Dyeing device for textile coarse cloth and using method thereof

A dyeing device and textile technology, which is applied in the direction of processing textile material equipment configuration, textile material processing, and textile material drum processing, to achieve the effects of improving penetration, improving dyeing efficiency, and preventing uneven dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

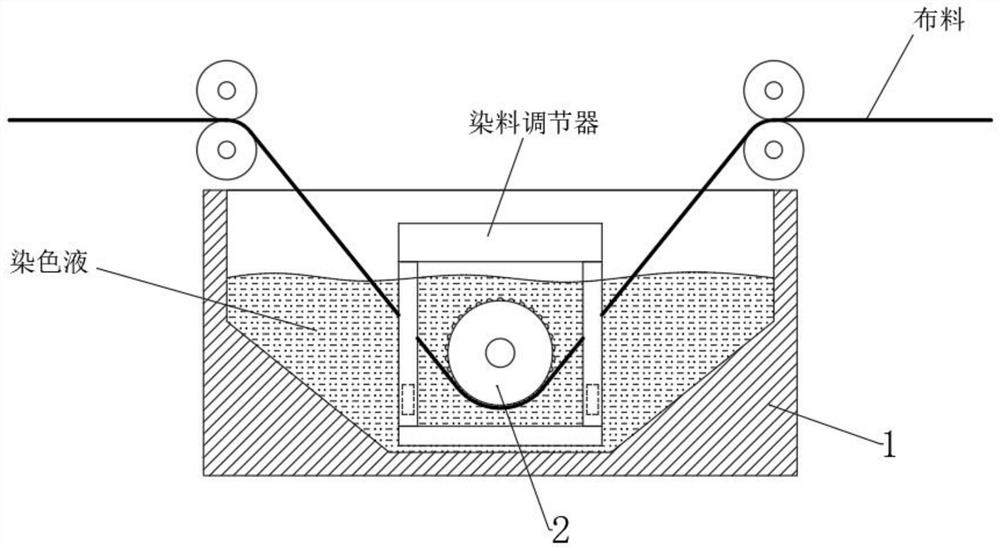

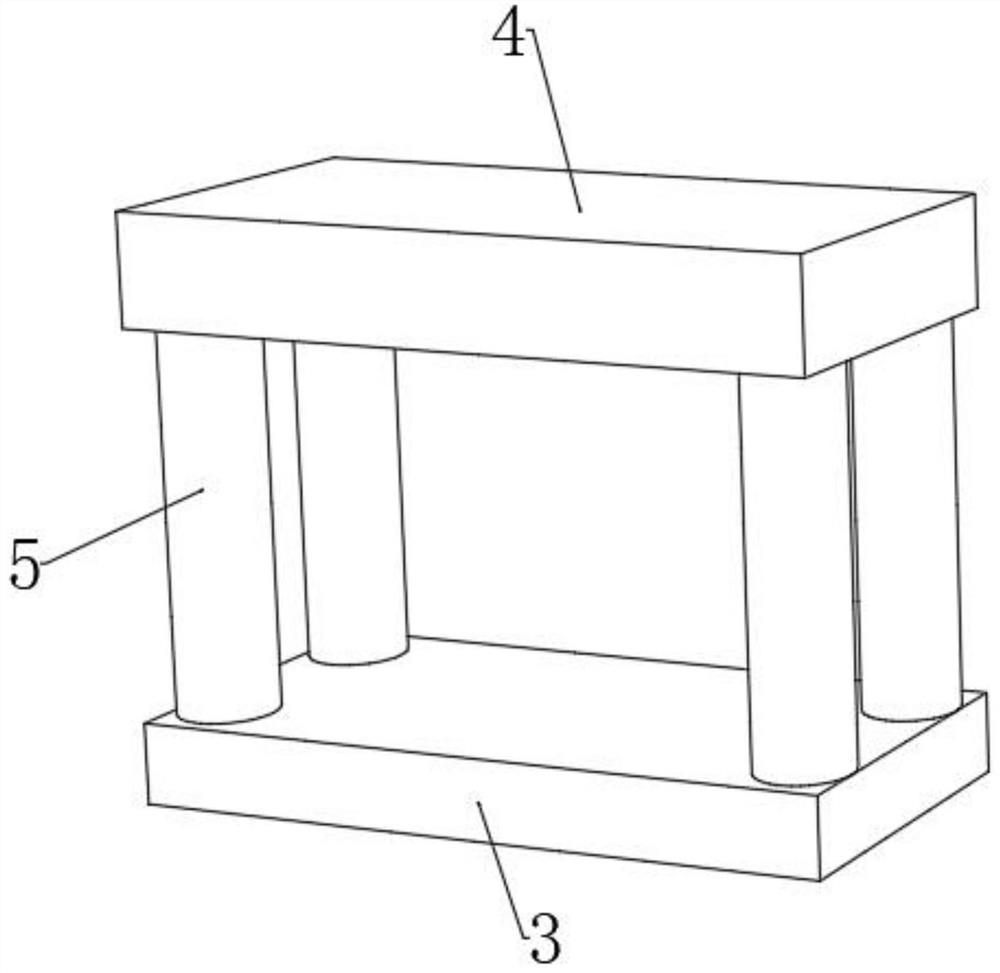

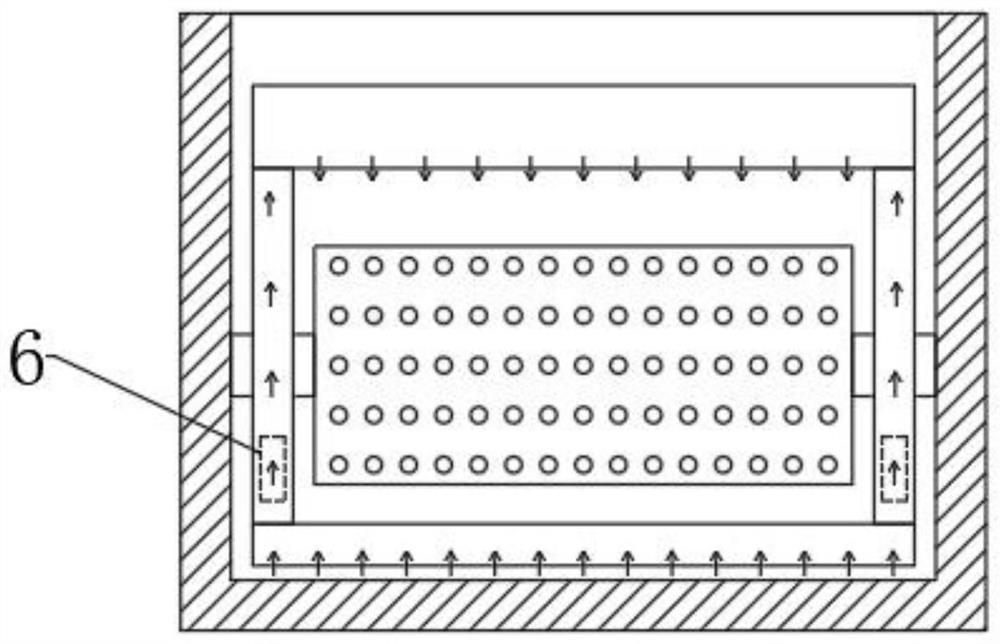

[0046] see Figure 1-8 , a dyeing device for textile coarse cloth, including dyeing vat 1, please refer to figure 1 , 6 The inner wall of the dyeing vat 1 is rotatably connected with a roller 2, and the roller 2 is wound with cloth, and the side wall of the roller 2 is fixedly connected with a plurality of evenly arranged perforated balls 201, the perforated balls 201 include a spherical membrane 2011, The side wall of the spherical membrane 2011 is fixedly connected with a plurality of needles 2012 arranged at equal intervals. The needles 2012 pierce small holes in the cloth to increase the penetration of the dyeing solution and effectively improve the dyeing effect. The spherical membrane 2011 is a hollow structure, and the spherical membrane 2011 The interior of the dyeing vat 1 is filled with elastic polyurethane 2013. The elastic polyurethane 2013 makes the perforating ball 201 elastic, so as to prevent the needle 2012 from hindering the movement of the cloth. The inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com