Activated sludge culture control equipment

A technology for controlling equipment and activated sludge, applied in water treatment parameter control, water/sludge/sewage treatment, biological water/sewage treatment, etc. Solve the problems of high mud content, achieve the effect of intelligent automatic mud discharge, reduce maintenance expenditure, and deal with large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description in conjunction with the accompanying drawings and specific embodiments of the present invention is described in further detail.

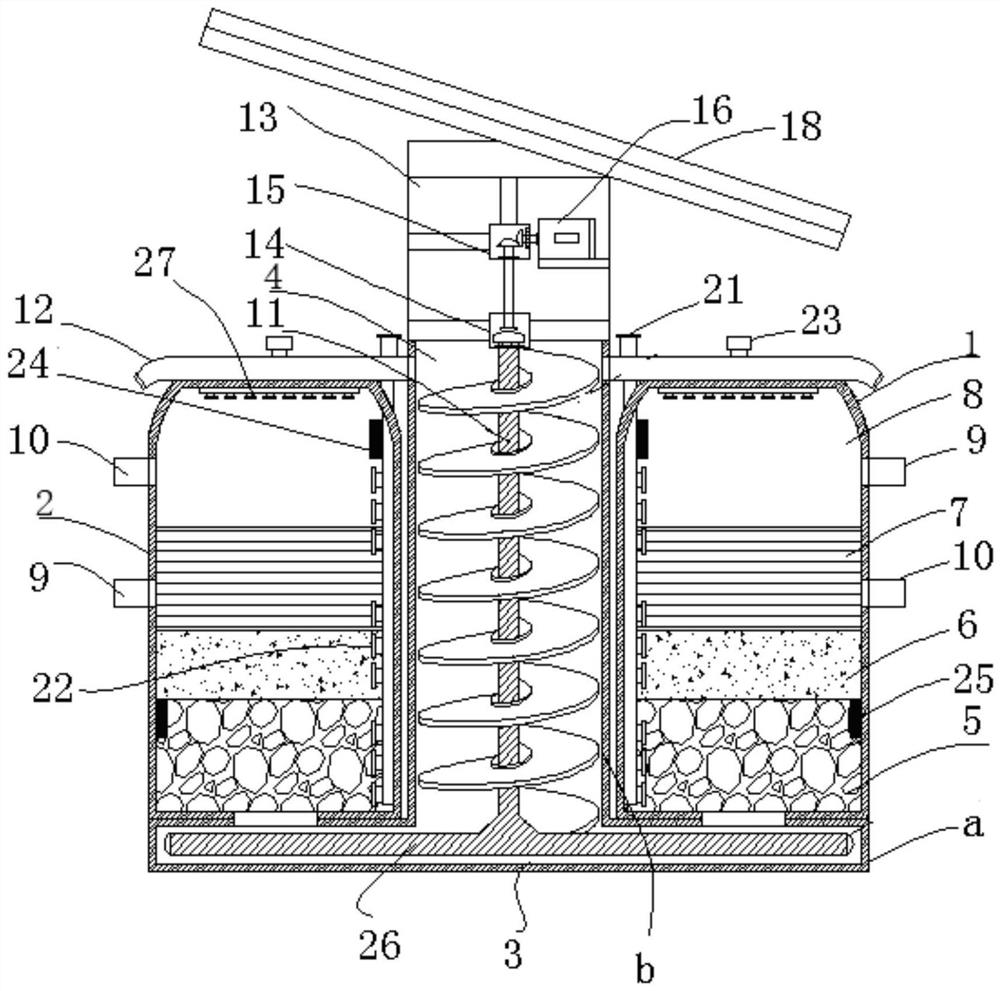

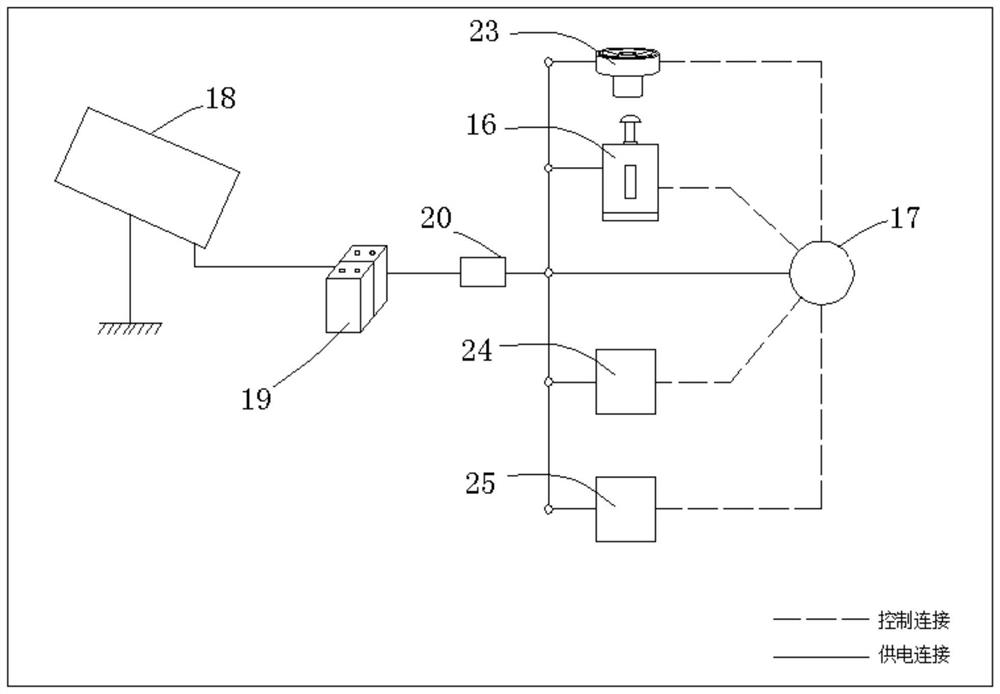

[0025] like figure 1 , The activated sludge in the control device of the present embodiment includes a first waste water treatment tank 1, second tank 2 sewage treatment, sludge collection tank 3, the mud and the mud tank 4 means 4 provided in a clay pot above the sludge collection tank 3 and the mud tank 3 communicates with the bottom of the sludge collection tank 4, a first sewage tank 1, a second water treatment tank 2 is divided into both sides in the mud tank 4, and the first sewage treatment 1 tank, a second water treatment tank 2 are communicated with sludge collection tank 3, a first sewage treatment tank provided with a bottom from the bottom sediment layer 5, layer 6 within a colloidal suspension, mixed layer 7 and the top layer clarification 8, a wastewater treatment tank 1 is provided in the mixed layer 7 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com