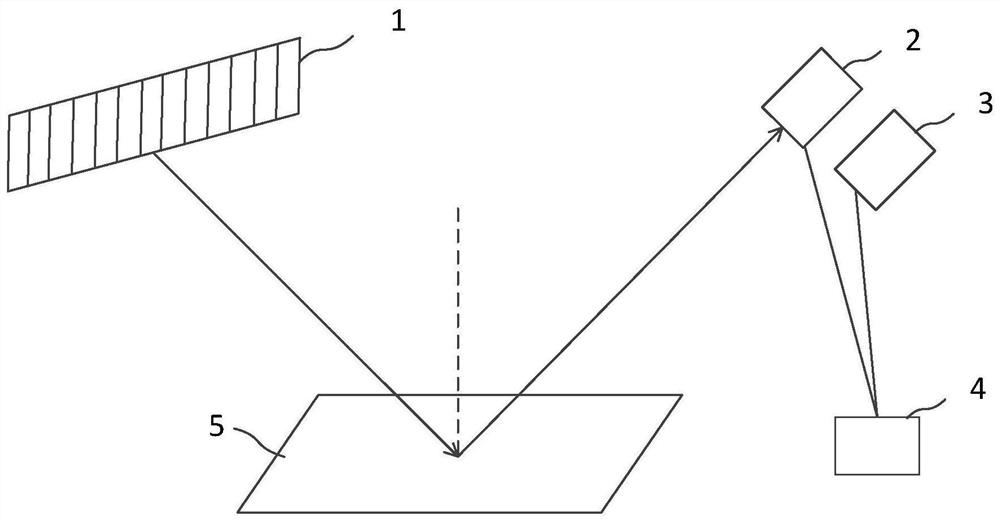

[0169] This embodiment provides a three-dimensional measurement system for the surface of a reflective object, including:

[0170] A display screen for displaying the fringe image;

[0171] The first camera is used to take the first image of the fringe image reflected by the surface of the object to be measured, and send the first image to the processor;

[0172] The second camera is used to take the second image of the fringe image reflected on the surface of the object to be measured, and send the second image to the processor; the field of view of the first camera and the second camera has an overlapping area, and when the object to be measured is measured, The object to be measured is at least partially in the overlapping area;

[0173] The processor is configured to obtain the height value and the gradient value of the first object point according to the first image and the second image, and the first object point is an object point in the overlapping area of the field...

Embodiment 3

[0183] An embodiment of the present application provides a computer-readable storage medium, on which a program is stored, and the program can be executed by a processor to implement the method in the first embodiment above.

[0184] Those skilled in the art can understand that all or part of the functions of the various methods in the foregoing implementation manners can be realized by means of hardware, or by means of computer programs. When all or part of the functions in the above embodiments are implemented by means of a computer program, the program can be stored in a computer-readable storage medium, and the storage medium can include: read-only memory, random access memory, magnetic disk, optical disk, hard disk, etc., through The computer executes the program to realize the above-mentioned functions. For example, the program is stored in the memory of the device, and when the processor executes the program in the memory, all or part of the above-mentioned functions ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com