Equipment and method for shaping and processing bottom leather heel surface leather in shoe production

A processing equipment and heel technology, which is applied in the field of shaping and processing equipment for sole leather and heel skin, can solve the problems of lowering the temperature of the sanding position, cooling and removing impurities at the place that cannot be sanded, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

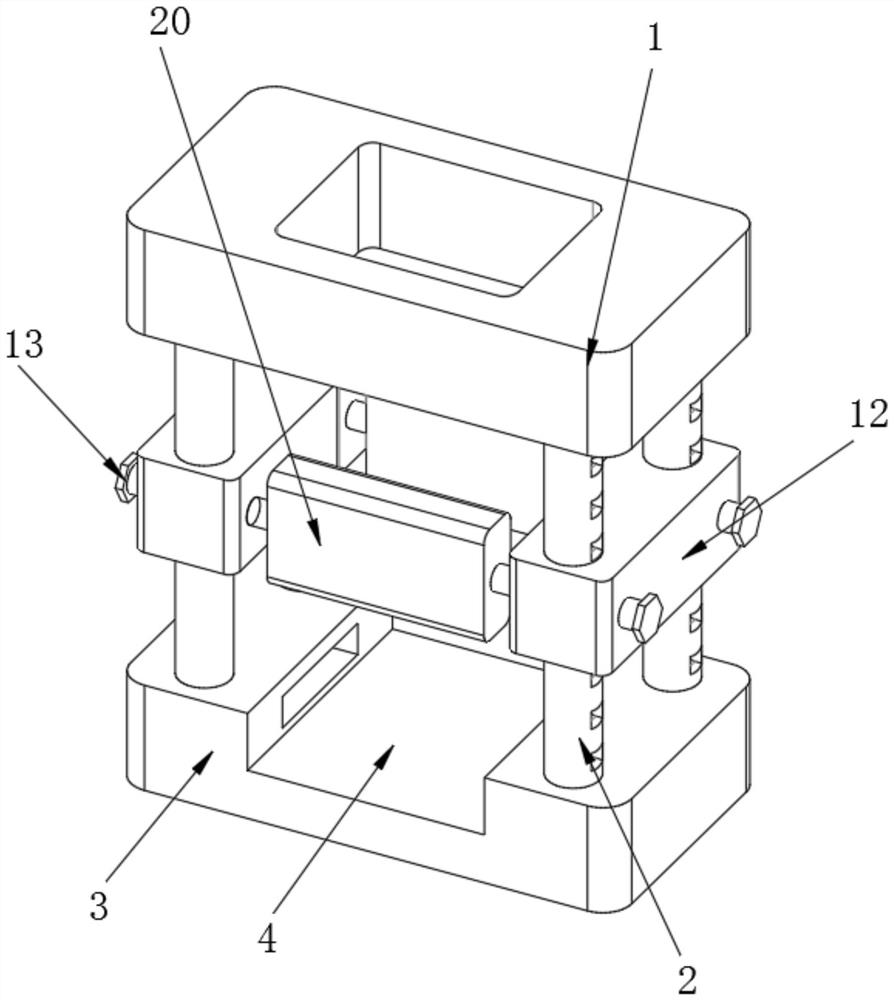

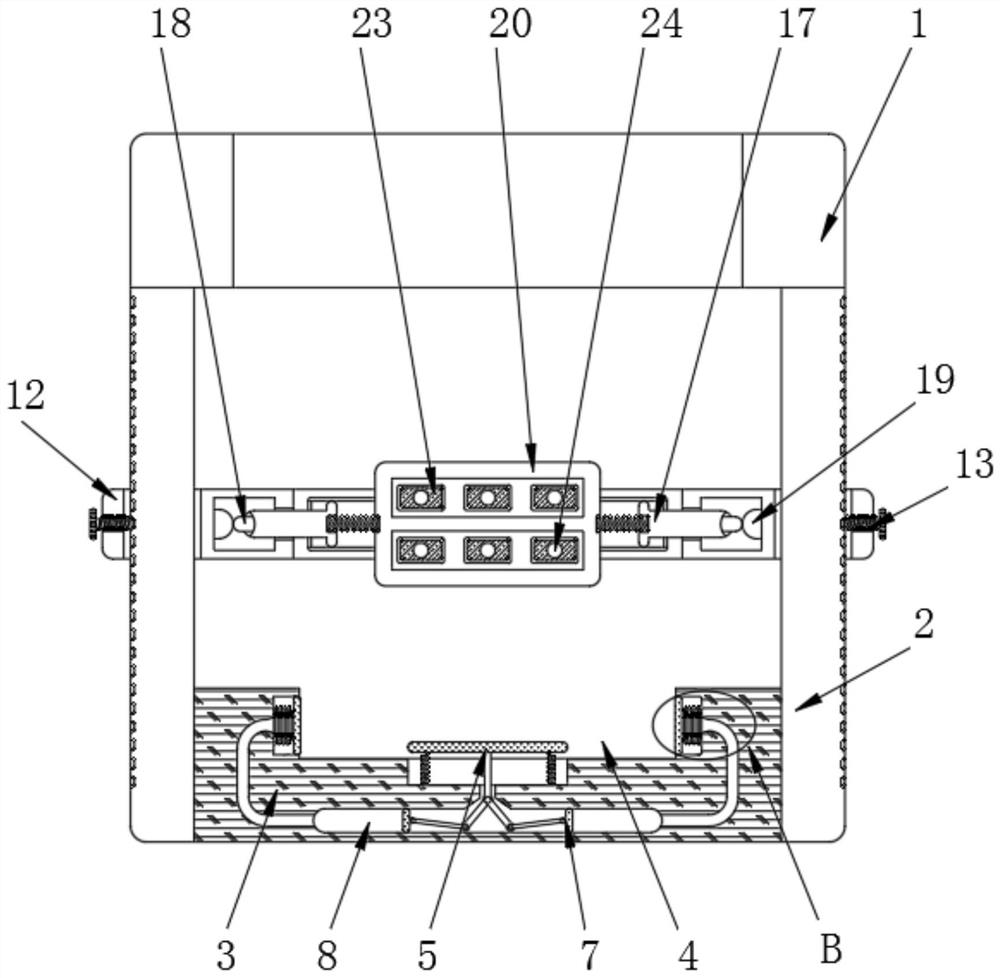

[0043] see Figure 1-3 , a kind of equipment for shaping and processing bottom leather and heel skin in shoe production, comprising a frame 1, the bottom of the frame 1 is fixedly connected with a support frame 2, the side wall of the support frame 2 is provided with grooves, and the grooves The diameter is the same as that of the locking bolt 13 , and the locking bolt 13 can engage the mounting frame 12 and the support frame 2 to fix the mounting frame 12 when rotating inwardly.

[0044] The end of the support frame 2 away from the frame 1 is fixedly connected with a base 3, and the inside of the base 3 is provided with a placement groove 4, and the inside of the center of the placement groove 4 is slidably connected with a pressing plate 5, and the bottom of the pressing plate 5 is rotatably connected with a movable connecting rod 6, The end of the movable connecting rod 6 away from the pressure plate 5 is rotatably connected with a blocking block 7, the blocking block 7 is ...

Embodiment 2

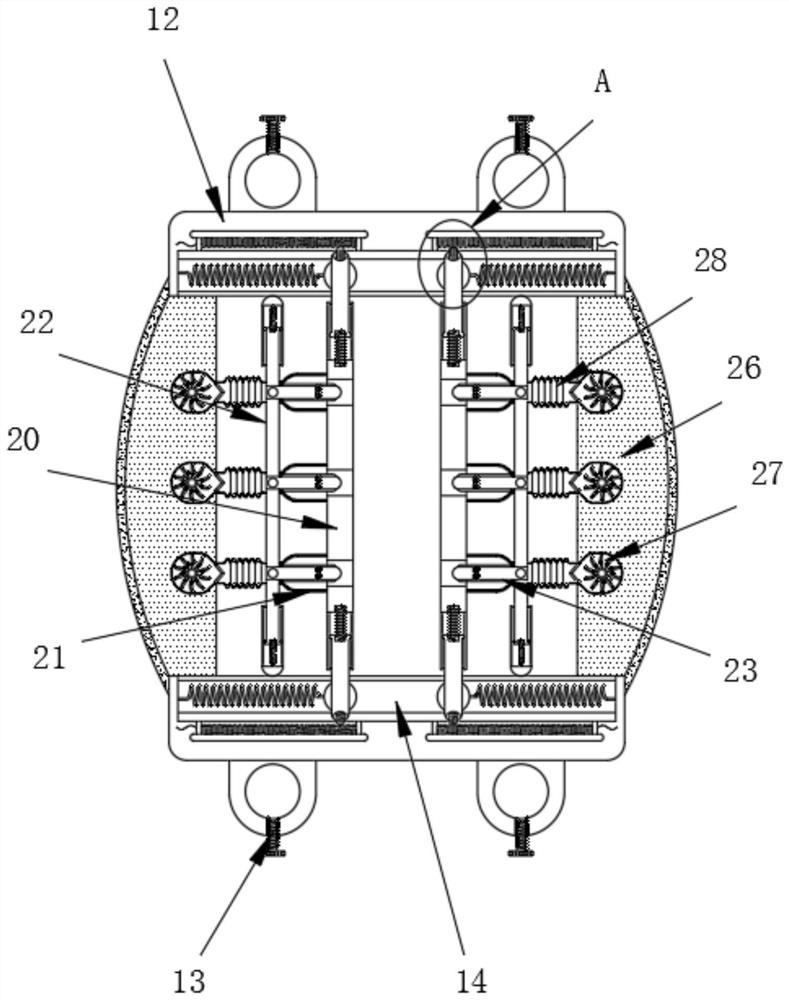

[0047] see Figure 2-4 , the surface of the support frame 2 is slidably connected with a mounting frame 12, the top of the mounting frame 12 is threadedly connected with a locking bolt 13, the inside of the side wall of the mounting frame 12 is provided with a chute 14, and the inside of the chute 14 is slidably connected with a slider 15 , the side of the slide block 15 close to the chute 14 is fixedly connected with a return spring 16, the upper surface of the slide block 15 is fixedly connected with a slide bar 17, and the end of the slide bar 17 close to the side wall of the chute 14 is fixedly connected with a metal contact 18, the metal The contact 18 is slidably connected to the surface of the resistance bar 19, and the metal contact 18 is connected with a power supply. The resistance bar 19 is connected with the resistance inside the air pump 27 through a wire. When the metal contact 18 slides to the outer end of the resistance bar 19, the air pump 27 The resistance co...

Embodiment 3

[0049] see Figure 3-7 , the inside of the side wall of the chute 14 is fixedly connected with a resistance strip 19, the outer surface of the sliding rod 17 is slidably connected with a sliding frame 20, the inside of the sliding frame 20 is provided with a through hole, and the elastic chamber 21 is fixedly connected to the side of the through hole, and The elastic cavity 21 is a hollow airtight cavity made of rubber, and the elastic cavity 21 can be squeezed to slide to one side of the sliding frame 20 .

[0050] The side of the sliding frame 20 away from the center of the mounting frame 12 is fixedly connected with an elastic cavity 21, and the end of the elastic cavity 21 away from the sliding frame 20 is fixedly connected with a push plate 22, and the side of the pushing plate 22 close to the elastic cavity 21 is fixedly connected with a clamping Block 23, the clamping block 23 is fixedly connected to the inside of the elastic cavity 21, and the clamping block 23 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com