Mounting bracket, encoder connecting structure and motor

A technology for installing brackets and encoders, which is applied to structural connections, electromechanical devices, electrical components, etc., can solve the problems of poor verticality of the encoder and affect the work of the encoder, and achieve the effect of ensuring normal operation and meeting the requirements of installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

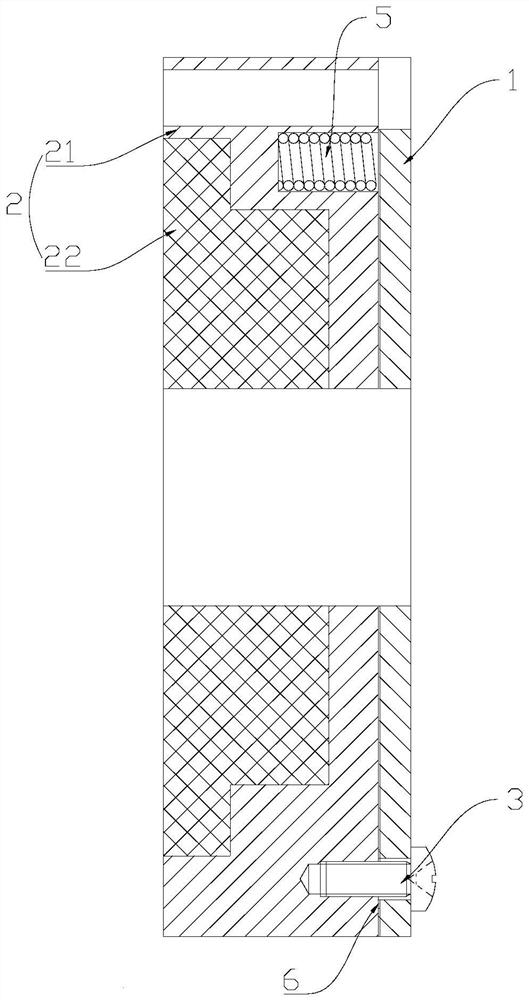

[0042] Such as Figure 3-Figure 6 As shown, this embodiment provides a mounting bracket, including a base 2 fixed to the assembly in the motor and a mounting part 1 with a mounting surface 11, wherein: there is a gap between the base 2 and the mounting part 1, The installation part 1 has a fixed part and a movable part, and the fixed part is locked with the base 2; adjusting the position of the movable part can change the distance between the movable part and the base 2, and then make the mounting surface 11 perpendicular to the motor shaft 402.

[0043] Wherein, the mounting part 1 includes a mounting plate, and a certain gap is set between the base 2 and the mounting plate, which can reserve a certain space for the position adjustment of the movable parts.

[0044] Typically, the "assembly" inside the motor is the rear endshield inside the motor, see Figure 7 As shown, the mounting bracket is fixed on the rear end cover, and the encoder is fixed on the mounting surface 11 ...

Embodiment 2

[0067] Such as figure 2 , The code disc 101 is directly locked on the motor shaft 402, and the heat and vibration generated by the motor winding and the brake are transmitted to the encoder 100, which is not conducive to the long-term stable operation of the encoder.

[0068] In view of the above problems, this embodiment has been improved on the basis of the above embodiments, see Figure 3-Figure 5 As shown, the base 2 of this embodiment includes a connected support plate 21 and a heat insulation plate 22, the support plate 21 is connected to the base 2, at least part of the heat insulation plate 22 can be in contact with the assembly parts in the motor to Prevent the vibration and / or heat of the motor from being transferred to the mounting surface 11 .

[0069]The function of the support plate 21 is to have a certain strength, which can better support the connection base 2 and the installation part 1, and ensure the overall structural strength of the installation bracket....

Embodiment 3

[0077] see Figure 7 As shown, this embodiment provides an encoder connection structure, including the above-mentioned installation bracket, the encoder is fixed on the installation surface 11, and the base 2 is fixedly connected with the assembly parts in the motor. see Figure 7 Specifically, the above-mentioned assembly is usually the rear end cover of the motor, and the base 2 is fixedly connected to the rear end cover of the motor.

[0078] The encoder connection structure of this embodiment can ensure that the encoder is perpendicular to the motor shaft 402 when it is fixed on the installation surface 11 by adjusting the installation bracket when there is an error in the size of the motor end cover, so that the encoder can meet the requirements for the installation space. requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com