Cargo conveying system and cargo conveying method

A technology of conveying system and conveying direction, applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve the problem of low efficiency of cargo transportation, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

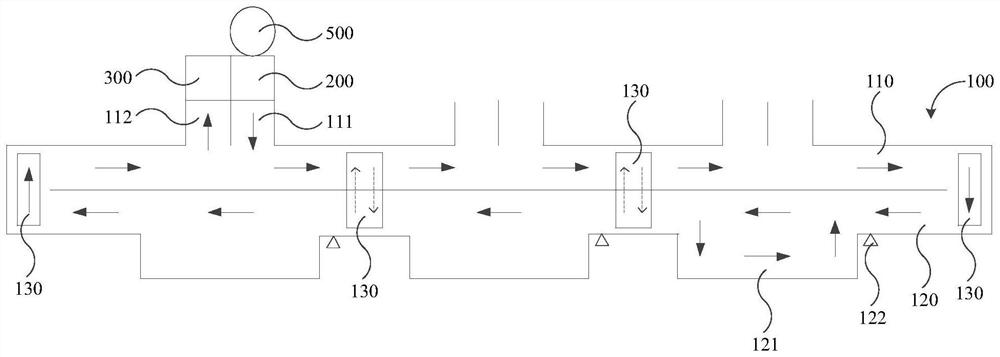

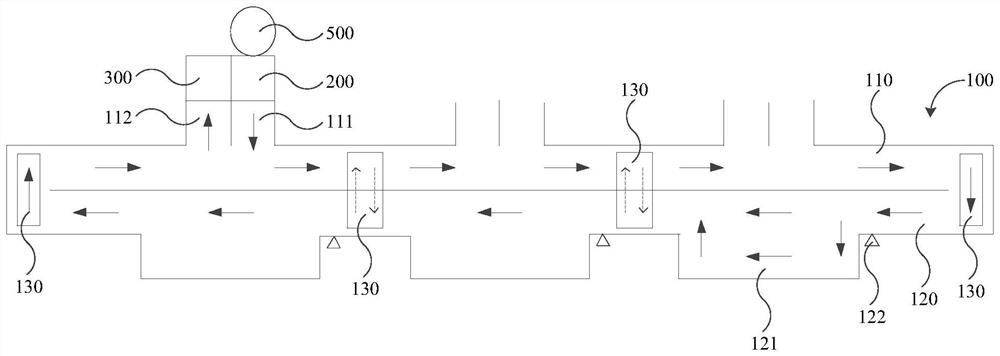

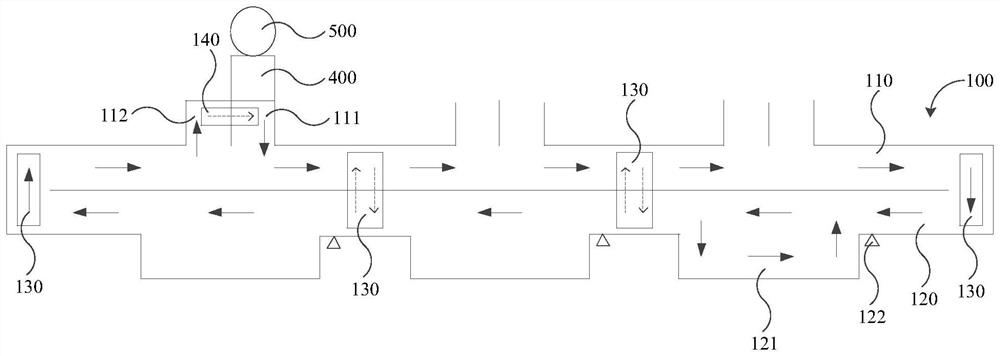

[0074] figure 1 A schematic top view of a cargo conveying system provided by an embodiment of the present disclosure Figure 1 ; figure 2 A schematic top view of a cargo conveying system provided by an embodiment of the present disclosure Figure II ; image 3 A schematic top view of a cargo conveying system provided by an embodiment of the present disclosure Figure three ; Figure 4 Schematic top view of a part of the closed-loop conveyor line and sorting conveyor line provided for the embodiments of the present disclosure Figure 1 ; Figure 5 Schematic top view of a part of the closed-loop conveyor line and sorting conveyor line provided for the embodiments of the present disclosure Figure II ; Figure 6 for in Figure 4 A schematic side view of an auxiliary conveyor line set above the picking conveyor line in ; Figure 7 It is a structural schematic diagram of docking between a handling robot and an unloader provided by an embodiment of the present disclosure. ...

Embodiment 2

[0110] Figure 8 A process flow of a cargo delivery method provided by an embodiment of the present disclosure Figure 1 ; Figure 9 A process flow of a cargo delivery method provided by an embodiment of the present disclosure Figure II ; Figure 10 A process flow of a cargo delivery method provided by an embodiment of the present disclosure Figure three ; Figure 11 A process flow of a cargo delivery method provided by an embodiment of the present disclosure Figure four .

[0111] refer to Figure 8 to Figure 11The embodiment of the present disclosure provides a cargo delivery method, which is applied to the cargo delivery system in Embodiment 1. The components and specific structure of the cargo delivery system involved in this embodiment can refer to the description in Embodiment 1. The execution subject of the goods delivery method may be a management device, which may include a computer, a server, and a chip, etc., and the management device may control the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com