Inlet gas humidity regulation and control device and method of fuel cell

A fuel cell and control device technology, applied in the direction of fuel cell control, fuel cell, fuel cell additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

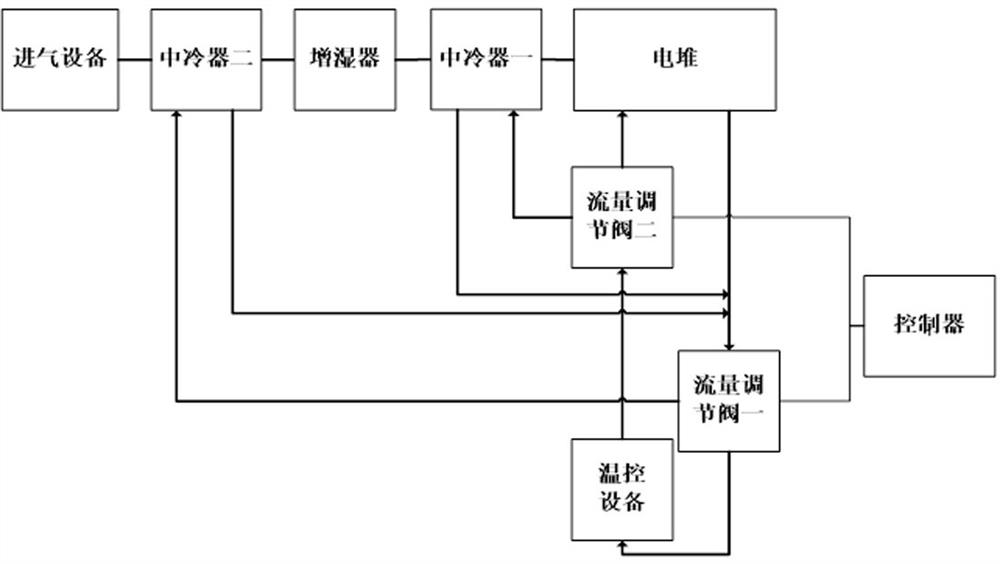

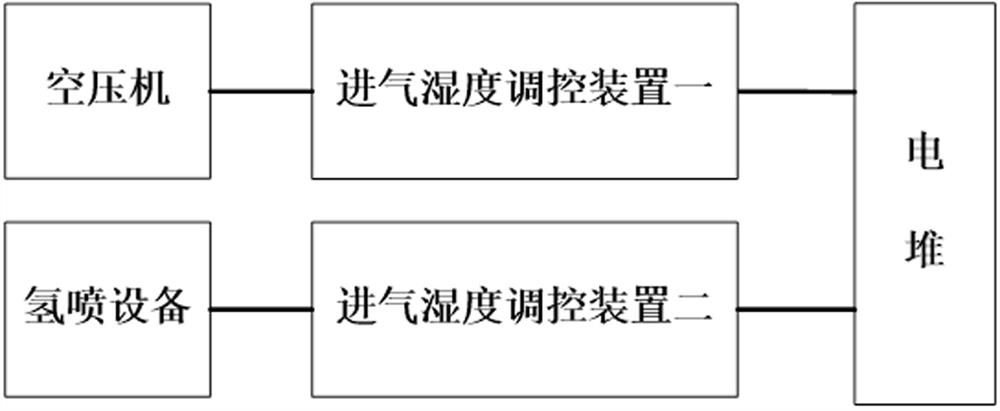

[0058] An embodiment of the present invention discloses an air intake humidity control device for a fuel cell, which is characterized in that it includes flow regulating valves 1 and 2, intercoolers 1 and 2, temperature control equipment, a humidifier, and a controller; ,

[0059] The air inlet of the electric stack (it can be the hydrogen inlet or the air inlet) is connected to the output end of the air inlet device through the first intercooler, the dry area of the humidifier, and the second intercooler; the flow control valve The input end of one is connected with the cooling liquid outlet of the electric stack, the cooling liquid outlet of intercooler one and two, the output end one is connected with the input end of the flow regulating valve two through the temperature control equipment, and the output end two is connected with the intercooler two The coolant inlet is connected; the output end one of the flow regulating valve two is connected with the coolant inlet of t...

Embodiment 2

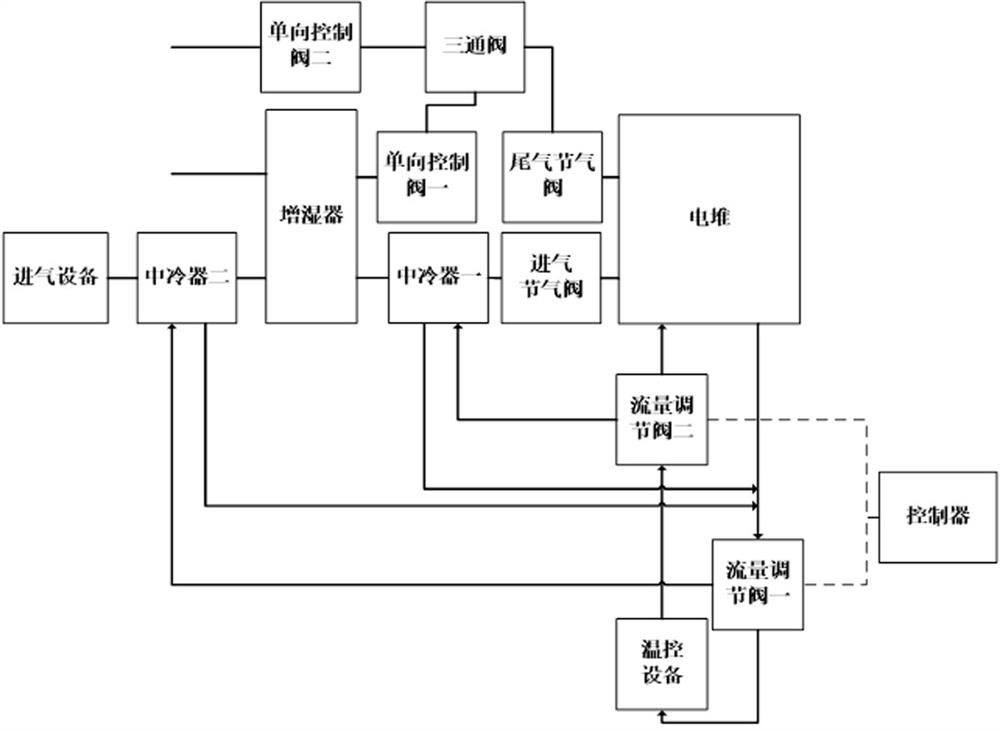

[0066] To improve on the basis of embodiment 1, the air intake humidity control device also includes an air intake throttle valve and an exhaust gas throttle valve.

[0067] Wherein, the inlet of the intake damper is connected with the outlet of the intercooler 1, and the outlet is connected with the inlet of the electric stack, such as Figure 3~4 As shown, the control terminal is connected to the output terminal of the controller; the inlet of the exhaust damper is connected to the exhaust port of the electric stack, the outlet is connected to the inlet of the wet area of the humidifier, and the control terminal is connected to the output terminal of the controller.

[0068] The use of the intake throttle valve and the exhaust gas throttle valve enables a safe sealed environment to be formed inside the stack when the fuel cell is shut down.

[0069] Preferably, the controller further includes a data acquisition unit, a data processing and control unit connected in sequence...

Embodiment 3

[0097] Another embodiment of the present invention discloses a method for controlling humidity using the air intake humidity control device described in Embodiment 1 or 2, comprising the following steps:

[0098] SS1. Real-time monitoring of the humidity of the gas entering the stack to determine whether it is within the preset range;

[0099] SS2. If yes, keep the openings of flow regulating valves 1 and 2 unchanged;

[0100] SS3. If the humidity of the gas entering the stack is lower than the lower limit threshold of the preset range, adjust the openings of flow regulating valves 1 and 2 in real time according to the humidity of the gas entering the stack and the threshold of the preset range, and judge again until the humidity of the gas entering the stack reaches the preset value End humidity control within the range.

[0101] Compared with the prior art, the device provided in this embodiment adjusts the humidity through two-stage intercoolers. The second intercooler ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com