High ground stress assessment method, system, device and medium

A technology of high in-situ stress and in-situ stress, applied in the direction of applying stable tension/pressure to test the strength of materials, using sonic/ultrasonic/infrasonic waves to analyze solids, measuring devices, etc. High accuracy, high efficiency, and the effect of reducing budget costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

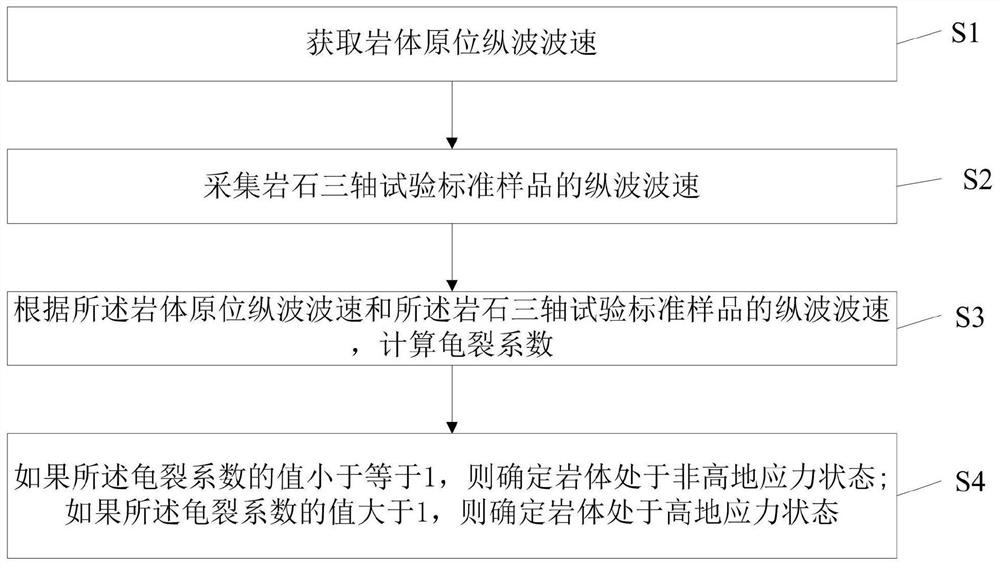

[0047] The sonic testing method is a comprehensive method, which can comprehensively reflect the overall damage condition of the rock mass. The current national standards and internationally recommended methods all use the crack coefficient K as a characterization index of rock mass integrity. K is a value less than 1, and the closer it is to 1, the higher the integrity of the rock mass. However, under the condition of high geostress, excessive confining pressure makes the original fractures of the rock mass highly closed. With the progress of excavation and unloading, the original fractures in the rock mass unload and open and generate new unloading fractures, resulting in Deterioration occurs. Therefore, there will be an abnormal phenomenon in the engineering rock mass in a state of high ground stress. The longitudinal wave velocity of the rock mass tested in situ is greater than that of the rock mass tested in the laboratory, that is, the crack coefficient K>1, which is cal...

Embodiment 2

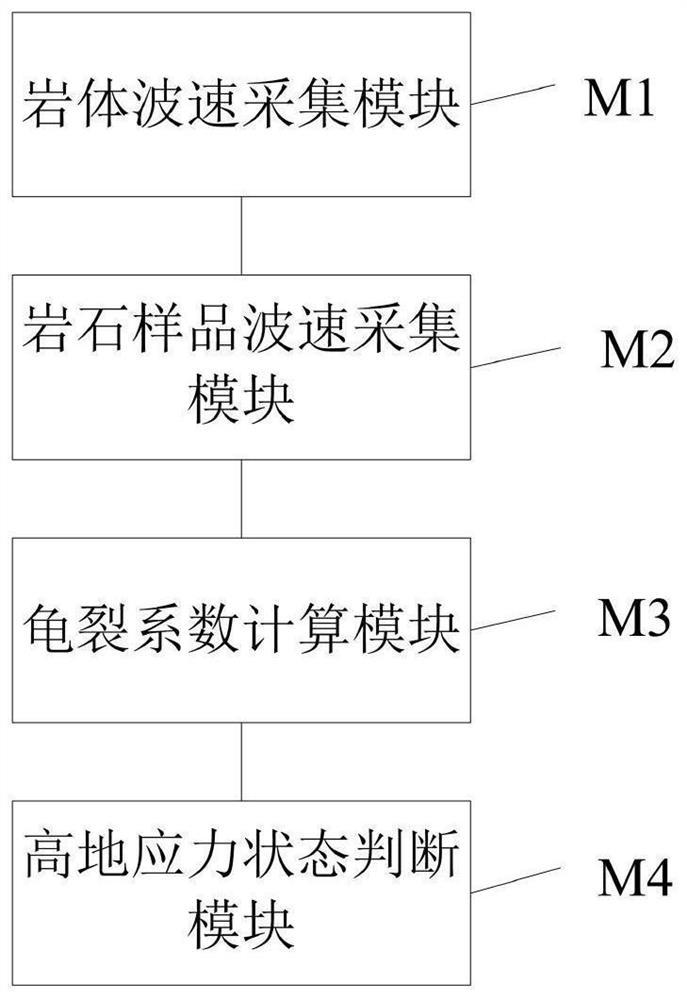

[0061] Such as figure 2 As shown, the present embodiment is used to provide a high ground stress evaluation system, including:

[0062] The rock mass wave velocity acquisition module M1 is used to acquire the in-situ longitudinal wave velocity of the rock mass;

[0063] The rock sample wave velocity acquisition module M2 is used to collect the longitudinal wave velocity of the rock triaxial test standard sample;

[0064] The cracking coefficient calculation module M3 is used to calculate the cracking coefficient according to the in-situ longitudinal wave velocity of the rock mass and the longitudinal wave velocity of the rock triaxial test standard sample;

[0065] The high ground stress state judging module M4 is used to judge the value of the crack coefficient, if the value of the crack coefficient is less than or equal to 1, it is determined that the rock mass is in a non-high ground stress state; if the value of the crack coefficient is greater than 1 , it is determined...

Embodiment 3

[0067] This embodiment is used to provide a kind of high ground stress assessment equipment, comprising:

[0068] processor; and

[0069] a memory in which computer readable program instructions are stored,

[0070] Wherein, the high ground stress assessment method is executed when the computer readable program instructions are executed by the processor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com