Robot system for realizing intelligent inspection in chemical industry and control method thereof

A robot system, intelligent inspection technology, applied in closed-circuit television systems, instruments, alarms, etc., can solve the problems of no practical application demonstration, limited application conditions, inability to accurately realize gas leakage, etc., and achieve stable, reliable and applicable working performance. Wide range of effects with quick and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

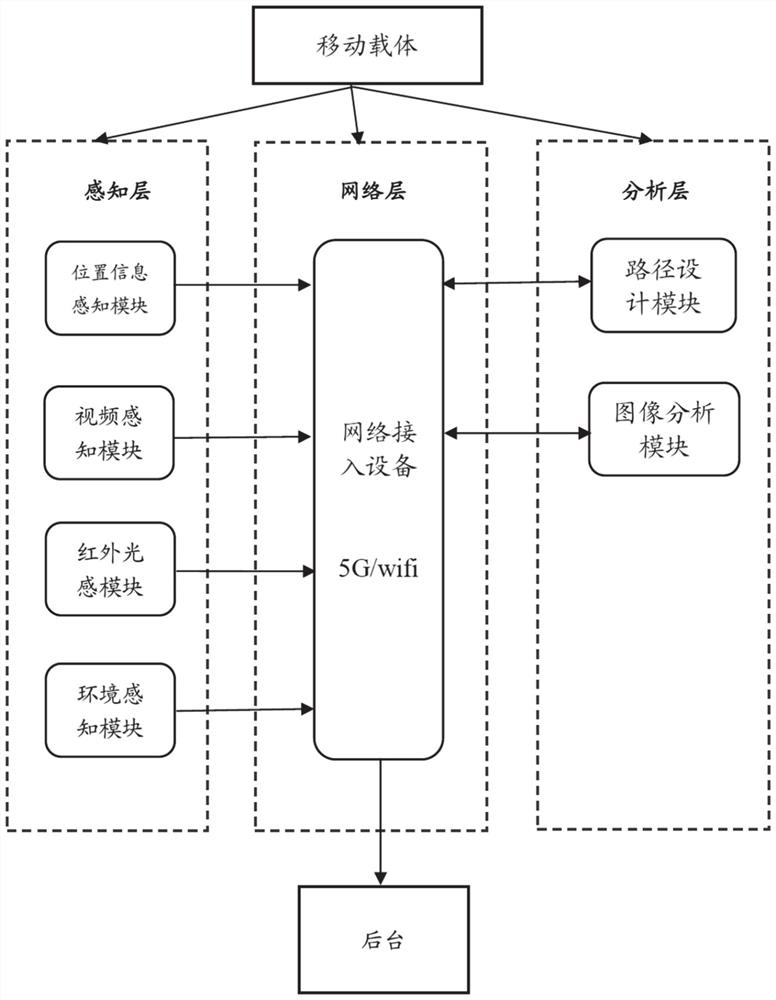

[0045] As a preferred embodiment of the present invention, the perception layer includes:

[0046] A location information sensing module, connected to the network layer, for sensing the location information of the mobile terminal;

[0047] A video sensing module, connected to the network layer, for sensing image information around the location of the mobile terminal;

[0048] An infrared photosensitive module, connected to the network layer, is used to sense the temperature information of objects around the location of the mobile terminal;

[0049] The environment sensing module is connected with the network layer and used for sensing the environmental parameters of the location of the mobile terminal.

[0050] As a preferred embodiment of the present invention, the network layer includes a network access device, which is connected to the collection layer and the application layer, and is used to realize the local area network and public network access of the device, and real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com