Formaldehyde detection test paper based on nano-composite fiber and preparation method and application thereof

A nano-composite fiber and detection test paper technology, which can be used in measurement devices, analysis by chemical reaction of materials, and material analysis by observing the influence of chemical indicators, etc. Problems such as expensive operation to achieve improved detection limit and accuracy, excellent hydrophilicity and water absorption, and excellent color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 0.1 g of fumed hydrophilic silica into 18.7 g of 99.8% N, N-dimethylformamide with a mass fraction of 99.8% and sonicate for 1 hour at room temperature.

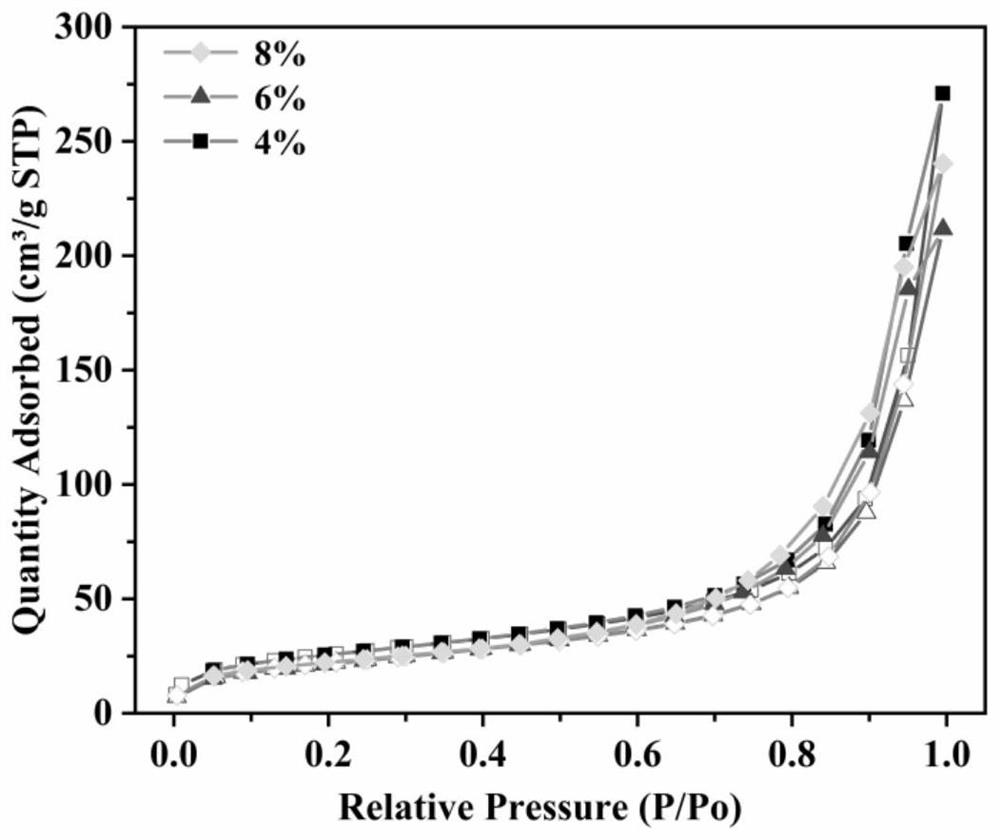

[0039] (2) At room temperature, 1.2g polyacrylonitrile (average molecular weight 150000) was dissolved in 18.8gN, 1000 revs per minute in the mixed solution of N-dimethylformamide and silicon dioxide, stirred for 8 hours, and the mass fraction obtained was 0.5% fumed hydrophilic silica in 6% polyacrylonitrile spinning dope.

[0040] (3) Under the condition that the relative humidity of the room temperature is 40%, the spinning dope is electrospun with a boost speed of 1.2 ml per hour and the needle is connected to a high voltage of 10,000 volts. The receiving device is aluminum foil, and the needle and the receiving drum are The distance between them was 15 cm, and a polyacrylonitrile nanofiber film composited with nanoparticles was obtained. The fiber membrane was dried in a vacuum oven at 0.1 degree of vacu...

Embodiment 2

[0045] The mass of gas-phase hydrophilic silica in step (1) in Example 1 was set to 0.2 g, and the mass of N,N-dimethylformamide was set to 18.6 g.

[0046] In the step (2) of Example 1, a 6% polyacrylonitrile spinning stock solution with a mass fraction of 1% fumed hydrophilic silica was obtained.

[0047] Steps (3)(4)(5) are all unchanged.

[0048]At room temperature, place the test paper in an environment containing different concentrations of formaldehyde gas for 30 minutes, the test paper will turn from yellow to pink and pink in sequence, and then use a high-sensitivity UV-visible spectrophotometer to measure the absorbance. The change of the characteristic peak absorbance value before and after the gas is used to judge the degree of reaction. Repeating the above steps shows that the detection range is 25ppb-5ppm, the variation range of the characteristic peak absorbance value is about Δu=0.55, and the specific surface area of the test paper is 80.05 square meters per...

Embodiment 3

[0050] The mass of gas-phase hydrophilic silica in step (1) in Example 1 was set to 0.3 g, and the mass of N,N-dimethylformamide was set to 18.5 g.

[0051] In the step (2) of Example 1, a 6% polyacrylonitrile spinning stock solution with a mass fraction of 1.5% gas-phase hydrophilic silica was obtained.

[0052] Steps (3)(4)(5) are all unchanged.

[0053] At room temperature, place the test paper in an environment containing different concentrations of formaldehyde gas for 30 minutes, the test paper will turn from yellow to pink and pink in sequence, and then use a high-sensitivity UV-visible spectrophotometer to measure the absorbance. The change of the characteristic peak absorbance value before and after the gas is used to judge the degree of reaction. Repeating the above steps shows that the detection range is 50ppb-5ppm, the variation range of the characteristic peak absorbance value is about Δu=0.58, and the specific surface area of the test paper is 94.89 square met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com