Building reinforcing steel bar synergistic welding device

A technology for building steel bars and welders, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor safety and low efficiency, and achieve the effect of preventing electric shock, protecting workers, and facilitating filling and removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

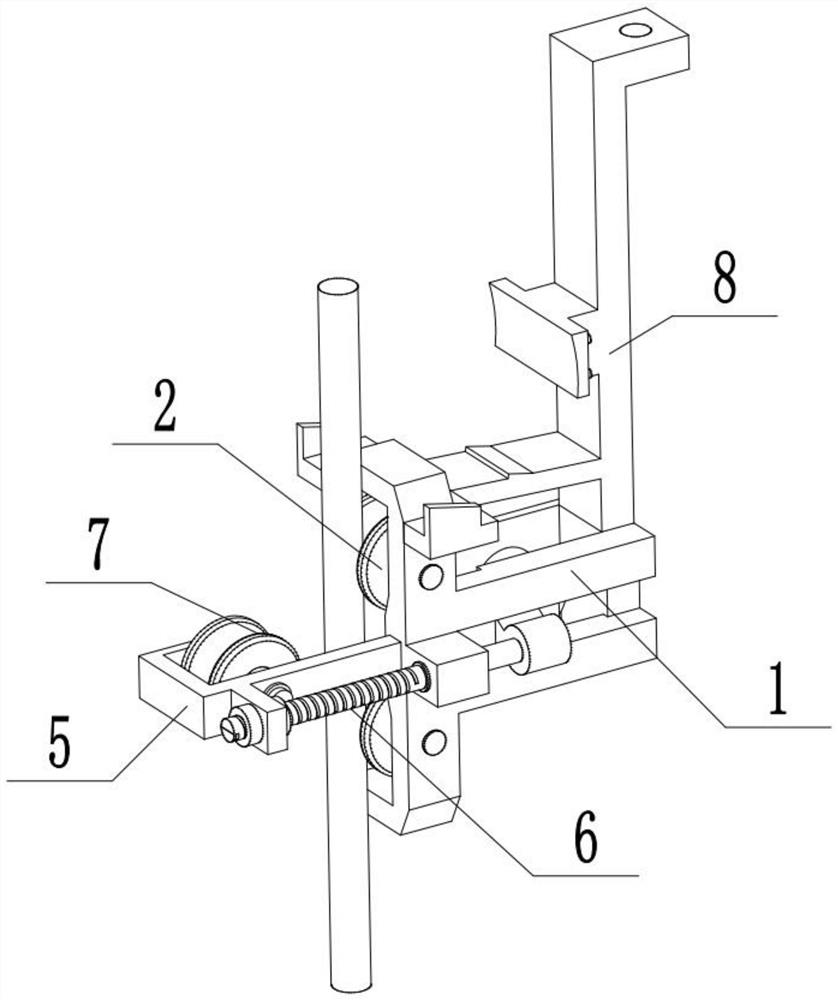

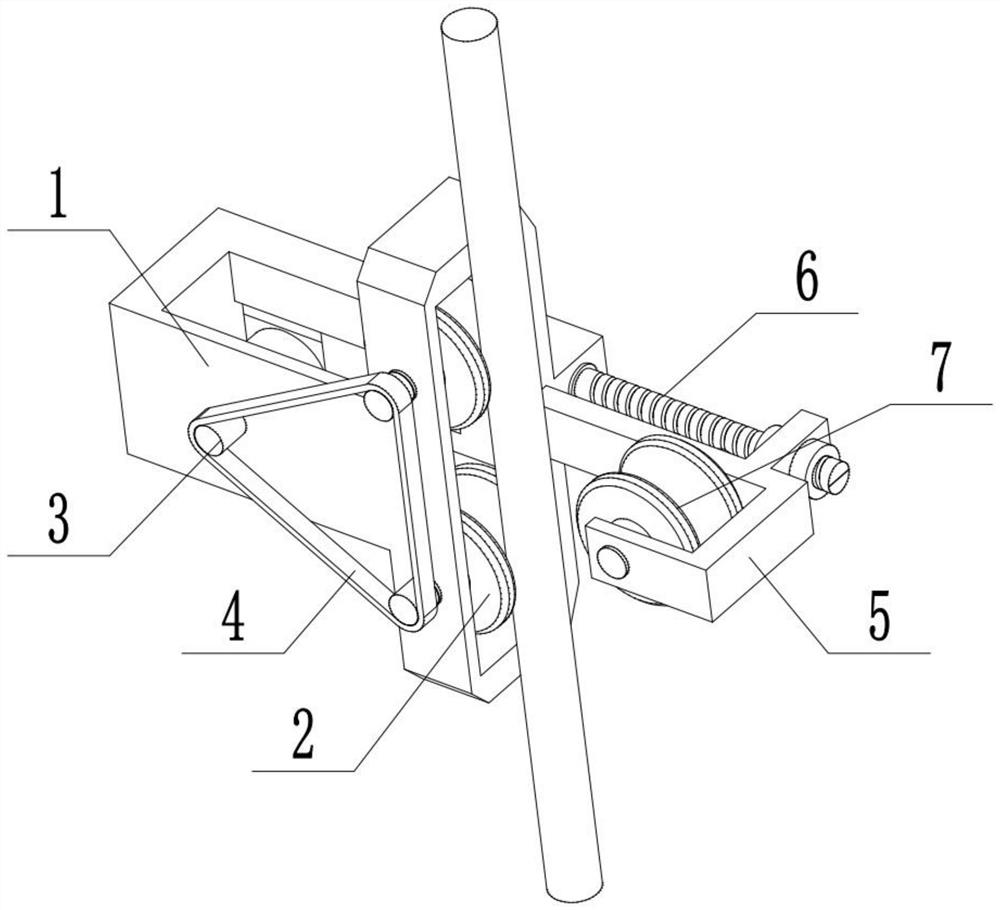

[0024] figure 1 It is a schematic diagram of the overall structure of the device; the driving wheel 2 is rotated and matched with the support frame 1, the sliding frame 5 is slidably matched with the support frame 1, the support 8 is fixed on the support frame 1, the fixing groove 9 is fixed on the support frame 1, and the moving groove 10 is connected with the fixed groove 9 through the rack 11, two rotating pieces 13 are provided, the rotating piece 13 is rotatably matched with the fixed groove 9, the rotating piece 13 is rotatably matched with the moving groove 10, the upper frame 19 is rotatably matched with the bracket 8, and clamped The frame 20 is slidingly matched with the upper frame 19 , the insulating groove 23 is fixed on the upper frame 19 , and the electrode frame 25 is connected with the insulating groove 23 . Before welding the steel bar, the equipment is first connected to the lower steel bar, and the steel bar is in contact with the driving wheel 2 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com