Injection mold convenient to overhaul

A technology for easy maintenance of injection molds, applied in the field of molds, can solve the problems of affecting the demoulding effect, product quality reduction, easy to mix air bubbles, etc., to achieve good demoulding effect, smooth movement, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

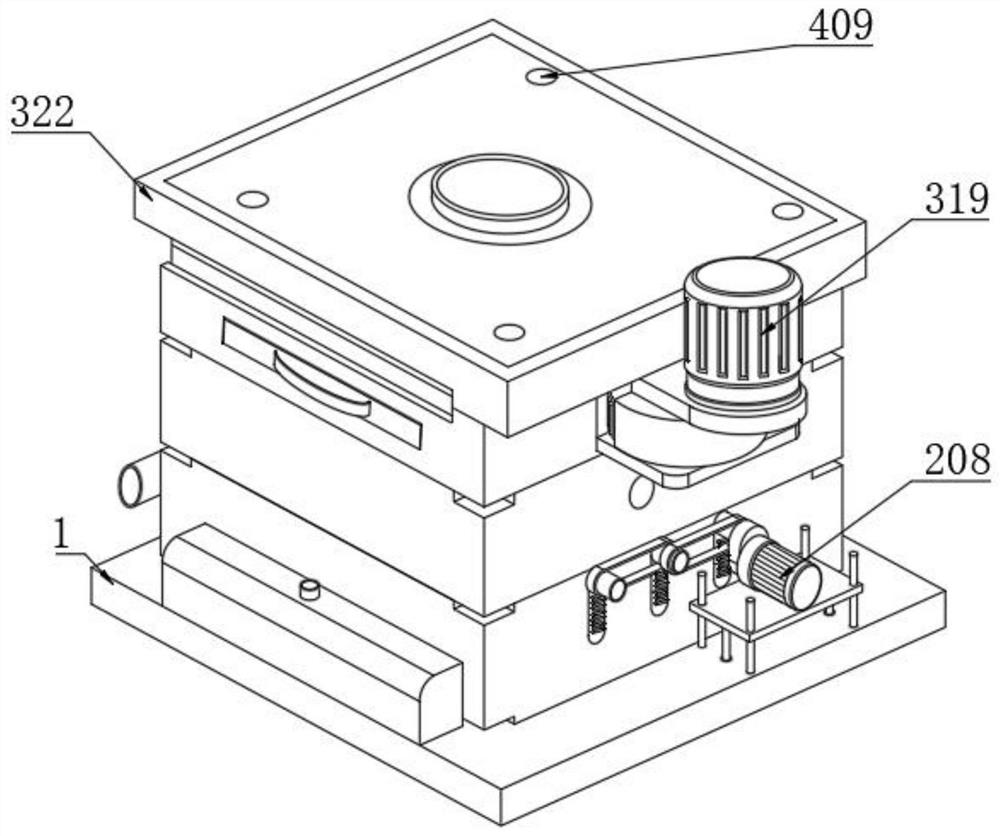

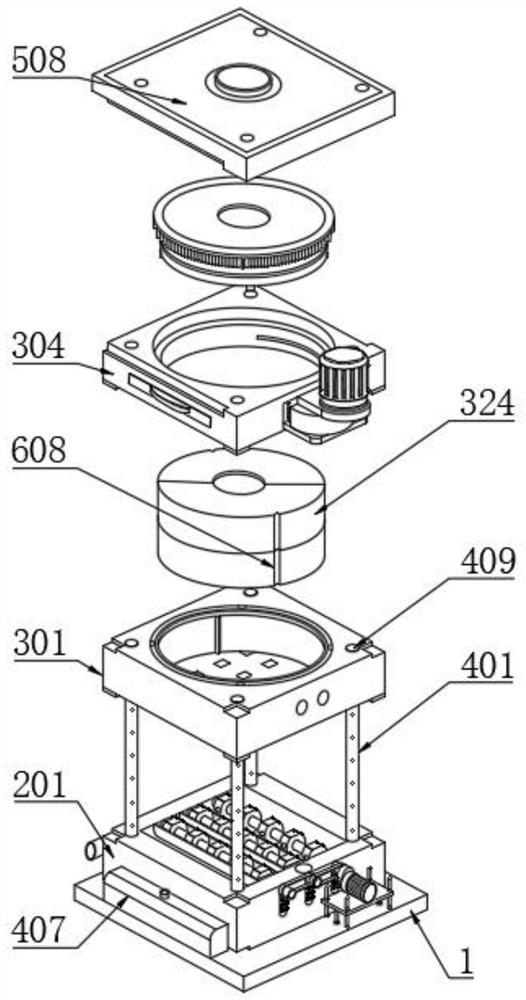

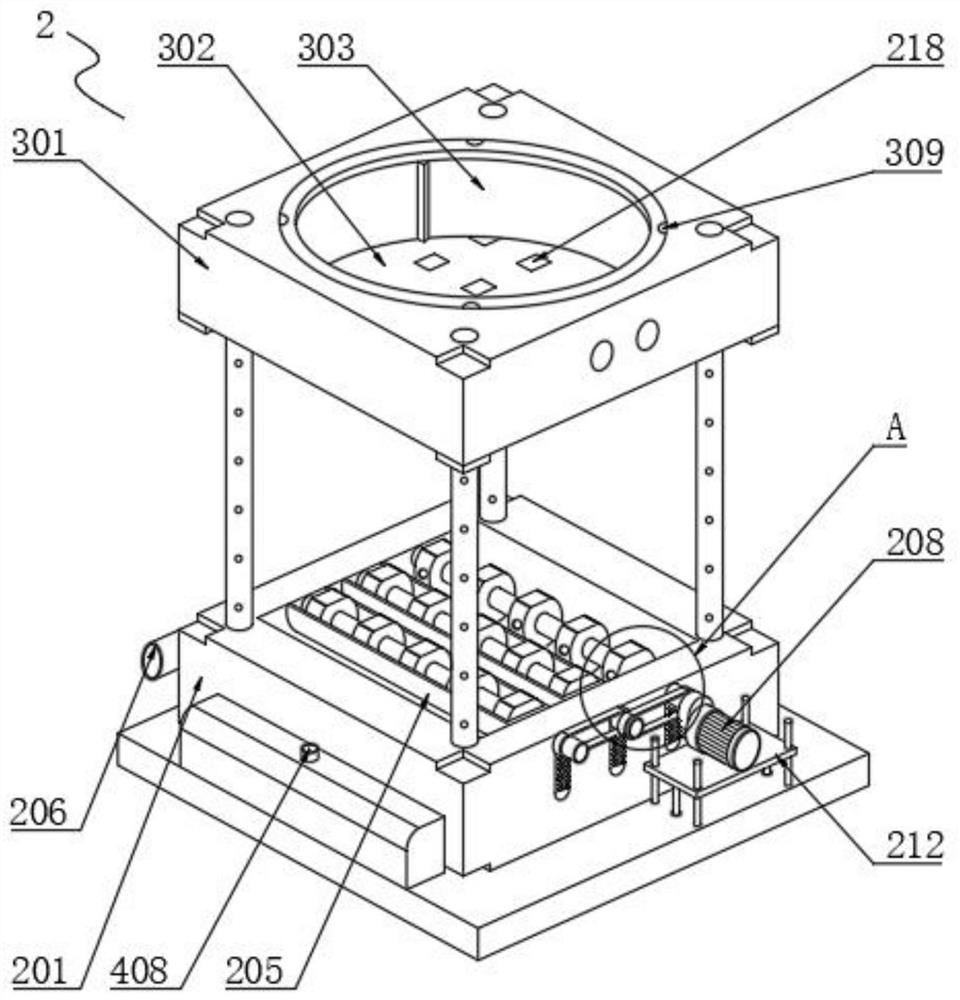

[0049] Example: such as Figure 1-10 As shown, the present invention provides a technical solution for injection molds that is convenient for maintenance, including a bottom plate 1, a damage-resistant demoulding component 2 is installed on the top surface of the bottom plate 1, and a uniform molding component 3 is installed on the top of the damage-resistant demoulding component 2, and the uniform molding component 3 is installed on the top of the bottom plate 1. The molding assembly 3 includes a lower template 301, an embedding cavity 302, a lower rotating ring 303, an upper template 304, a rotating hole 305, a supporting groove 306, a supporting ring 307, an upper rotating cover 308, a docking groove 309, a docking block 310, and a sealing plate groove 311 , clamping hole 312, clamping plate 313, rotating groove 314, sealing plate 315, meshing hole 316, supporting plate 317, gear cover 318, transmission motor 319, driving gear 320, ring gear 321, top plate 322, feed pipe 323...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com