Cylindrical lithium battery module assembly production line

A lithium battery and production line technology, which is applied in the field of cylindrical lithium battery module assembly production line, can solve the problems of large personnel investment, high operating difficulty for operators, and many manual operation stations, so as to achieve a high degree of automation, enhance the competitiveness of enterprises, The effect of reducing operating stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0042] Please refer to Figure 1-24 , the embodiment of the present invention includes:

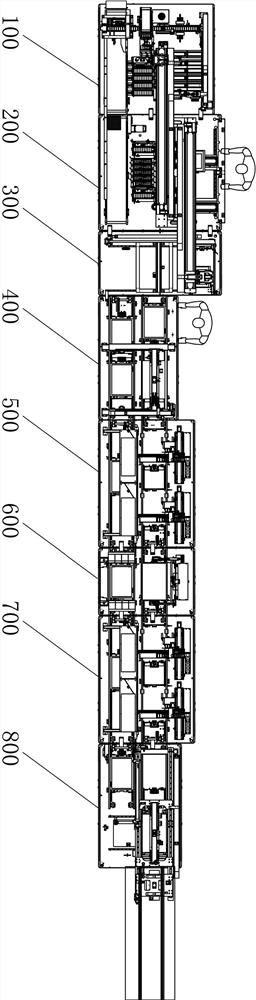

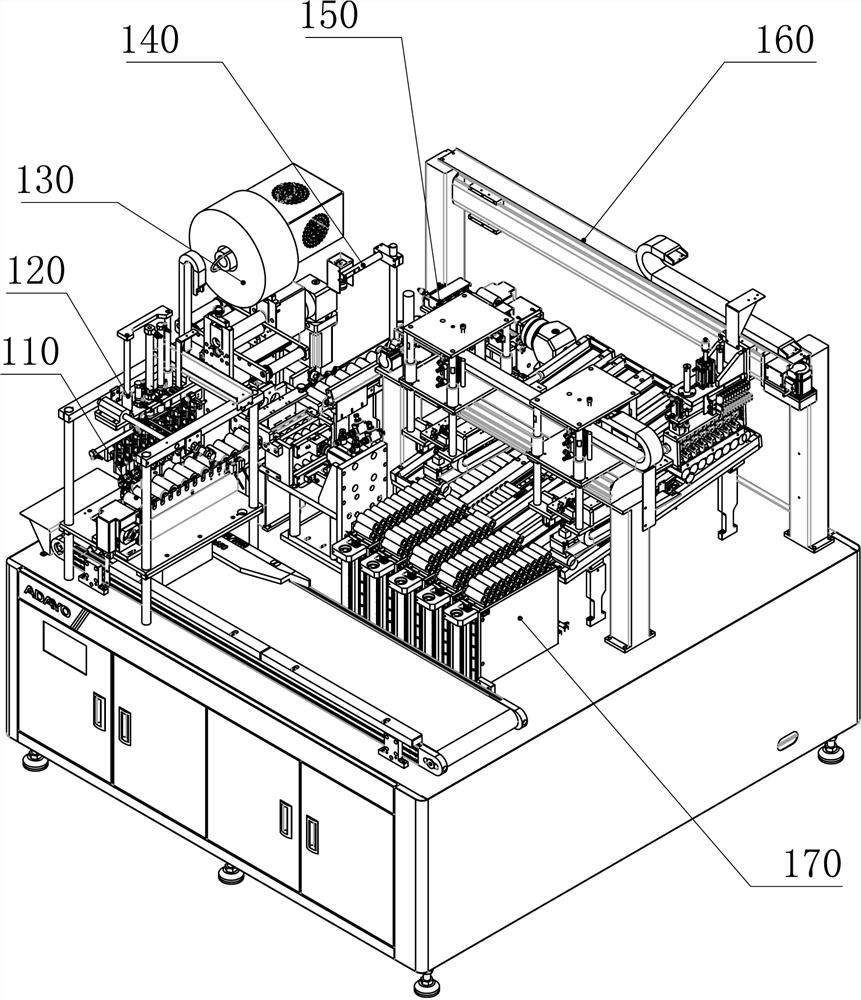

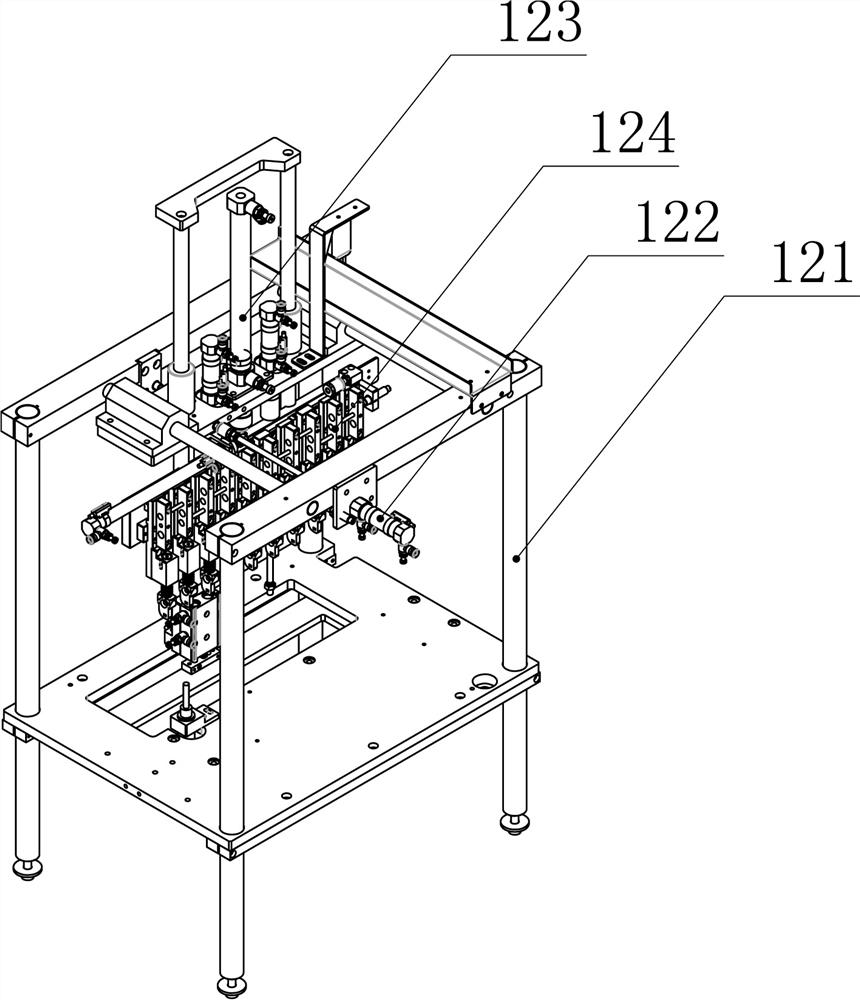

[0043] The schematic diagram of the whole line layout of the technology of the present invention is attached figure 1 , including the following equipment: a cell sorting device 100 for sorting cells, a cell insertion bracket device 200 for inserting cells into the lower bracket, a polarity inspection device 300 for detecting the positive and negative poles of cells, The jig closing equipment 400 for fastening the upper bracket and the lower bracket, the spot welding equipment A500 on one side of the welding product, the turning equipment 600 for flipping the product, the spot welding equipment B700 on the other side of the welding product, and the bottom of the product Material e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com