Preparation method of potato and rice mixed powder rice steamed sponge cake

A technology of potato whole flour and mixed flour, which is applied in the field of food processing, can solve the problems of cumbersome preparation steps and many additives, and achieve the effect of improving nutritional value, less additives, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

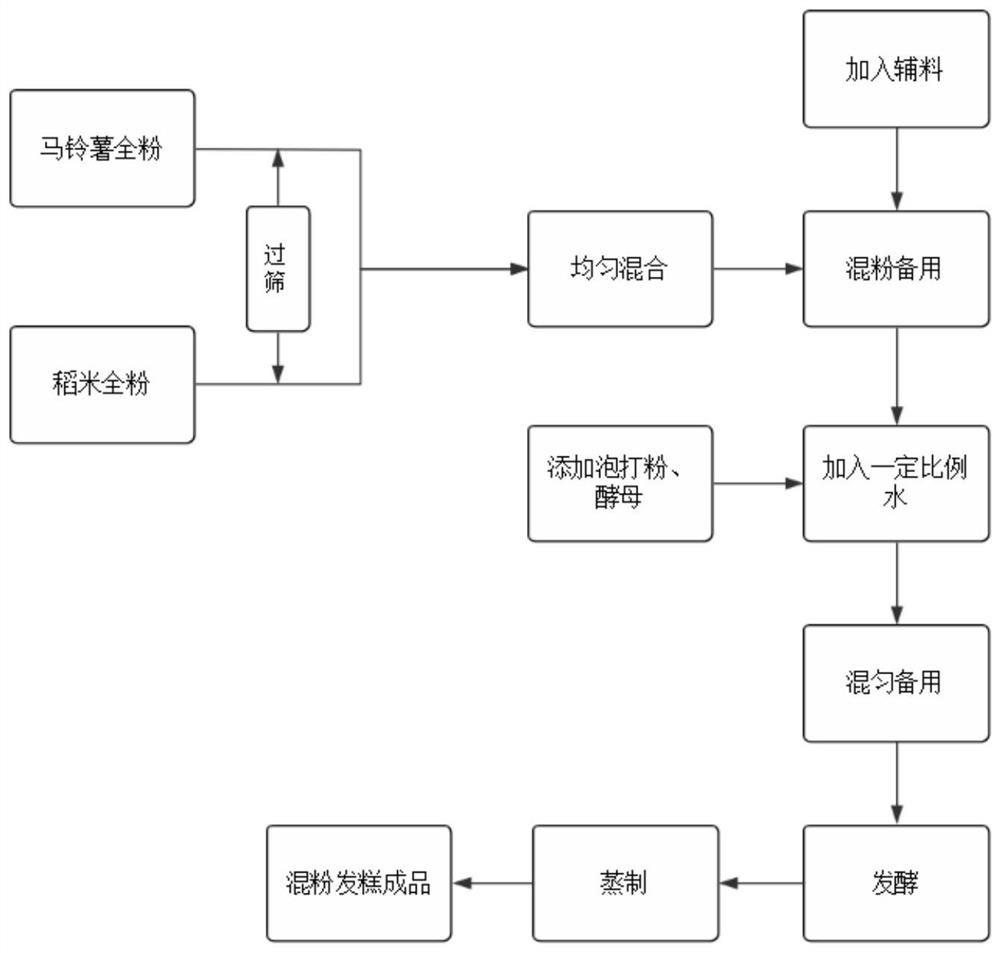

Method used

Image

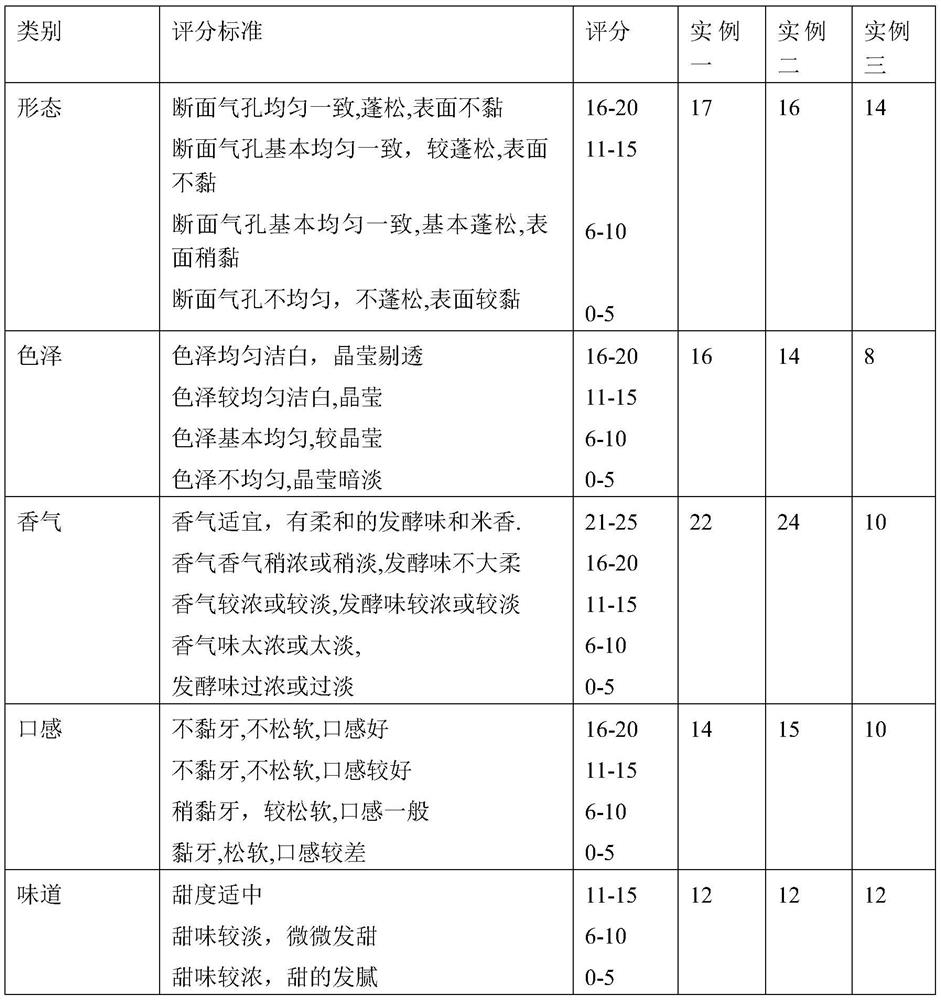

Examples

Embodiment 1

[0022] A potato and rice mixed powder rice, made from the weight of the following weight: 20 parts of potato powder, 80 rice noodles, 18 white sugar, 2 bubble powder, 2 yeast.

[0023] The production method in this embodiment is:

[0024] (1) Sifting powder: Eight of the 80 mesh sieves with rice and rice, take 20 parts of the screened potato, and 80 rice noodles.

[0025] (2) Mix: Take the raw material (18 parts of white sugar, 2 parts of white sugar) by weight, and mix all raw materials.

[0026] (3) Preparation of yeast agents: Take 2 copies of yeast with hydration of hydration of 35 ° C.

[0027] (4) and face: Add yeast and water to the mixed powder raw material to face, and to a viscous semi-paste.

[0028] (5) Fair Fermentation: In a wake-off box of a temperature of 36 ° C, cover the gauze fermentation for 2 h.

[0029] (6) Fermentation is completed: when the dough is expanded to about one-third of the forefront of the dough.

Embodiment 2

[0032] A potato and rice mixed powder rice, made of weight of the following weight: 30 pieces of potato powder, 70 rice noodles, 18 white sugar, 2 bubble powder, 2 yeast.

[0033] The production method in this embodiment is:

[0034] (1) Sifting powder: Eight of the 80 mesh sieves with rice and rice, take 20 parts of the screened potato, and 80 rice noodles.

[0035] (2) Mix: Take the raw material (18 parts of white sugar, 2 parts of white sugar) by weight, and mix all raw materials.

[0036] (3) Preparation of yeast agents: Take 2 copies of yeast with hydration of hydration of 35 ° C.

[0037] (4) and face: Add yeast and water to the mixed powder raw material to face, and to a viscous semi-paste.

[0038] (5) Fair Fermentation: In a wake-off box of a temperature of 36 ° C, cover the gauze fermentation for 2 h.

[0039] (6) Fermentation is completed: when the dough is expanded to about one-third of the forefront of the dough.

Embodiment 3

[0042] A potato and rice mixed powder rice, made of weight of the following weight: 40 parts of potato powder, 60 rice rice flour, 18 white sugar, 2 bubble powder, 2 yeast.

[0043] The production method in this embodiment is:

[0044] (1) Sifting powder: Eight of the 80 mesh sieves with rice and rice, take 20 parts of the screened potato, and 80 rice noodles.

[0045] (2) Mix: Take the raw material (18 parts of white sugar, 2 parts of white sugar) by weight, and mix all raw materials.

[0046] (3) Preparation of yeast agents: Take 2 copies of yeast with hydration of hydration of 35 ° C.

[0047] (4) and face: Add yeast and water to the mixed powder raw material to face, and to a viscous semi-paste.

[0048] (5) Fair Fermentation: In a wake-off box of a temperature of 36 ° C, cover the gauze fermentation for 2 h.

[0049] (6) Fermentation is completed: when the dough is expanded to about one-third of the forefront of the dough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com