Anchor holding power testing method

A test method and technology for anchoring cables, applied in the field of ships and marine engineering, can solve problems such as the limitation of tugboat capacity, and achieve the effect of reducing dependence, low dependence and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

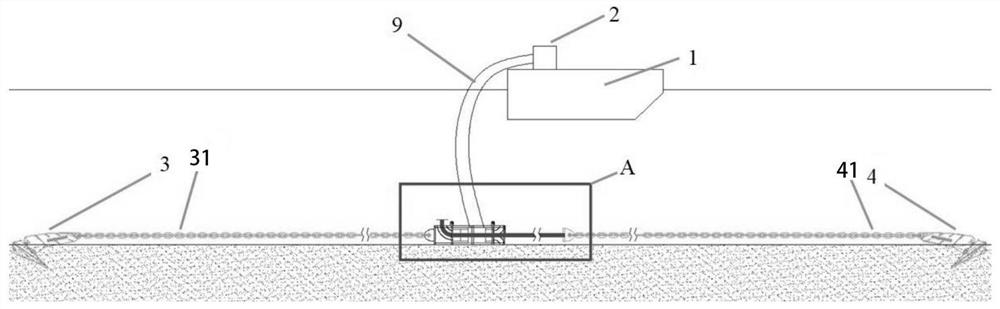

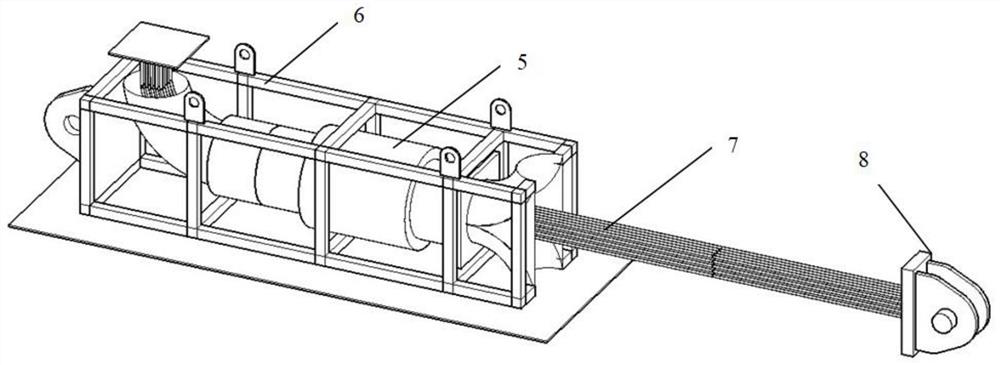

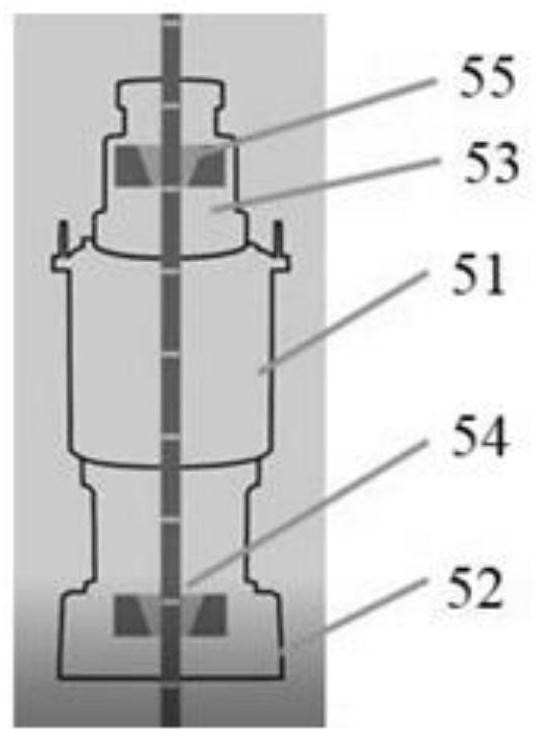

[0024] See Figure 1 to Figure 4 As shown, the anchor holding force test method provided in this embodiment needs to be equipped with a target anchor 3 and its anchor cable 31 for carrying out the anchor holding force test, a temporary anchor 4 and its anchor cable 41 for providing the reaction force required for the test, and a steel strand. Wire tensioner 5, hydraulic power station 2 providing power for steel strand tensioner 5, hydraulic pipeline connecting hydraulic power station 2 and steel strand tensioner 5, providing protection for steel strand tensioner 5 and the support frame 6 supported, the steel strand 7 used in conjunction with the steel strand tensioner 5, the connector 8 connecting the steel strand 7 and the anchor cable, and the operation mother ship 1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com