Novel door plate locking device and locking method

A locking device and door panel technology, which is applied in the field of medium and high voltage switchgear, can solve problems such as easy arc spraying on the upper and lower sides, hidden dangers to the personal safety of operation and maintenance and maintenance personnel, and inability to lock the door panel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

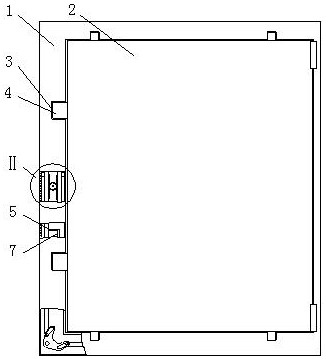

[0026] A novel door panel locking device and locking method, such as Figure 1-2 and Figure 7 shown. It includes a door frame 1 and an inner door 2 hinged on the right side of the door frame 1. The left side, the upper side and the lower side of the door frame 1 are inlaid with a 匚-shaped plate 3 communicating with the inner ring of the door frame 1, and the 匚-shaped plate 3 is provided with Offer the plugboard 4 of jack, described plugboard 4 is fixedly connected on the inner door 2.

[0027] The left side of the door frame 1 is provided with a drive gear 8 that rotates synchronously with the rotary handle 14, and the two sides of the drive gear 8 are vertically provided with racks 9 meshing with the drive gear 8, and the racks 9 are fixedly connected with the corresponding vertical rods 5 respectively. , the vertical rods 5 are vertically slidably connected to the door frame 1. Both the upper side and the lower side of the door frame 1 are horizontally slidably connected...

Embodiment 2

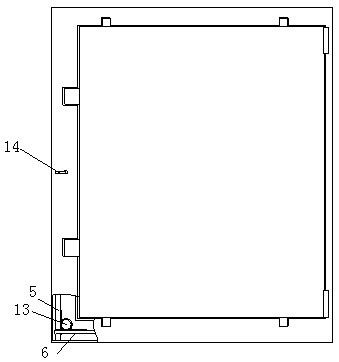

[0034] Example 2, such as Figure 3-4 shown.

[0035] Compared with Embodiment 1, the difference is that the steering mechanism includes an upper gear 13 and a lower gear 15 fixedly connected coaxially, teeth are provided on the cross bar 6, and the cross bar 6 meshes with the upper gear 13, and the vertical bar 5 and the upper gear 13 mesh. The lower gear 15 meshes, the lower vertical bar 5 is located on the left side of the lower lower gear 15, the upper vertical bar 5 is located on the right side of the upper lower gear 15, and the lower horizontal bar 6 and the upper horizontal bar 6 are located on the lower side of the corresponding upper gear 13.

[0036] The downward movement of the lower vertical rod 5 drives the lower lower gear 15 to rotate counterclockwise, which in turn drives the upper gear 13 to rotate counterclockwise, and the counterclockwise rotation of the upper gear 13 drives the lower horizontal rod 6 to move to the right. Similarly, the upper vertical rod ...

Embodiment 3

[0038] Example 3, such as Figure 4-5 shown.

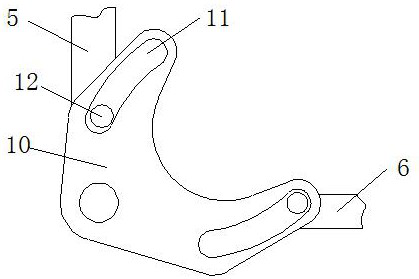

[0039]Compared with Embodiment 1 and Embodiment 2, the difference is that the steering mechanism includes spherical protrusions 16 fixedly connected to the opposite ends of the two vertical bars 5, and the spherical protrusions 16 face the corresponding cross bars 6, and are fixedly connected to the One end of the L-shaped inserting rod 7 on the cross bar 6 is fixedly connected to the spring 17, and the other end of the spring 17 is fixedly connected to the corresponding 匚-shaped plate 3.

[0040] The downward movement of the lower vertical bar 5 (the upward movement of the upper vertical bar 5) drives the protrusions to move together, and then the protrusions approach the corresponding horizontal bar 6 and press the horizontal bar 6 to move to the right, so that the L-shaped insertion rod 7 Insert it into the corresponding jack. Wherein, when the L-shaped inserting rod 7 is moved out of the jack, the lower vertical bar 5 moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com