Silicon-carbon negative electrode material adhesive as well as preparation method and application thereof

A negative electrode material and binder technology, applied in the field of silicon carbon negative electrode material binder and its preparation, to achieve the effect of improving processability, improving cycle stability, and reducing gas production problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned device is a traditional radical polymerization method, comprising the following steps:

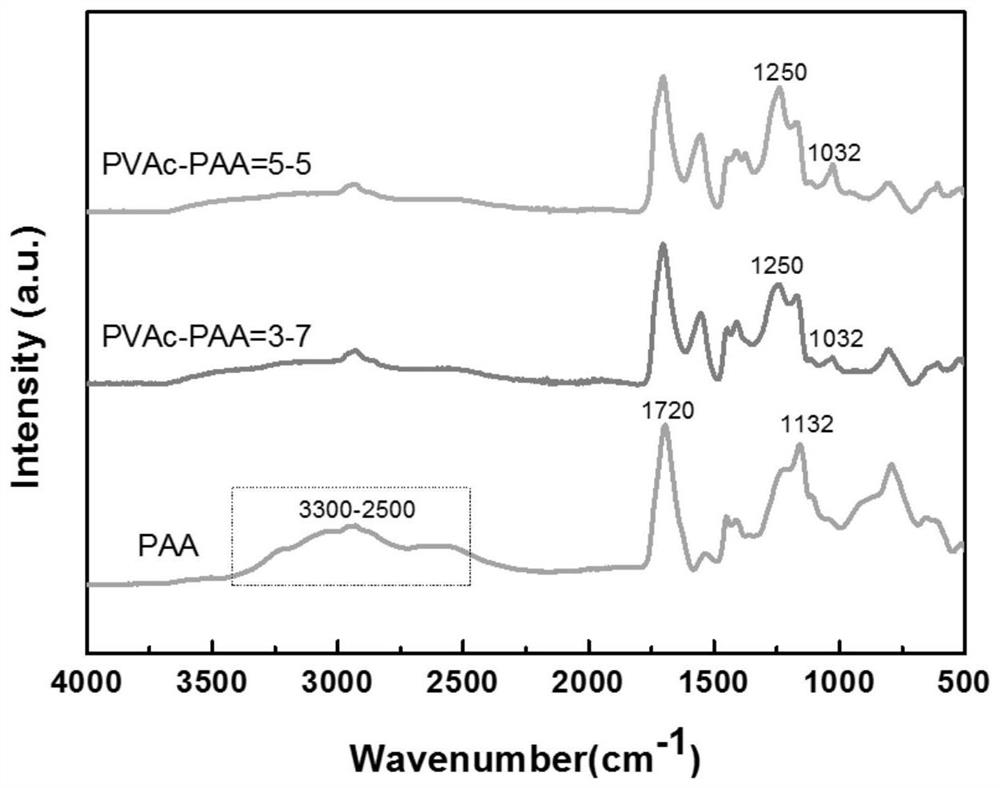

[0036] Step 1, preparation of polyvinyl acetate-co-polyacrylic acid (PVAc-co-PAA) precursor solution: add polyvinyl alcohol and emulsifier to water in turn, heat to dissolve them all, polyvinyl alcohol molecular weight is less than 100000, preferred polyvinyl alcohol The molecular weight of vinyl alcohol is 31000, the emulsifier is OP-10, the heating temperature is 80-90°C, the heating time is 20-40min, and the solution A is obtained after cooling for later use; since vinyl acetate has high solubility in water and is easy to hydrolyze, The generated acetic acid will interfere with the polymerization; at the same time, the vinyl acetate free radical is very active and the chain transfer reaction is significant, so polyvinyl alcohol will be added for protection. The purpose of adding emulsifier is to make vinyl acetate better dispersed und...

Embodiment 1

[0048] (1) Dissolve 0.2g of polyvinyl alcohol and 0.2g of OP-10 in water, heat at 85°C for 30min to dissolve the above substances, and cool down for later use to obtain solution A.

[0049] (2) Dissolve 2.8g of acrylic acid, 0.4g of lithium hydroxide monohydrate, and 1.2g of vinyl acetate in solution A in sequence to form reaction system B, remove oxygen from reaction system B by bubbling for 30 minutes, and finally add 0.04g of ammonium persulfate was used as an initiator, and the monomer concentration was 20%wt. After reacting at 75° C. for 30 minutes, a copolymer solution C was obtained and kept for future use.

[0050] (3) Synthesis of polyvinyl acetate-co-lithium polyacrylate-co-polyacrylic acid (PVAc-co-PAALi-co-PAA), add 0.8g lithium hydroxide monohydrate to copolymer C, and add water to make the concentration From 20%wt to 10%wt, the reaction temperature is 60°C, and the reaction time is 60min. After the reaction, polyvinyl acetate-polyacrylate lithium-polyacrylic acid...

Embodiment 2

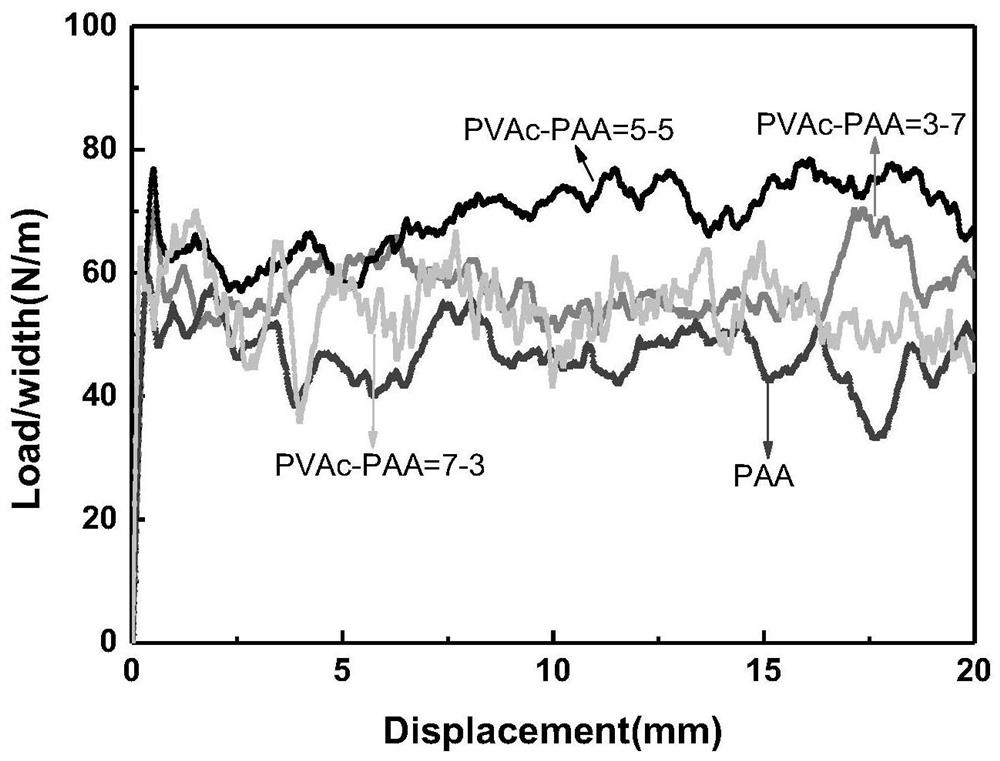

[0053] The preparation method and reaction conditions of polyvinyl acetate-co-lithium polyacrylate-co-polyacrylic acid copolymer are the same as in Example 1, and the feed ratio is polyvinyl alcohol, emulsifier, acrylic acid, total lithium hydroxide monohydrate, vinyl acetate The mixing ratio of the ester and the initiator is 5:5:50:37.5:50:1, and the mass ratio of the three blocks is vinyl acetate: lithium acrylate: acrylic acid = 50:37.5:12.5 to complete the adhesive A2 preparation.

[0054] The binder A2 was used to prepare silicon carbon negative electrodes for lithium-ion batteries according to the above method and assembled into lithium-ion batteries to test their performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com